A method and application of femtosecond laser direct writing processing with continuously adjustable depth near 4π solid angle

A technology of femtosecond laser and solid angle, applied in metal processing equipment, laser welding equipment, manufacturing tools, etc., to achieve the effect of reducing defocus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

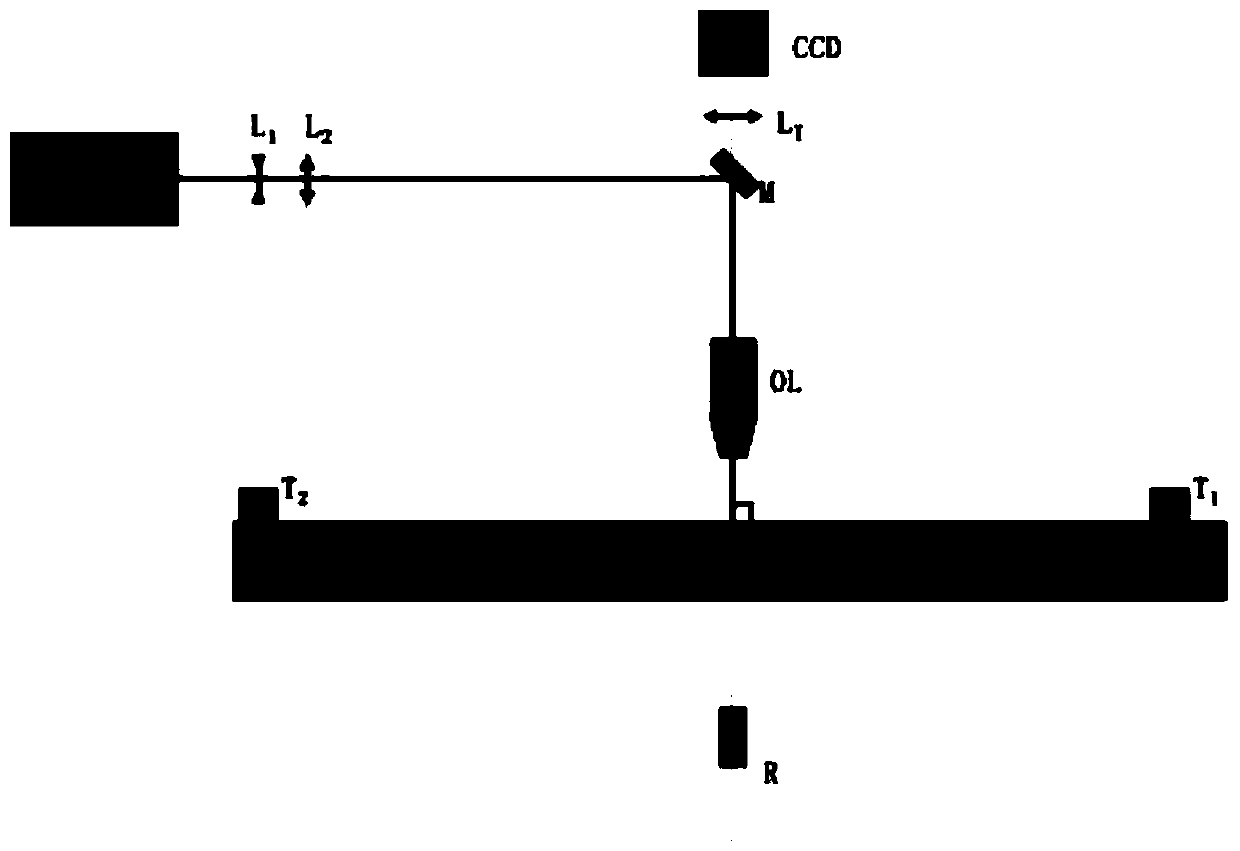

Embodiment 1

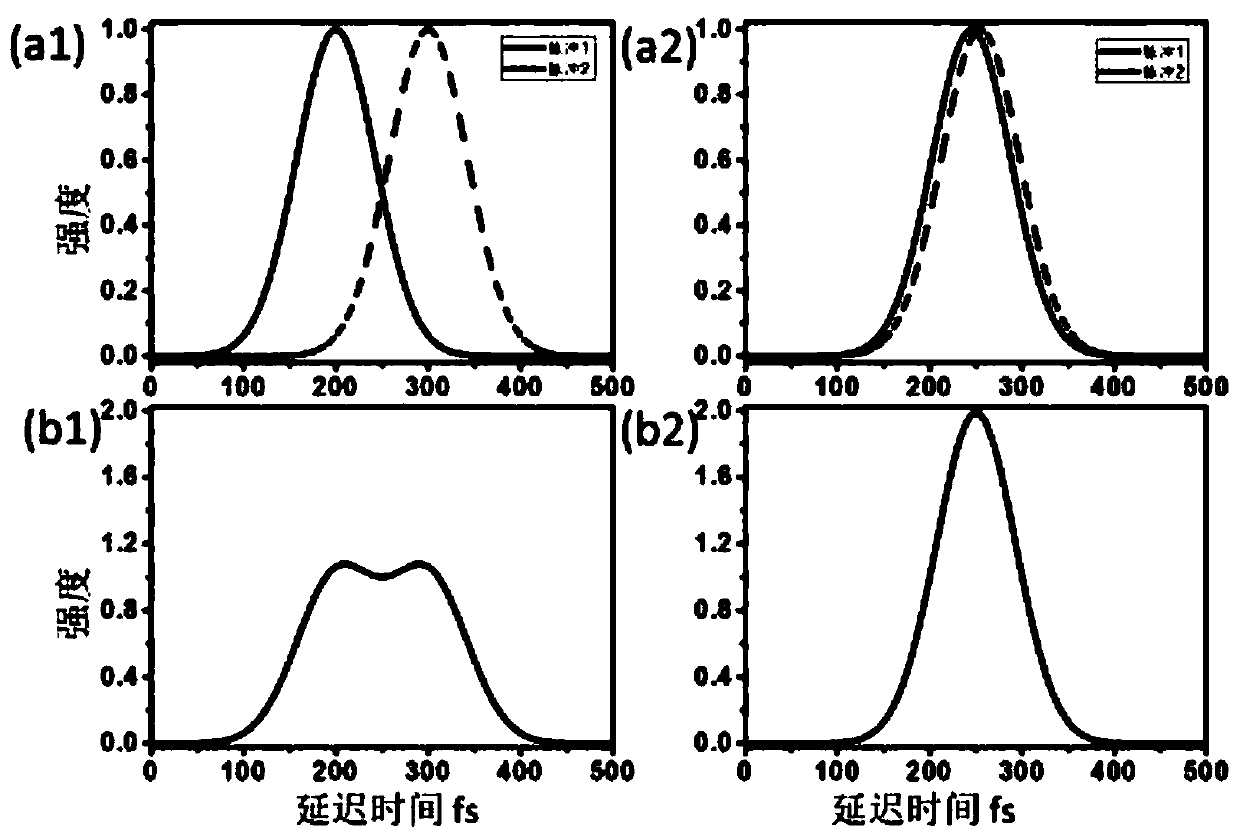

[0034] Two-photon excitation is achieved by adjusting the time-domain synchronization of sub-beam femtosecond laser pulses.

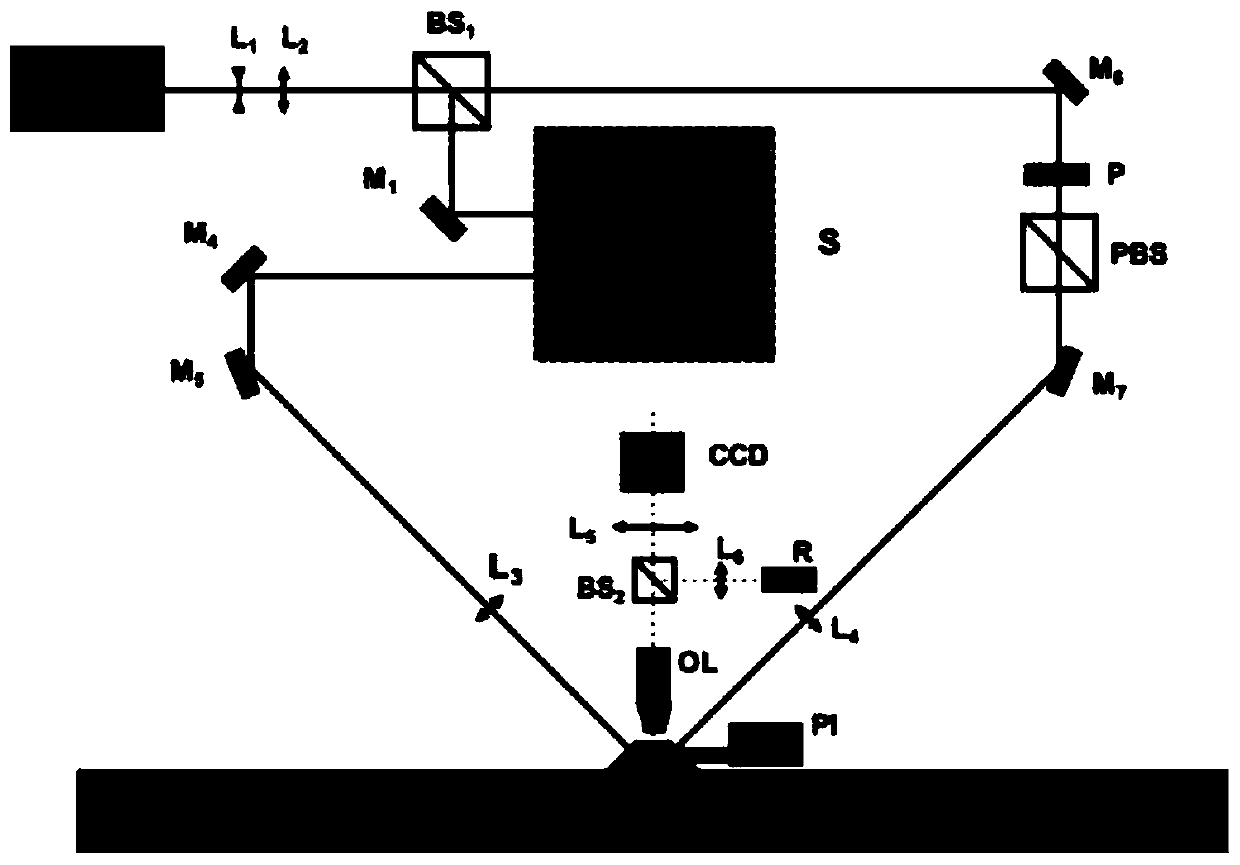

[0035] The method of using two-photon excitation to "combine" energy can also provide the energy required for material modification. By adding a glass quadrangular mirror QL and a refractive index matching liquid on the surface of the sample, the two facets perpendicular to each other of the laser vertical incidence QL are adjusted, so that the two femtosecond laser beams do not refract when they enter the sample through the QL, thus effectively The defocusing is weakened and the near-spherical two-photon excitation focal spot with a solid angle of nearly 4π is obtained, which solves the serious defocusing of the single-beam femtosecond laser in direct writing processing with a large buried depth. In order to ensure that the energy of the two photons can be effectively superimposed, the femtosecond laser needs to be divided into beams and adjusted seque...

Embodiment 2

[0046] Fabrication of buried depth-varying glass waveguide devices using a two-photon excitation focal spot with nearly 4π solid angle.

[0047] By synchronously controlling the movement of the sample stage and the piezoelectric platform up and down, the continuous adjustment of the depth of the two-photon excitation focal spot inside the material to be processed can be realized, so that the direct writing processing of the three-dimensional waveguide structure with a large buried depth can be realized.

[0048] Three-dimensional embedded structure processing using two-photon excitation focal spot with nearly 4π solid angle:

[0049] (1), pulse time synchronous rough adjustment: with embodiment 1,

[0050] (2), pulse space synchronization adjustment: same as embodiment 1.

[0051] (3), synchronous fine-tuning of pulse time: same as embodiment 1.

[0052] (4) Three-dimensional embedded structure direct writing: the material to be processed is glass, and the embedding depth to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com