Transparent front cladding layer of motor vehicle

A technology for motor vehicles, front packs, applied in the direction of vehicle components, vehicle safety arrangements, removable outer jackets, etc., can solve problems such as high fuel consumption, adequate cooling of the air conditioning system is not very effective, heating the interior of the vehicle, etc., to achieve simplification effect of repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

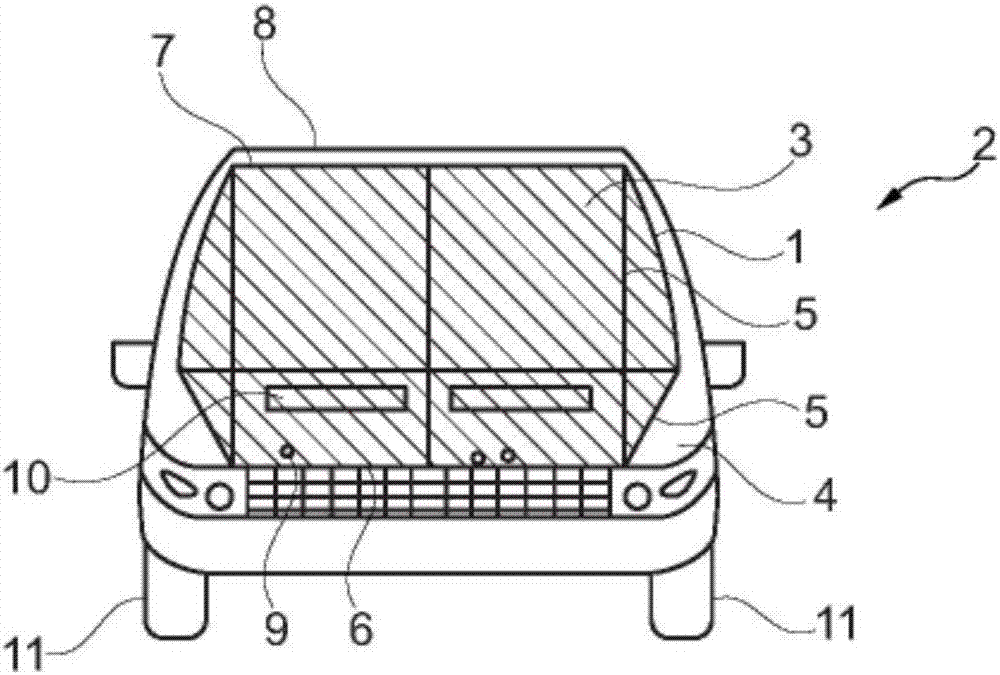

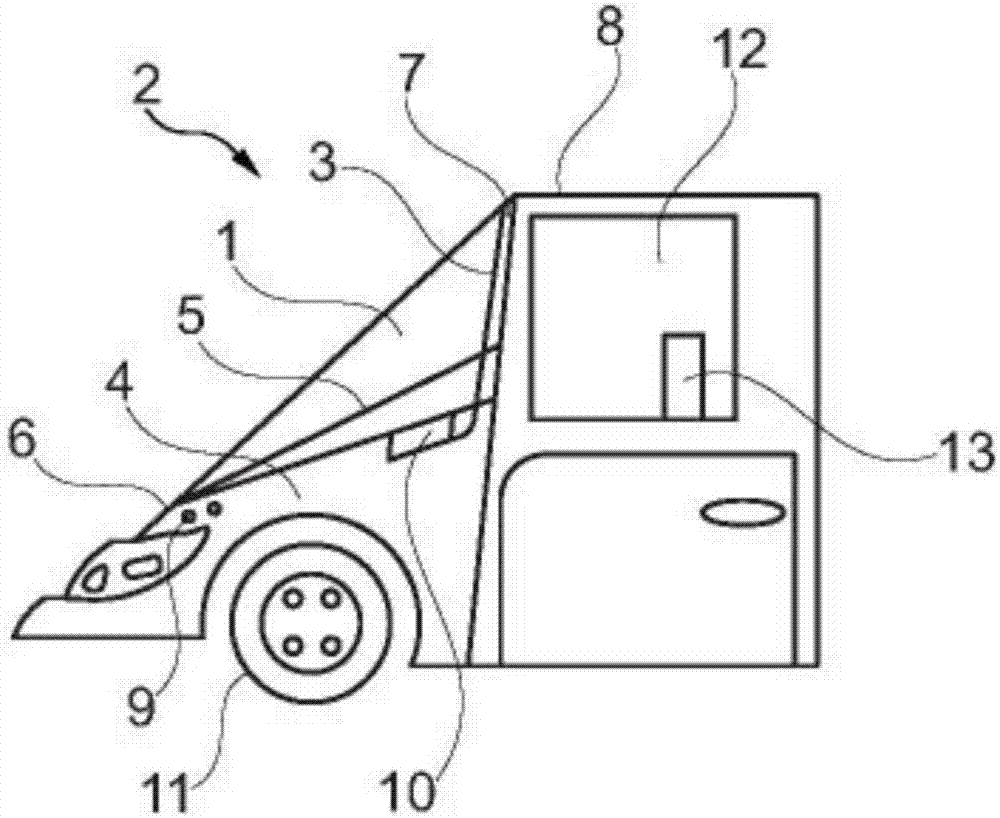

[0022] according to figure 1 , the front cladding 1 is arranged in front of the motor vehicle 2 . The front cladding 1 is arranged over the region of the windscreen 3 and the bonnet 4 of the motor vehicle 2 . The front cladding 1 is transparent, i.e. clear, and may be composed of any transparent material with sufficient stability at low thickness to withstand the wind from driving or the impact of small objects on the front cladding 1 at high speeds. The case does not tear under load, but at the same time is flexible. Preferred materials are eg polymers. The thickness of the front cladding is preferably less than 1 mm, more preferably less than 0.5 mm, more preferably less than 0.1 mm, more preferably less than 0.01 mm, more preferably less than 0.001 mm. Particularly preferred is the well-known thickness of one atomic layer from carbon-modified graphene.

[0023] The material of the front cladding 1 has reinforcing struts 5 which preferably consist of carbon fibers or at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com