Weft Yarn Detection Method In Air Jet Loom

A detection method, the technology of air-jet looms, applied in looms, textiles, textiles and papermaking, etc., can solve problems such as differences, defects, and inability to detect weft yarns, and achieve the effect of reducing consumption and reducing false detections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

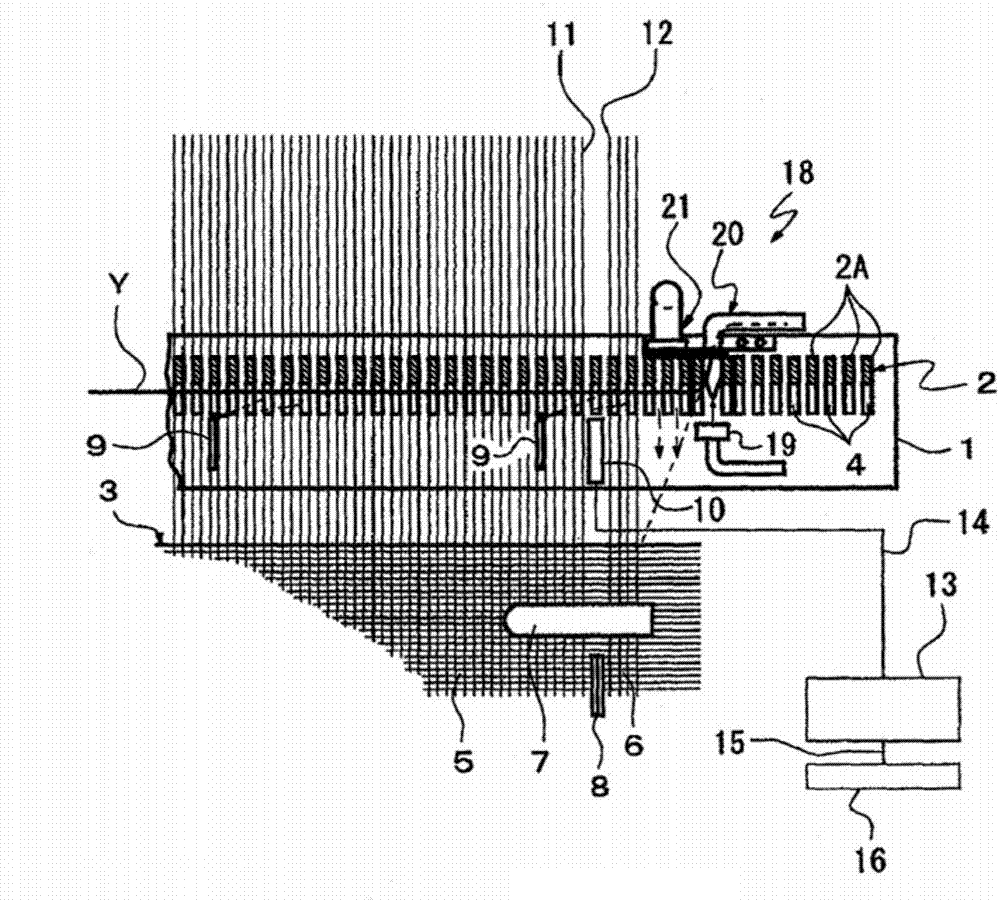

[0021] based on Figure 1 ~ Figure 3 The first embodiment will be described. figure 1 The weaving end on the side opposite to the weft insertion side of the air loom is shown.

[0022] The sley 1 is fixed to a swing shaft (not shown) via a sley foot (not shown), and can swing in the front-back direction of the loom. The deformed reed 2 composed of a plurality of dents 2A attached to the sley 1 has a weft guide passage 4 opened toward the cloth fell 3 side. A temple device 7 is arranged across the weaving end of the fabric 5 and the discarded selvedge 6 so as to straddle both.

[0023] The weft yarn Y passing between the fabric 5 and the discarded selvage 6 passing through the temple device 7 is cut by the cutting tool 8 provided between the fabric 5 and the discarded selvedge 6 . A plurality of auxiliary nozzles 9 for feeding the inserted weft yarn Y are arranged at intervals above the sley 1 .

[0024] Further, on the sley 1, a photoelectric weft sensor 10 constituting a ...

no. 2 approach

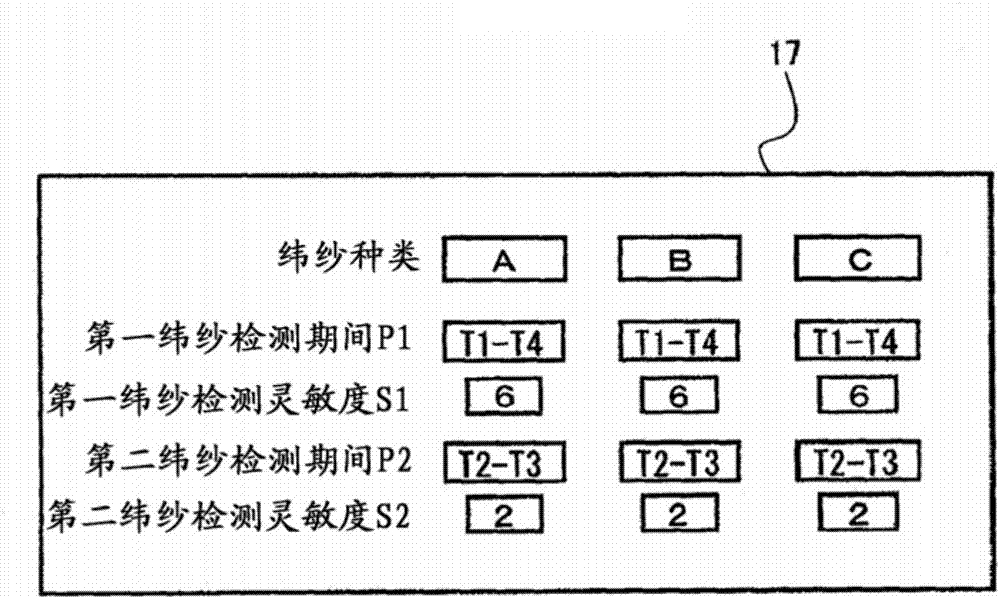

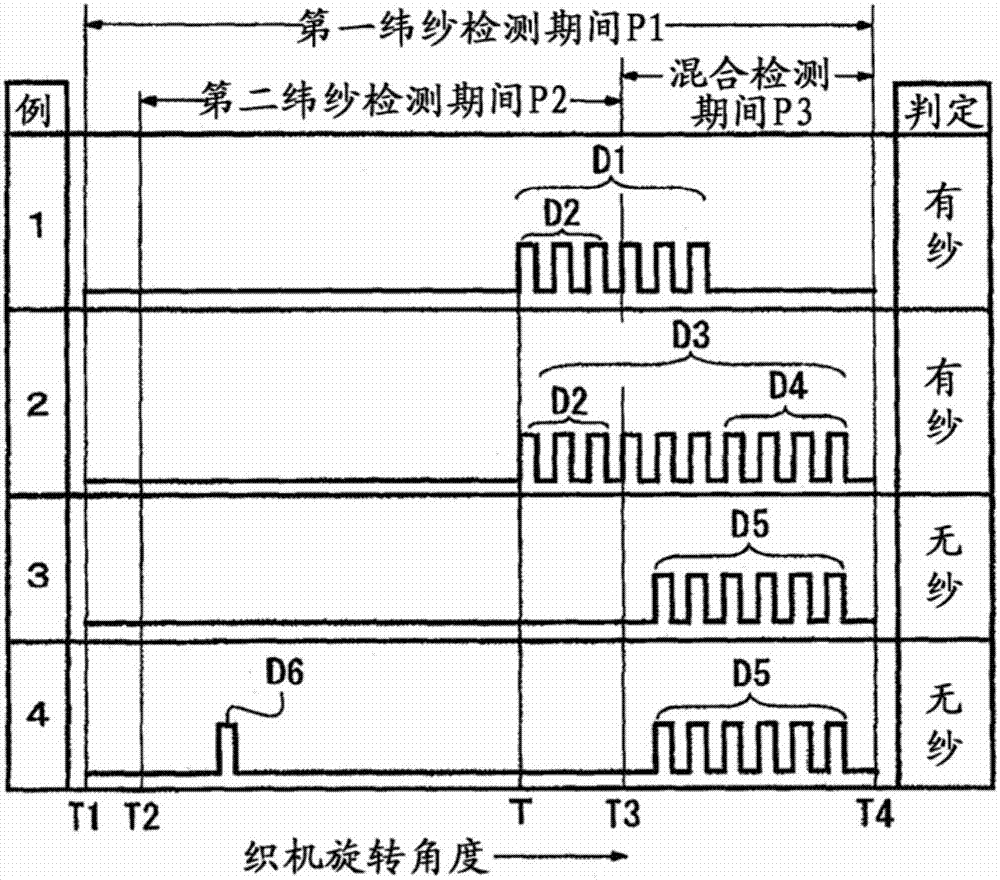

[0051] Figure 4 It is a figure which shows 2nd Embodiment, The same code|symbol is used for the same structure as 1st Embodiment, and detailed description is abbreviate|omitted. In the first embodiment, the light receiving signal of the photoelectric weft sensor 10 is converted into a pulse signal and sent, and the number of pulses is counted in the control device 13, but in the second embodiment, the photoelectric weft sensor 10 is detected in the control device 13. The configuration is for a period in which the magnitude of the transmitted light reception signal is equal to or greater than the threshold value (sensitivity).

[0052] Such as Figure 4 As shown, the first weft yarn detection period P1 and the second weft yarn detection period P2 are set in the control device 13 . The period during which the light reception signal is equal to or greater than the threshold value (sensitivity) is a period D7 in the first weft detection period P1, and a period D8 in the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com