Method for preparing silver sulfide quantum dots under normal pressure and temperature

A technology of quantum dots and silver sulfide, applied in the field of preparation of silver sulfide quantum dots, to achieve high photothermal effect, good photoluminescence characteristics, and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] ①Ag 2 Preparation of O nanoparticles: the AgNO 3 Add the powder into deionized water to make the concentration reach 5g / L, stir, and ultrasonically disperse for 30min to make the AgNO 3 Completely dissolve, and under 50W, 40kHz ultrasonic conditions, add dropwise NaOH solution with a concentration of 0.1M to make the pH of the obtained silver nitrate aqueous solution = 14; filter, collect the product, wash, and dry at 70°C for 12 hours to obtain a brown powder. Ag 2 O nanoparticles;

[0024] ② Synthesis of silver sulfide quantum dots: the prepared Ag 2 Ultrasonic dispersion of O nanoparticles in deionized water to a concentration of 0.2g / L, magnetic stirring for 10min, and then dropwise adding 0.01mol / L Na 2 The S solution was stirred for 12 hours, ultrasonically dispersed for 30 minutes, centrifuged, the product was collected, and washed to obtain silver sulfide quantum dots.

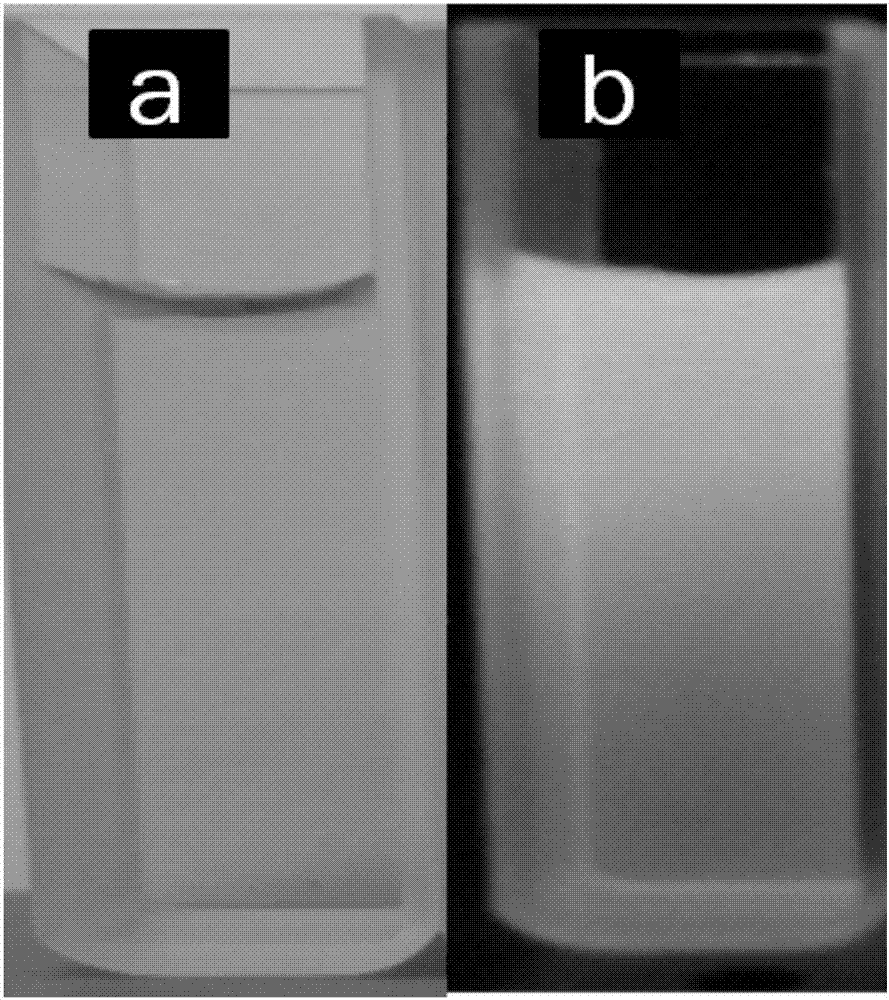

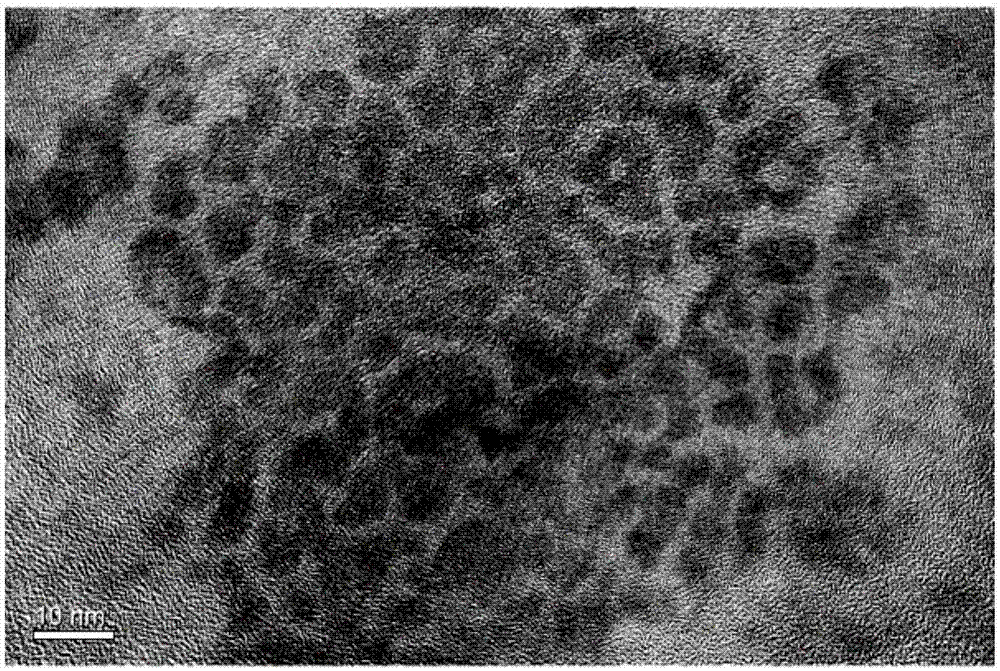

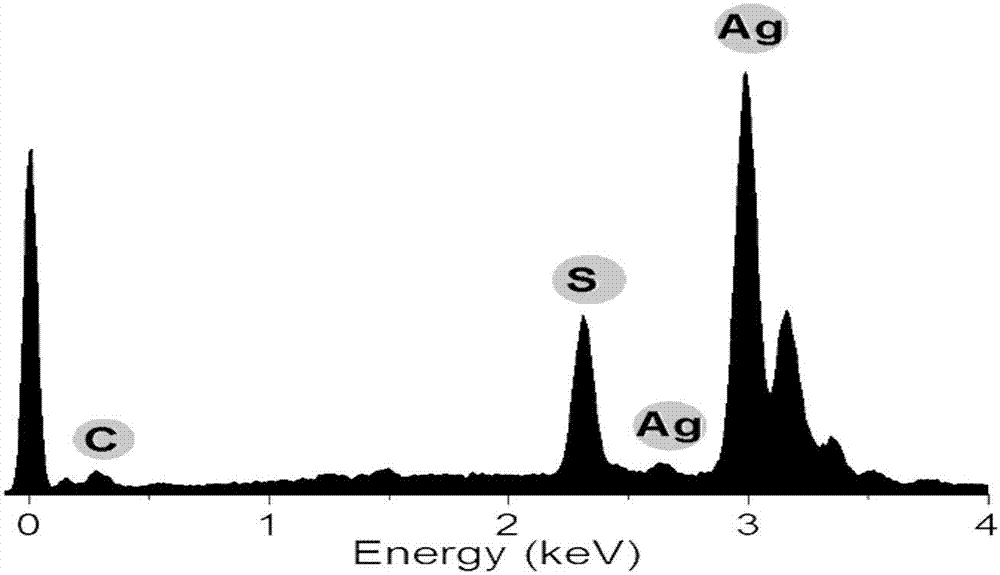

[0025] The above-prepared Ag 2 S quantum dots are identified and detected as follows:...

Embodiment 2

[0036] ①Ag 2 Preparation of O nanoparticles: the AgNO 3 Add the powder into deionized water to make the concentration reach 1g / L, stir, and ultrasonically disperse for 30min to make the AgNO 3 Completely dissolve, and under 50W, 40kHz ultrasonic conditions, dropwise add NaOH solution with a concentration of 0.05mol / L to make the pH of the obtained silver nitrate aqueous solution = 12; filter, collect the product, wash, and dry at 70°C for 10h to obtain a brown powder Ag 2 O nanoparticles;

[0037] ② Synthesis of silver sulfide quantum dots: the prepared Ag 2 Ultrasonic dispersion of O nanoparticles in deionized water to a concentration of 0.1g / L, magnetic stirring for 10min, and then dropwise adding 0.001mol / L Na 2 S solution was stirred for 18 hours, ultrasonically dispersed for 30 minutes, centrifuged, the product was collected, and washed to obtain silver sulfide quantum dots.

Embodiment 3

[0039] ①Ag 2 Preparation of O nanoparticles: the AgNO 3 Add the powder into deionized water to make the concentration reach 3g / L, stir, and ultrasonically disperse for 30min to make the AgNO 3 Completely dissolve, and under 50W, 40kHz ultrasonic conditions, dropwise add NaOH solution with a concentration of 0.2mol / L to make the pH of the obtained silver nitrate aqueous solution = 13; filter, collect the product, wash, and dry at 70°C for 15 hours to obtain a brown powder Ag 2 O nanoparticles;

[0040] ② Synthesis of silver sulfide quantum dots: the prepared Ag 2 O nanoparticles were ultrasonically dispersed in deionized water to a concentration of 1 g / L, magnetically stirred for 10 min, and then added dropwise to the solution with a concentration of 0.04 mol / L Na 2 S solution was stirred for 16 hours, ultrasonically dispersed for 30 minutes, centrifuged, and the product was collected and washed to obtain silver sulfide quantum dots.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com