A kind of curved surface protective film with multifunctional layer and preparation method thereof

A protective film, multi-functional technology, applied in coatings, biocide-containing paints, film/flake adhesives, etc., can solve problems such as affecting the bonding effect, and achieve the effect of increasing the buffer capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

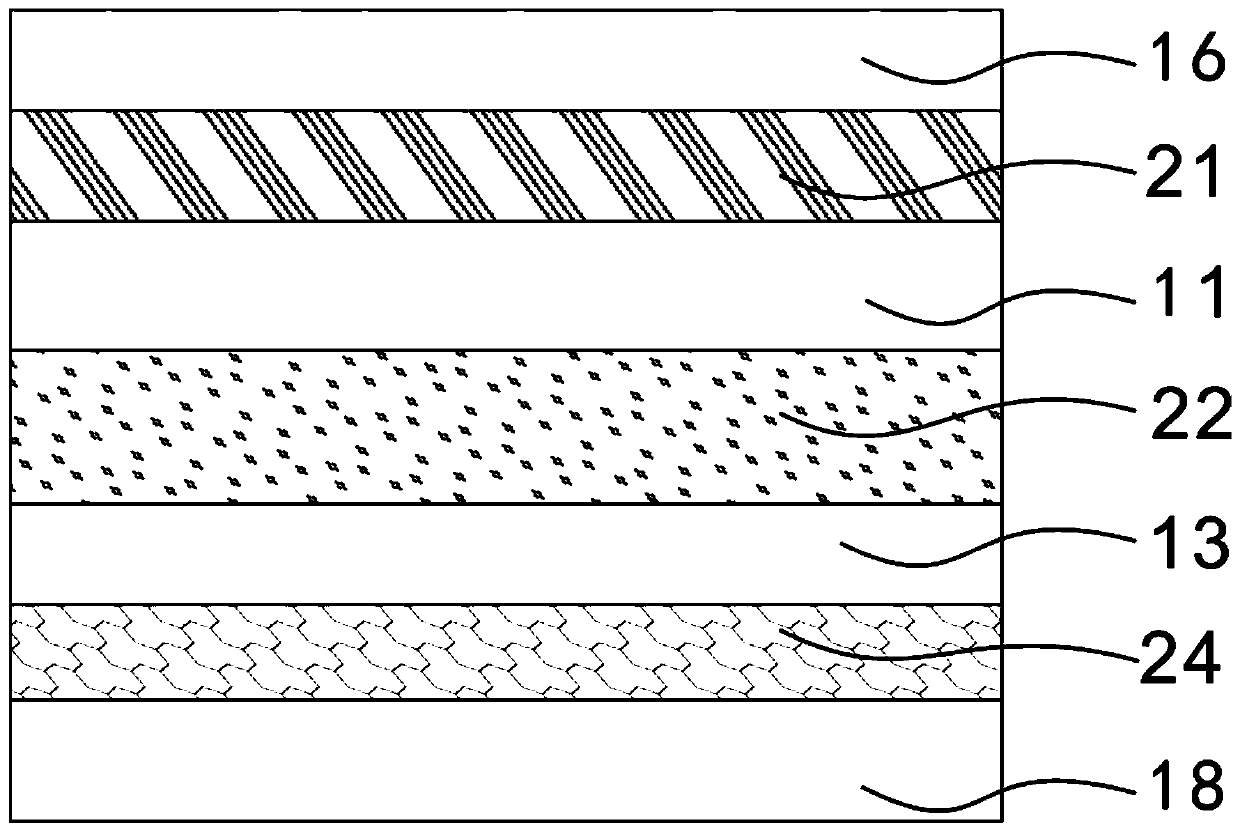

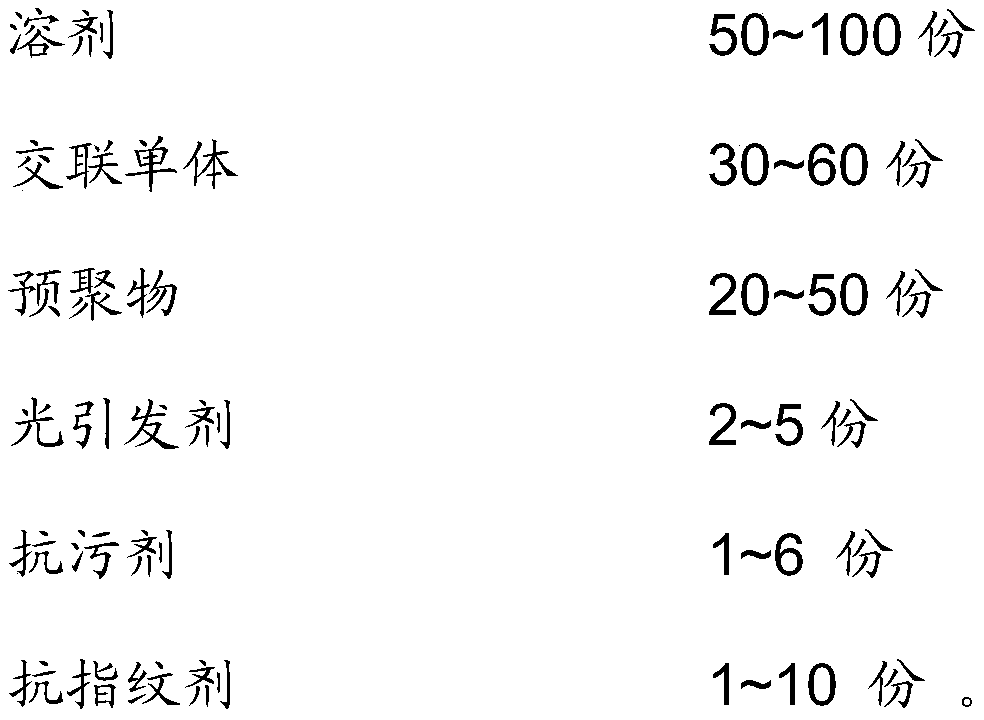

[0069] S1: Use an anilox roller to coat the first substrate 11 (PET) with a thickness of 90 μm, apply anti-fingerprint and anti-fouling UV glue (UV hardening layer 21), and dry it in a 90°C oven with a UV lamp energy of 300-550mj / cm 2 After curing, the coating thickness is 3 μm. The raw material components and weight ratio of the UV hardening layer 21 (with anti-fingerprint and anti-pollution functional layer) are:

[0070]

[0071] Use a Zebra brand oil-based pen to draw a straight line on the UV surface (UV hardening layer 21) of the film. It can be detected from the straight line of the pen and ink to the discontinuity phenomenon. It has the function of hydrophobic, oleophobic and anti-fouling. The better the anti-fouling performance.

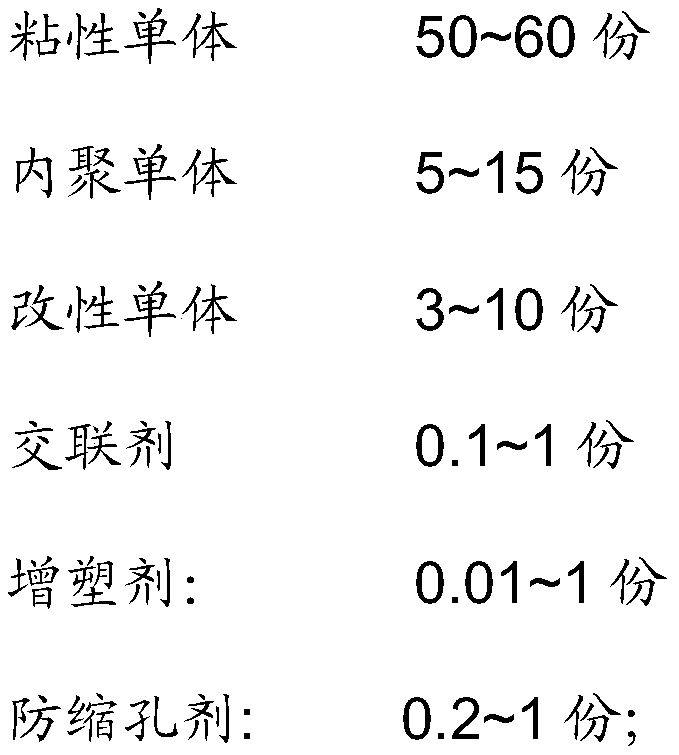

[0072] S2: Use a comma-type scraper to coat another 85 μm-thick second substrate 13 (PET) with a silicone pressure-sensitive adhesive and an anti-blue light agent in a ratio of 100 parts: 9 parts, and the coating thickness is 25 μm. Aft...

Embodiment 2

[0078] S1: Use an anilox roller to coat the first substrate 11 (PET) with a thickness of 100 μm, apply anti-fingerprint and anti-fouling UV glue (UV hardening layer 21), and dry it in a 90°C oven with a UV lamp energy of 300-550mj / cm 2 After curing, the coating thickness is 4 μm. Wherein the raw material composition and weight ratio of the UV curable layer 21 (with anti-fingerprint and anti-pollution functional layer) are:

[0079]

[0080]

[0081] Use a Zebra brand oil-based pen to draw a straight line on the 21st surface of the UV hardened layer of the film. It can be detected from the straight line of the pen and ink to the discontinuity phenomenon. the better.

[0082] S2: Coat another 75 μm thick second substrate 13 (PET) with a silicone pressure-sensitive adhesive with a thickness of 30 μm by using a comma-type scraper, and cure in an oven at 180° C. to obtain a silicone layer 24 . The silicone pressure-sensitive adhesive is a kind of silicone with a relatively ...

Embodiment 3

[0088] S1: Use an anilox roller to coat the first substrate 11 (PET) with a thickness of 100 μm, apply anti-fingerprint and anti-fouling UV glue (UV hardening layer 21), and dry it in a 90°C oven with a UV lamp energy of 300-550mj / cm 2 After curing, the coating thickness is 4-6 μm.

[0089] The raw material components and weight ratio of the UV curable layer 21 (coating liquid with anti-fingerprint and anti-fouling functions) are:

[0090]

[0091] Use a Zebra brand oil-based pen to draw a straight line on the UV surface (UV hardening layer 21) of the film. It can be detected from the straight line of the pen and ink to the discontinuity phenomenon. It has the function of hydrophobic, oleophobic and anti-fouling. The better the anti-fouling performance.

[0092] S2: Coat another 90 μm thick second substrate 13 (PET) with a silicone pressure-sensitive adhesive with a thickness of 25 μm using a comma-type scraper, and cure in an oven at 180° C. to obtain a silicone layer 24 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com