Homogenizer for plant litter

A technology for litter and plants, which is applied in the preparation of test samples and other directions, can solve the problems of hard material, lack of plant tissue, and no consideration of cross-contamination, and achieves the effect of low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiment is described below in conjunction with accompanying drawing:

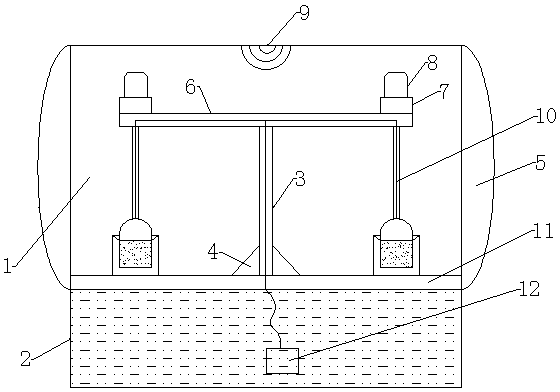

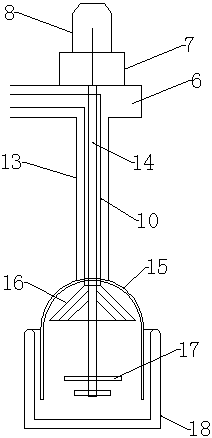

[0015] Such as figure 1 , figure 2 As shown, a homogenizing device for plant litter, which includes a sealed chamber 1, a clear water tank 2, a central main rod 3, a support plate 4, a side door 5, a balance rod 6, a reducer 7, a motor 8, and an observation lamp 9. Rubber water pipe 10, clapboard 11, cleaning pump 12, branch pipe 13, rotating shaft 14, homogenate cover 15, nozzle 16, cutting blade 17, homogenate cup 18.

[0016] The sealed chamber 1 is made of glass or stainless steel, and its shape is cylindrical, rectangular, or square, and its interior is hollow. Both sides of the sealed chamber 1 are provided with openable and airtight side doors 5, the top of the sealed chamber 1 is equipped with an observation lamp 9, and the bottom of the sealed chamber 1 is provided with a clear water pool 2 filled with clear water for cleaning utensils. The sealed chamber 1 is separated f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com