A Lithographic Approach to Mitigate Wafer Edge Defocus

An edge-to-wafer technology, applied in the field of lithography to reduce defocusing at the edge of the wafer, can solve problems such as defocusing errors, reduce variance, improve lithography accuracy, and reduce defocusing at the edge of the wafer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0026] The present invention provides a kind of lithography method that slows down wafer edge defocusing, comprises the following steps:

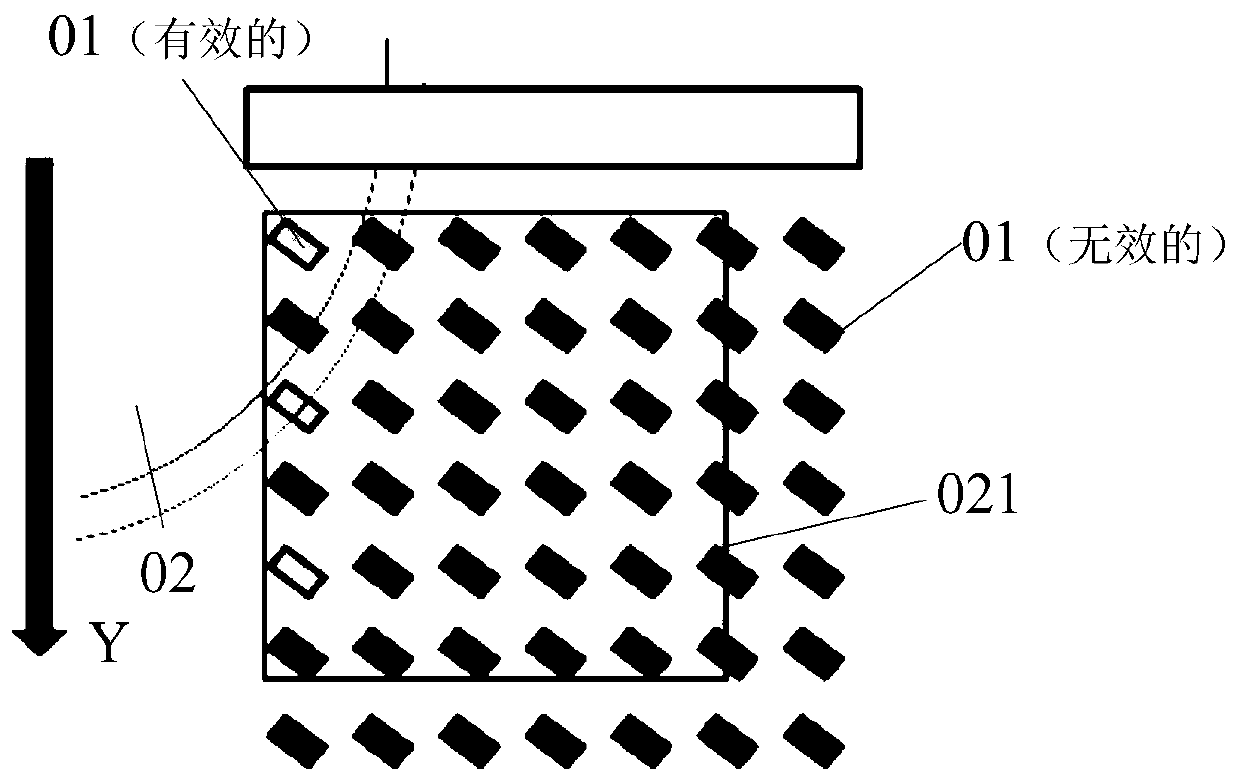

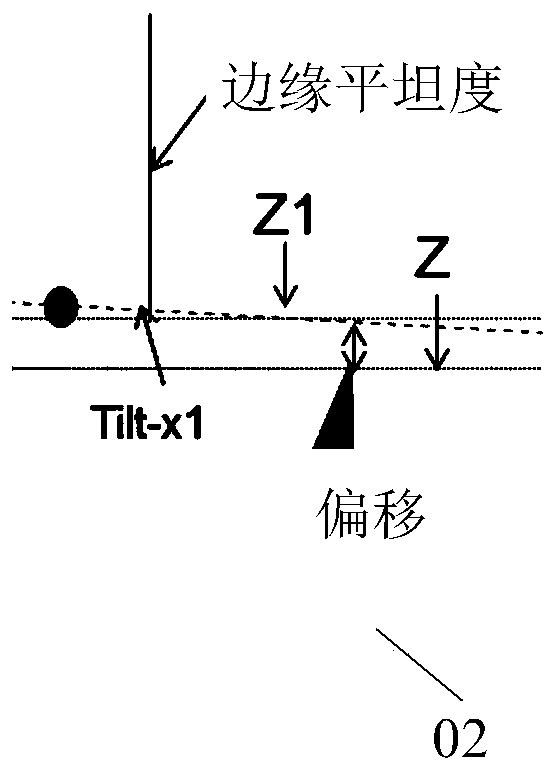

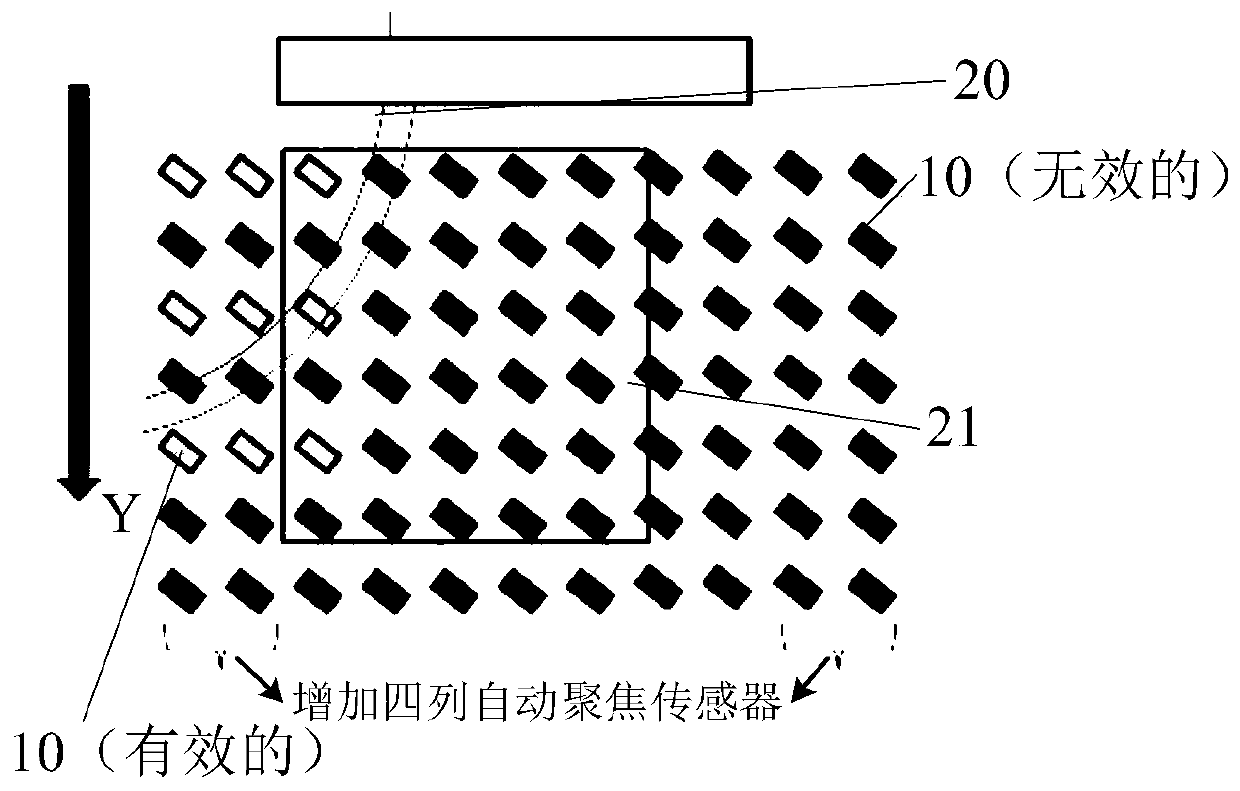

[0027] Step 1: Provide a lithography machine equipped with an autofocus sensor 10. The scanning direction of the lithography machine during lithography is defined as the scanning direction, also defined as the Y direction, and the direction perpendicular to the scanning direction on the horizontal plane is defined as the non-scanning direction , is also defined as the X direction, the arrangement of the autofocus sensors 10 along the non-scanning direction is defined as a row, and the arrangement along the scanning direction is defined as a row, compared with the autofocus sensor in the existing phot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com