Peeling device for broad beans

A broad bean and rack technology, applied in the fields of application, food science, food processing, etc., can solve the problems of low efficiency of the peeling process and splitting of broad beans, and achieve the effects of enhancing practicability, ensuring integrity, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

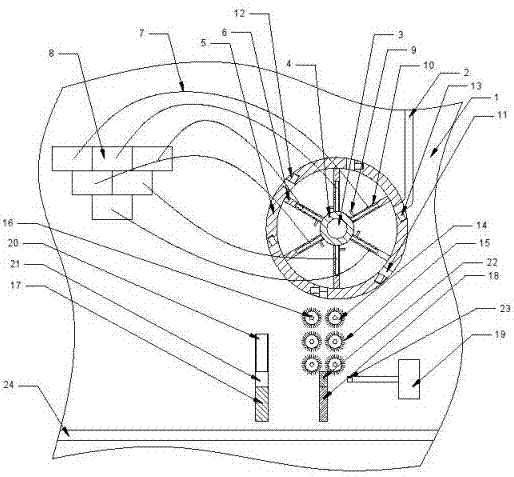

[0016] The reference signs in the drawings of the description include: frame 1, feed channel 2, rotating motor 3, inner casing 4, outer casing 5, support plate 6, steam pipe 7, steam engine 8, trigger switch 9, spray hole 10 , feeding port 11, groove 12, baffle plate 13, round shaft 14, bristles 15, auxiliary motor 16, first pillar 17, second pillar 18, cylinder 19, storage tank 20, through hole 21, clamping arm 22 , sponge layer 23, transmission belt 24.

[0017] The embodiment is basically as attached figure 1 Shown: the broad bean peeling device includes a frame 1, and the frame 1 is sequentially provided with a feed channel 2, a rotating mechanism, a peeling mechanism and a casing mechanism from top to bottom; the rotating mechanism includes a rotating motor 3, an inner sleeve The tube 4 and the outer sleeve 5, the rotating shaft of the rotating motor 3 are affixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com