Multi-layered PCB and processing method therefor

A processing method and unique technology, applied in the direction of multi-layer circuit manufacturing, circuit board tool positioning, printed circuit components, etc., can solve problems such as low efficiency, consuming a lot of time and manpower, unable to effectively solve problems, etc., to improve product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

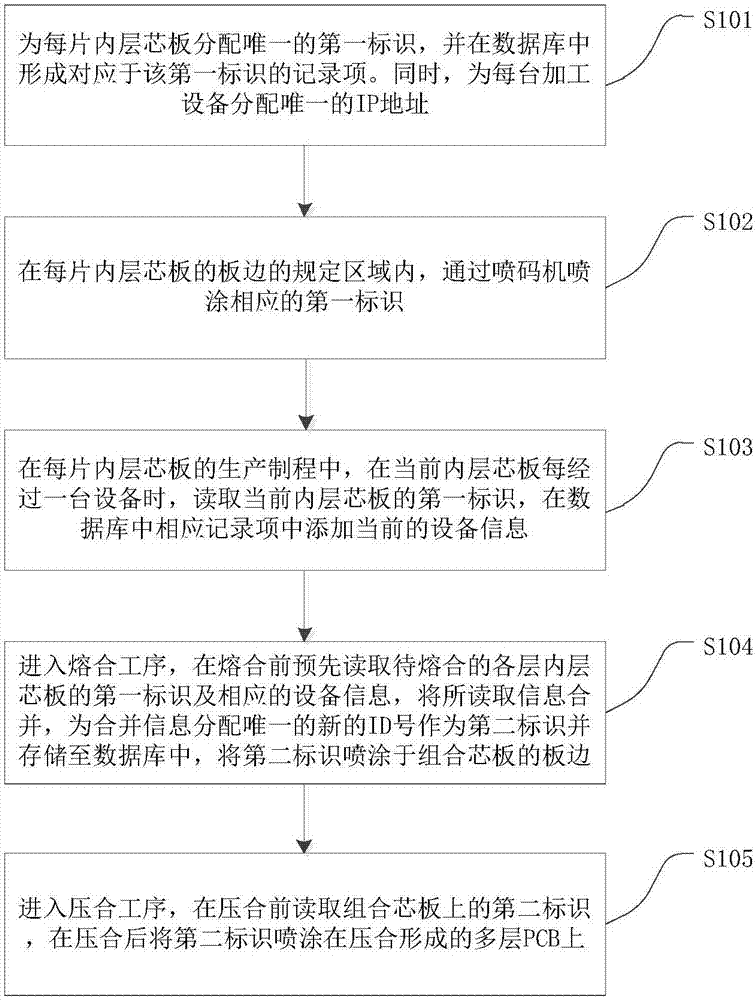

[0040] see figure 1 , a kind of processing method of multilayer PCB is provided in the present embodiment, comprises the following steps:

[0041] Step S101 , assigning a unique first identifier to each inner core board, and forming a record item corresponding to the first identifier in the database. At the same time, assign a unique IP address to each device.

[0042] In this step, a unique ID code can be assigned to each inner core board according to the work order. The ID code is used as the first identification, and its information includes model, batch number, and core board number.

[0043] Step S102 , in the specified area of the board edge of each inner layer core board, spray the corresponding first logo with the inkjet printer.

[0044] Step S103. In the production process of each inner core board, when the current inner core board passes through a piece of equipment, read the first identification of the current inner core board, and add the current ID to the cor...

Embodiment 2

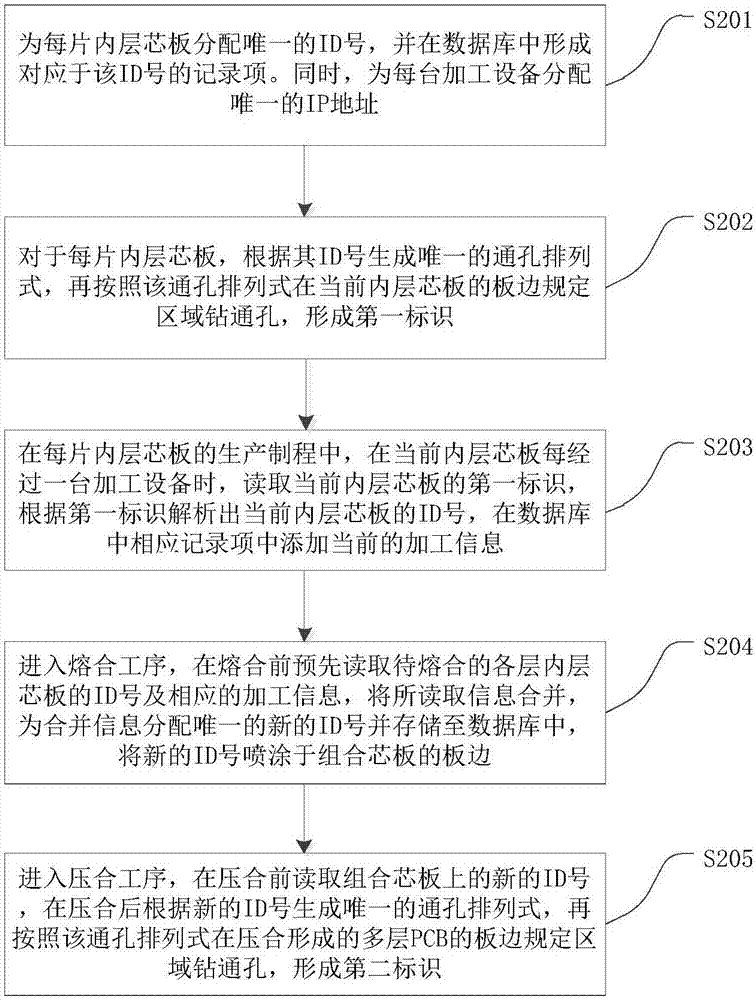

[0055] In the first embodiment, the first mark on the inner core board and the second mark on the multi-layer PCB are formed by spraying with an inkjet printer. However, in the process of production and use, the first mark and the second mark may be adversely affected by being covered due to external factors, making the mark display not clear enough to be easily read. Based on improvements.

[0056] see figure 2 , the processing method of a kind of new multi-layer PCB that present embodiment provides, comprises steps:

[0057]Step S201, assigning a unique ID code to each inner core board, and forming a record item corresponding to the ID code in the database. At the same time, assign a unique IP address to each device.

[0058] Step S202 , for each inner core board, generate a unique through hole arrangement according to its ID code, and then drill through holes in a specified area of the current inner core board according to the through hole arrangement to form a first ...

Embodiment 3

[0072] In this embodiment, a multi-layer PCB is provided, which is made by using Embodiment 1 or Embodiment 2. The outer layer forms identification information formed by spraying or drilling, and the relevant information of each inner layer can be obtained according to the identification information, so as to realize Quality traceability throughout the process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com