Exhaust fan installation structure in fabric processing arrangement device

A technology of installation structure and exhaust fan, which is applied in the field of machinery, can solve problems such as pipeline collision, affect the finishing effect, and affect the dust removal efficiency, and achieve the effects of reducing the probability of collision, improving dust removal efficiency, and suppressing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

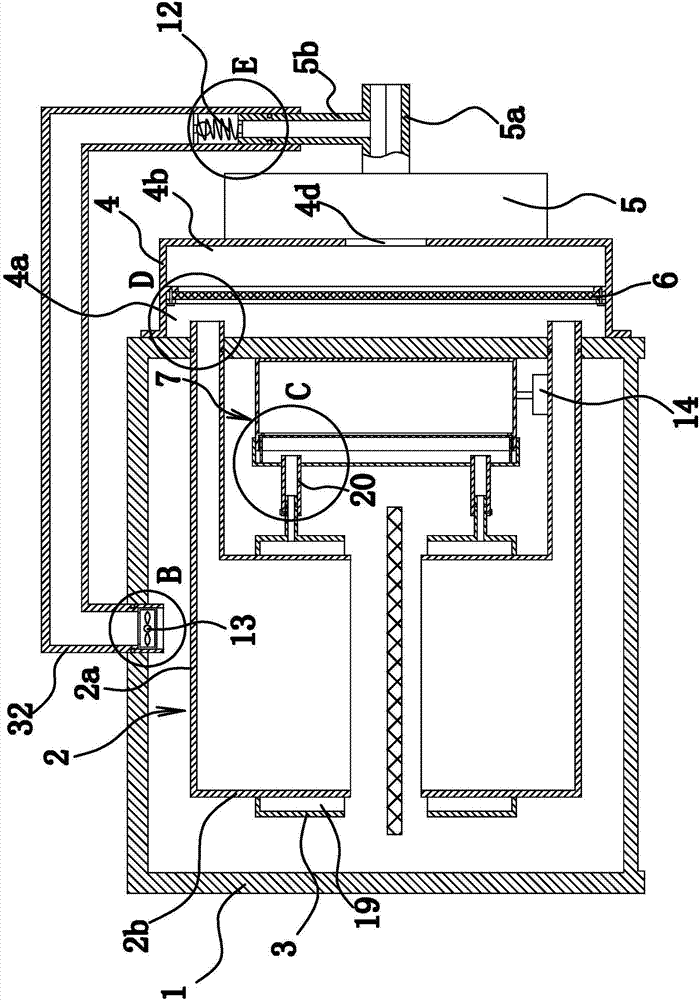

[0025] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

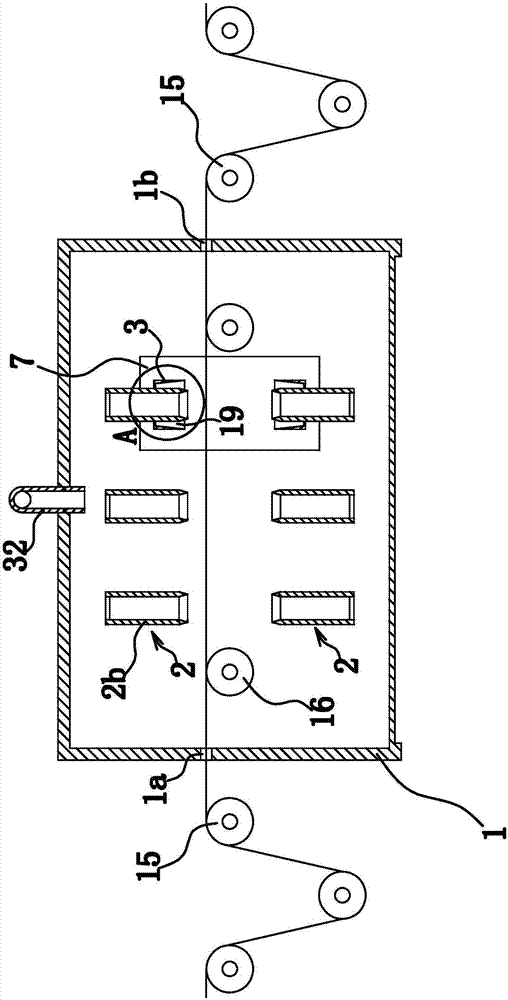

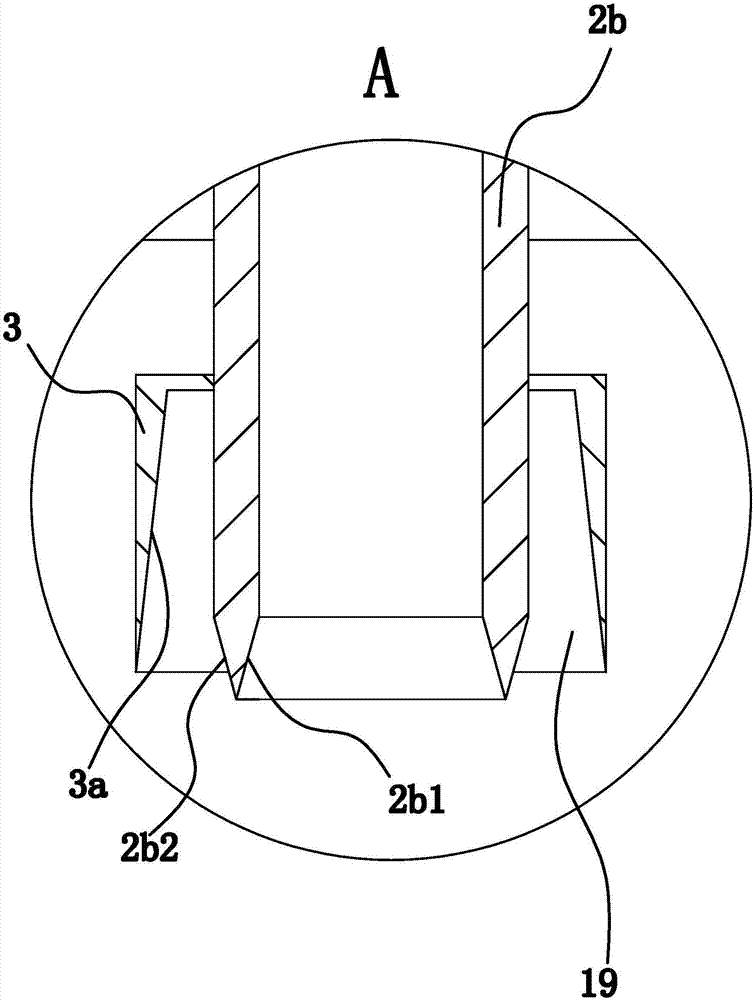

[0026] like Figure 1 to Figure 8 As shown, the fabric fabric processing and finishing equipment consists of a finishing box 1, an exhaust pipe 2, an air extractor 3, a box body 4, a hot air blower 5, a first dust-proof net 6, a gas gathering box 7, a second dust-proof net 8, Support 9, support plate 10, spring one 11, spring two 12, exhaust fan 13, exhaust fan 14 etc. form.

[0027] Wherein, the sorting box 1 is in the shape of a cuboid, and in actual use, the sorting box 1 is arranged along the horizontal direction. The two side walls distributed along the length direction of the finishing box 1 are respectively provided with a cloth inlet 1a and a cloth outlet 1b. It is consistent with the width extension direction of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com