Device for testing pore water pressure

A technology of pore water pressure and pore water pressure gauge, which is applied in the field of foundation soil survey, construction, infrastructure engineering, etc., and can solve the problem that the service life of buried pore water pressure gauge is greatly affected by the environment, cannot be realized, and is difficult to bury Pore water pressure gauge and other issues to achieve the effect of enhancing monitorability, improving safety assurance, and continuous testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

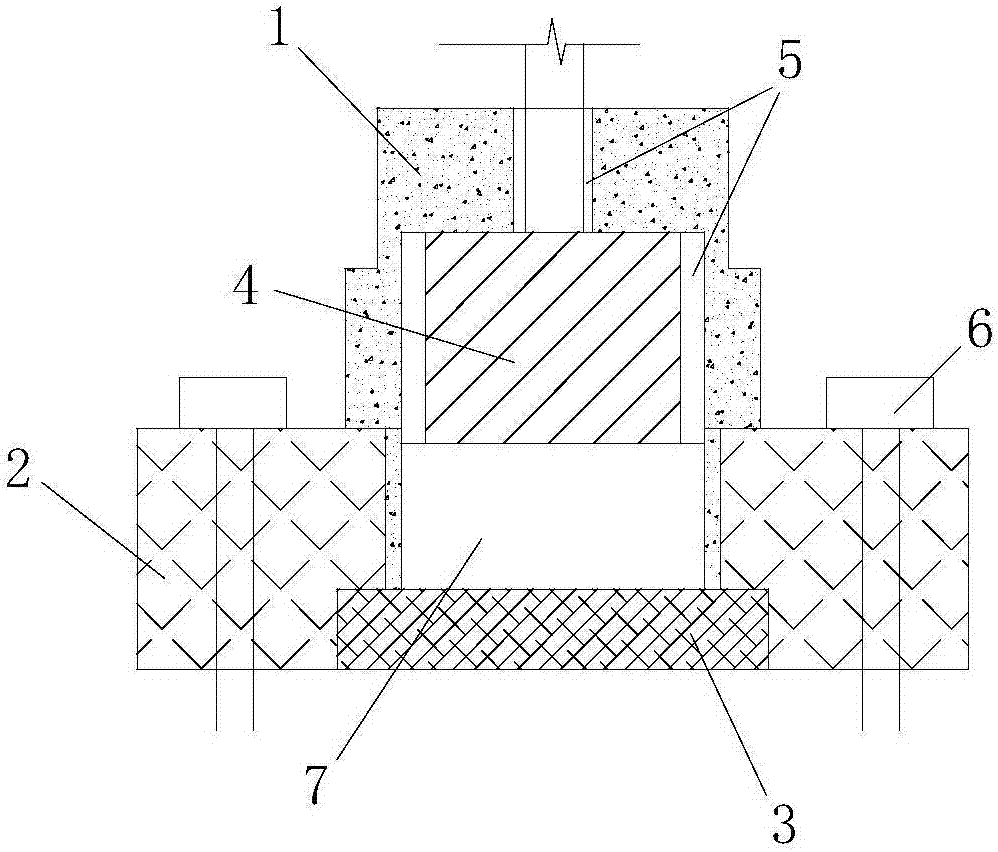

[0033] A device for testing pore water pressure, its structure is as follows figure 1 As shown, it is mainly composed of a water storage container 1, a positioning steel plate 2, a permeable stone 3 and a pore water pressure gauge 4. The middle part of the positioning steel plate 2 is provided with an opening, and the aperture is divided into two levels. The water storage container 1 is connected to the positioning steel plate 2, and is a hollow structure with a hole in the center of the interior. The pore water pressure gauge 4 is set in the water storage container 1, and the permeable stone 3 is set in the opening of the positioning steel plate 2. The upper surface and the water storage The lower surface of the container is in contact, and a water storage space 7 is formed between the permeable stone 3 and the pore water pressure gauge 4 .

[0034] The outer surface of the lower section of the water storage container 1 is provided with threads, which are matched and connect...

Embodiment 2

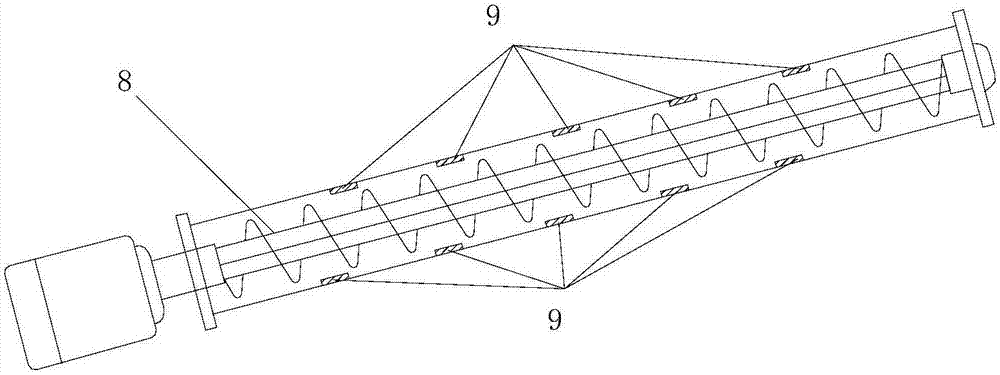

[0040] Pore Water Pressure Test of Slag in Screw Conveyor

[0041] The screw conveyor is an important component of the earth pressure balance shield, which plays a vital role in maintaining the earth pressure balance of the shield excavation face. It changes the amount of soil discharged by controlling the speed, thereby controlling the pressure of the soil chamber and realizing the balance between the pressure of the soil chamber and the pressure of the face. By fixing the present invention on the screw conveyor, the pore water pressure in the muck can be tested during the process of conveying the muck by the screw conveyor.

[0042] The details of the implementation are as follows:

[0043] Such as figure 2 As shown, five measuring points 9 are respectively selected on the upper and lower sides of the screw conveyor 8, and openings are reserved at these points when the screw conveyor is manufactured. Install the assembled manometer on each measuring point. When the sc...

Embodiment 3

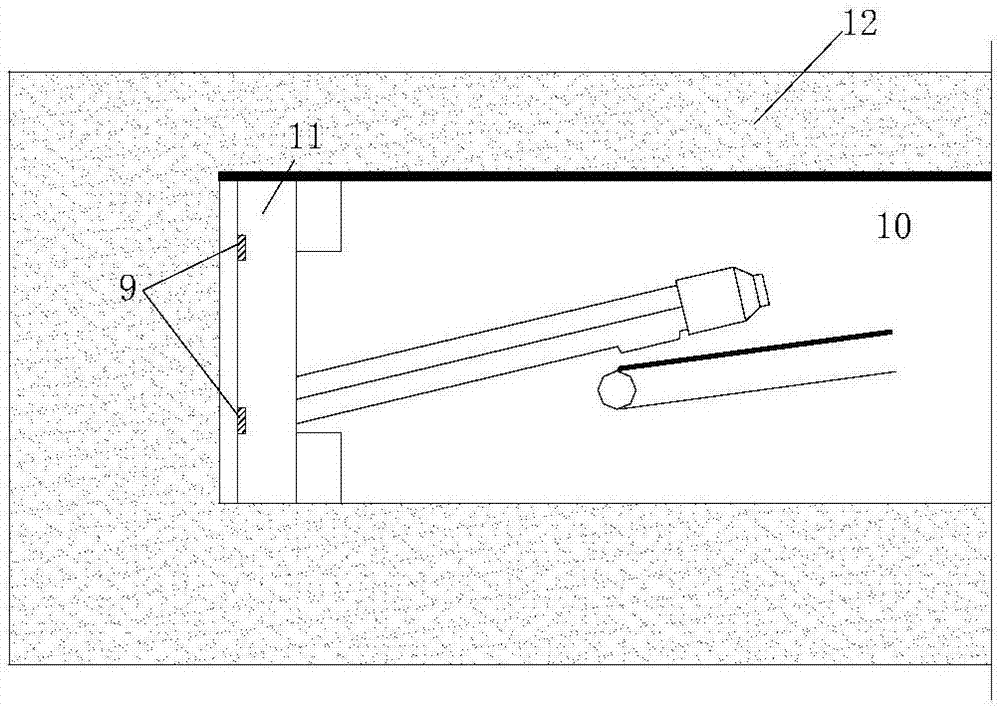

[0047] Pore water pressure test of shield machine face

[0048] For the earth pressure balance shield, the outer wall of the soil cabin is in direct contact with the soil mass of the tunnel face, and the invention can be installed on the soil bulkhead to measure the pore water pressure in the soil mass of the tunnel face.

[0049] The details of the implementation are as follows:

[0050] like image 3 As shown, the shield machine 11 is set in the soil layer 11, and a suitable location is selected as the measuring point 9 on the inner surface of the soil chamber 11 of the shield machine 10, and opening conditions are reserved at these points when the shield machine is manufactured. Install the assembled manometer on each measuring point. During the tunneling process of the shield machine, the pore water in the muck enters the water storage container from the permeable stone to realize the test of the pore water pressure. The overall size of the device and the dimensions o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com