Tire mounting machine for non-pneumatic tire

A non-pneumatic tire and tire loading technology, which is applied in tire installation, tire parts, transportation and packaging, etc., can solve the problems of low work efficiency, low degree of automation, and inapplicability of non-pneumatic tire installation, and achieve a simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

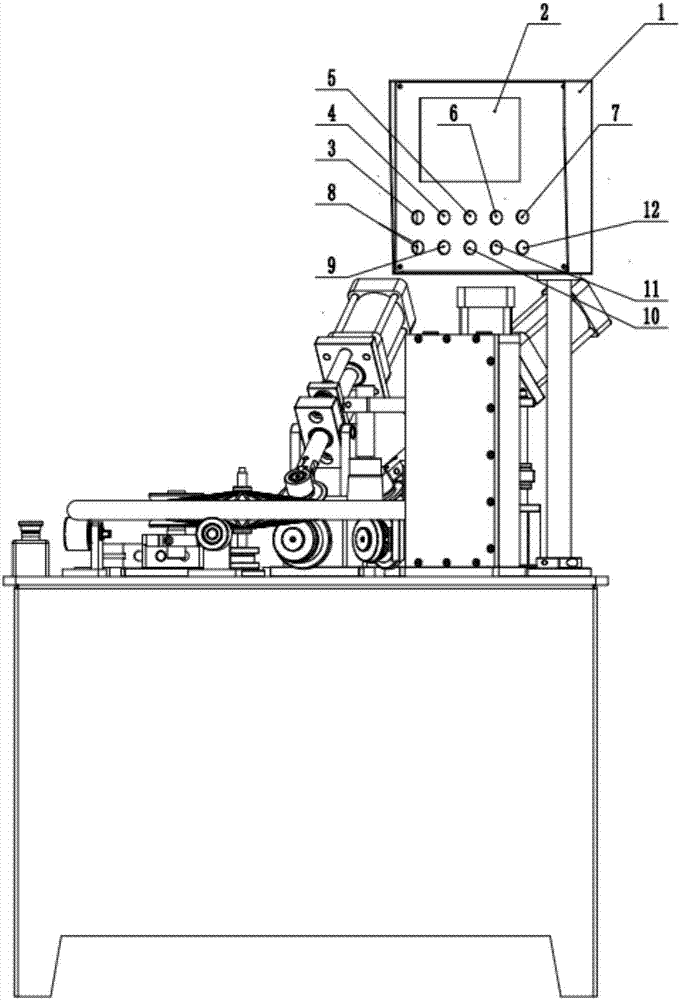

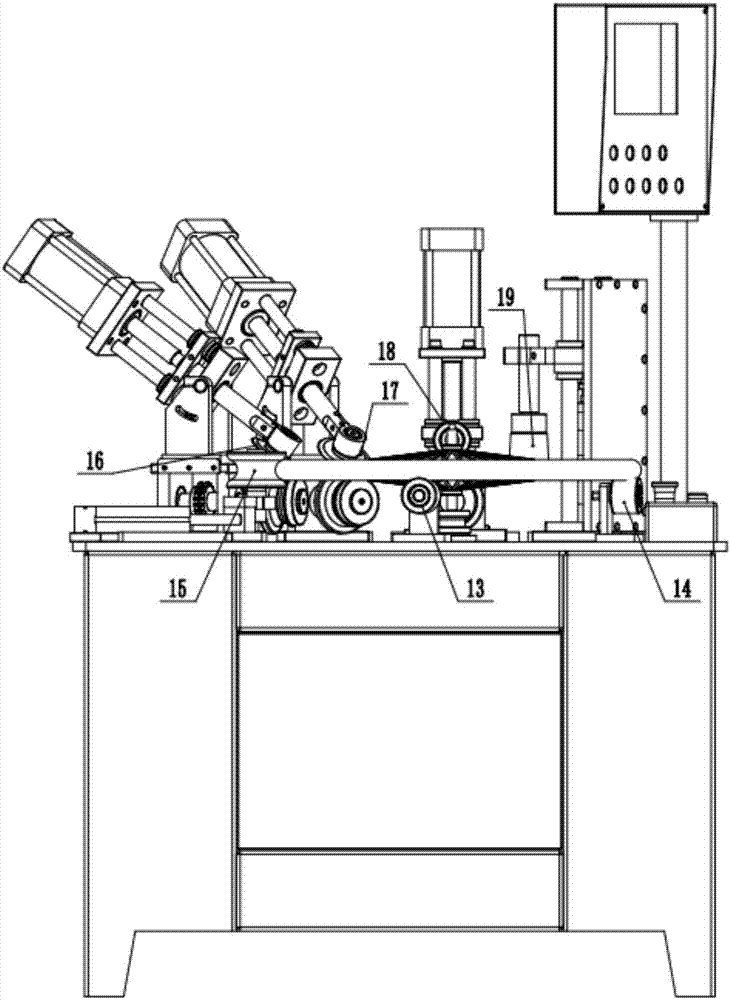

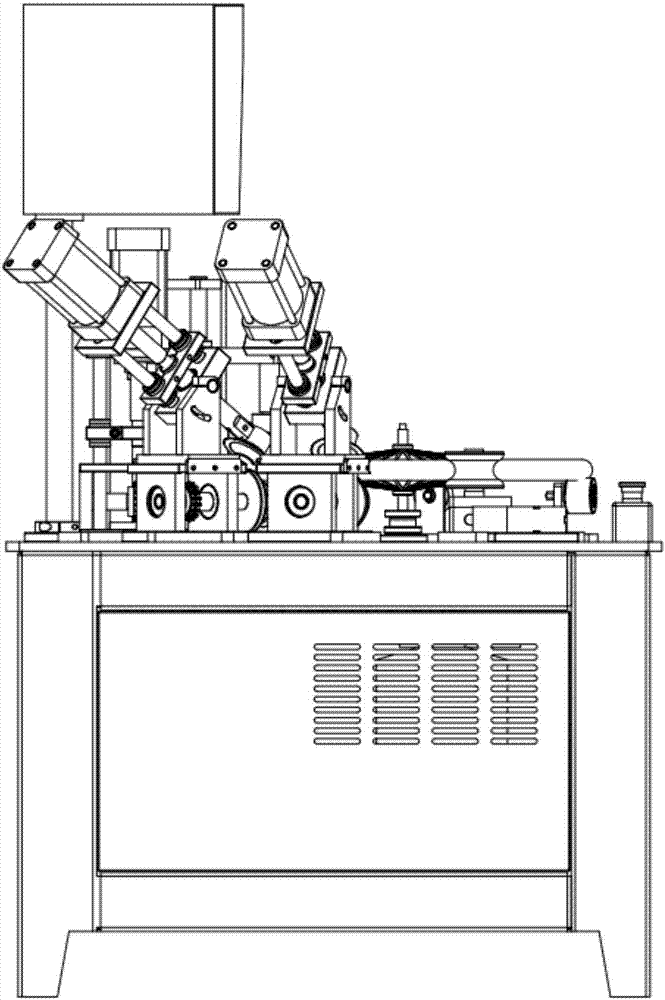

[0016] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

[0017] see Figure 1-4 , an air-free tire loading machine, comprising a tire loading machine body, the tire loading system of the tire loading machine body is mainly composed of supporting wheel A13, supporting wheel B14, correction wheel 15, inserting wheel B16, inserting wheel A17, pressing wheel The wheel 18 and the guide wheel 19 are formed. The support wheel A13 and the support wheel B14 are arranged on the console, and the hub is lifted by the action of the support wheel A13 and the support wheel B14 to keep the rim parallel and consistent. The machine body is equipped with a correction wheel 15, and the loaded tires are corrected and compacted through the action of the correction wheel 15. The tire loading machine body is provided with an insert wheel B16 and an insert wheel A17, and the upper station is missed by the action of the insert wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com