Method for carrying out nearly 4pi solid angle femtosecond laser direct writing processing through triangular prism and application thereof

A technology of femtosecond laser and triangular prism, applied in metal processing equipment, laser welding equipment, manufacturing tools, etc., can solve the problems of elongated laser focus and different light guiding characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

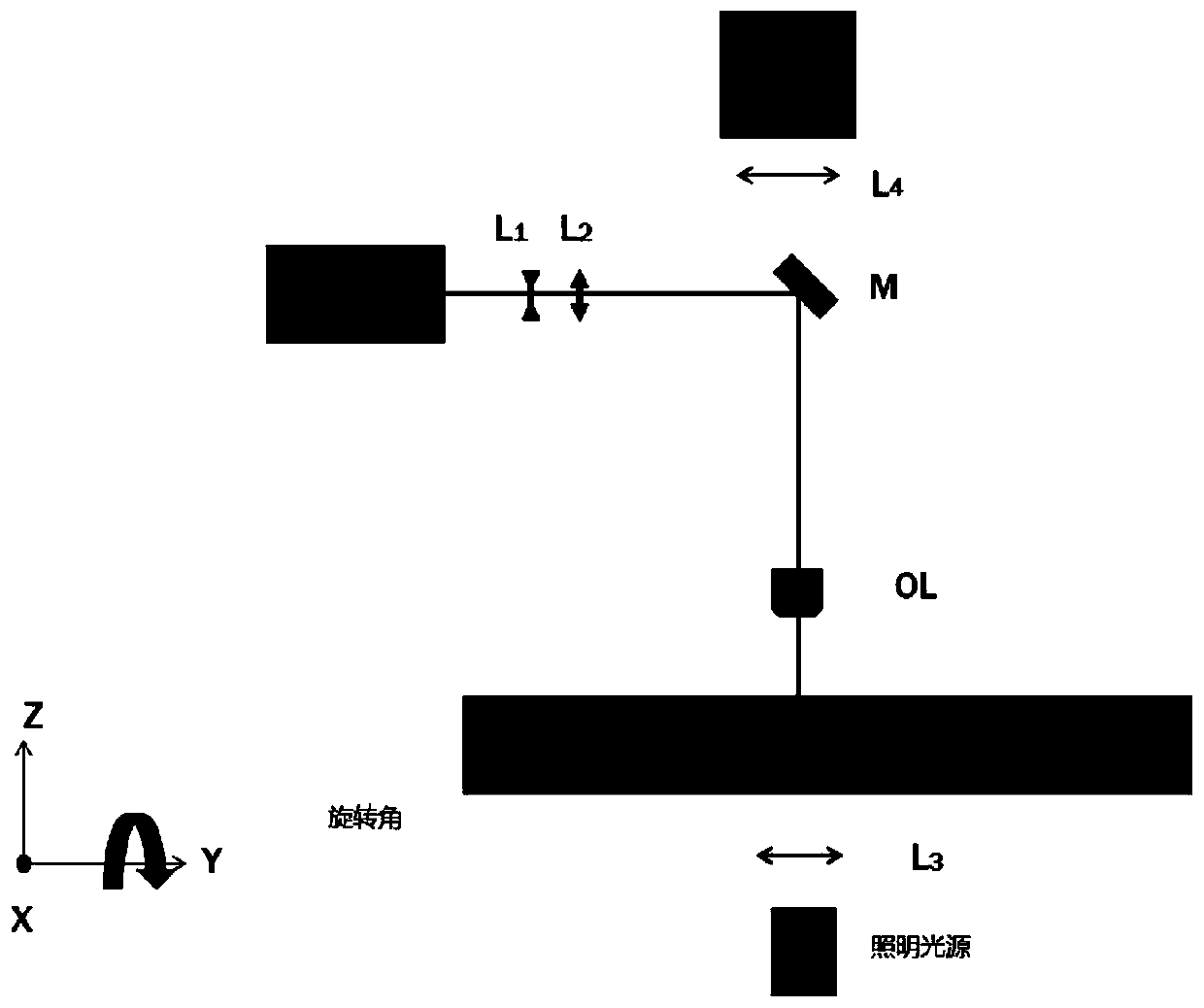

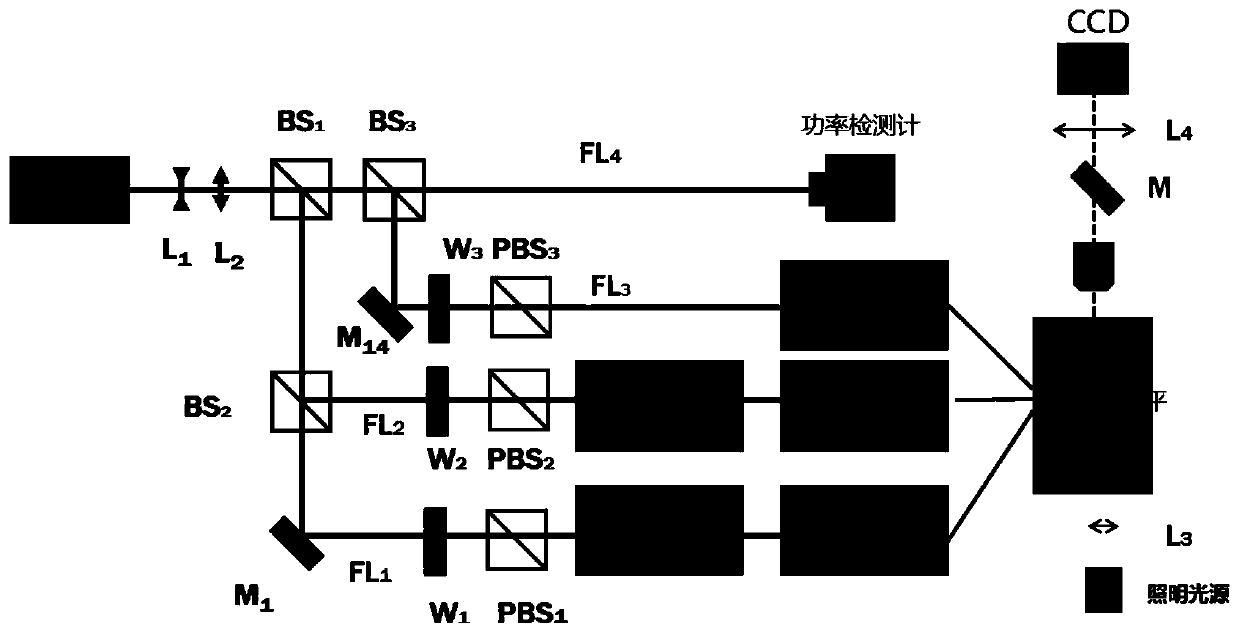

[0048] Embodiment 1 A three-photon excitation focal spot is formed by using a triangular frustum prism to make three sub-beams of femtosecond laser beams orthogonally.

[0049] The single-beam processing method is replaced by the method of "combining" energy with three-photon excitation, and the energy required to modify the processed material is provided in this way. A triangular prism and a refractive index matching liquid are added on the surface of the sample, so that the laser is normally incident on the three sides of the triangular prism, so that the laser beam is not refracted when it is incident on the triangular prism and inside the sample, and the three sub-beams The femtosecond laser is orthogonally converged to form a near-spherical focus with a solid angle of nearly 4π. Compared with the severe defocus of a single femtosecond laser in direct writing processing with a large buried depth, this method effectively overcomes the single-beam Defocus problem of laser in...

Embodiment 2

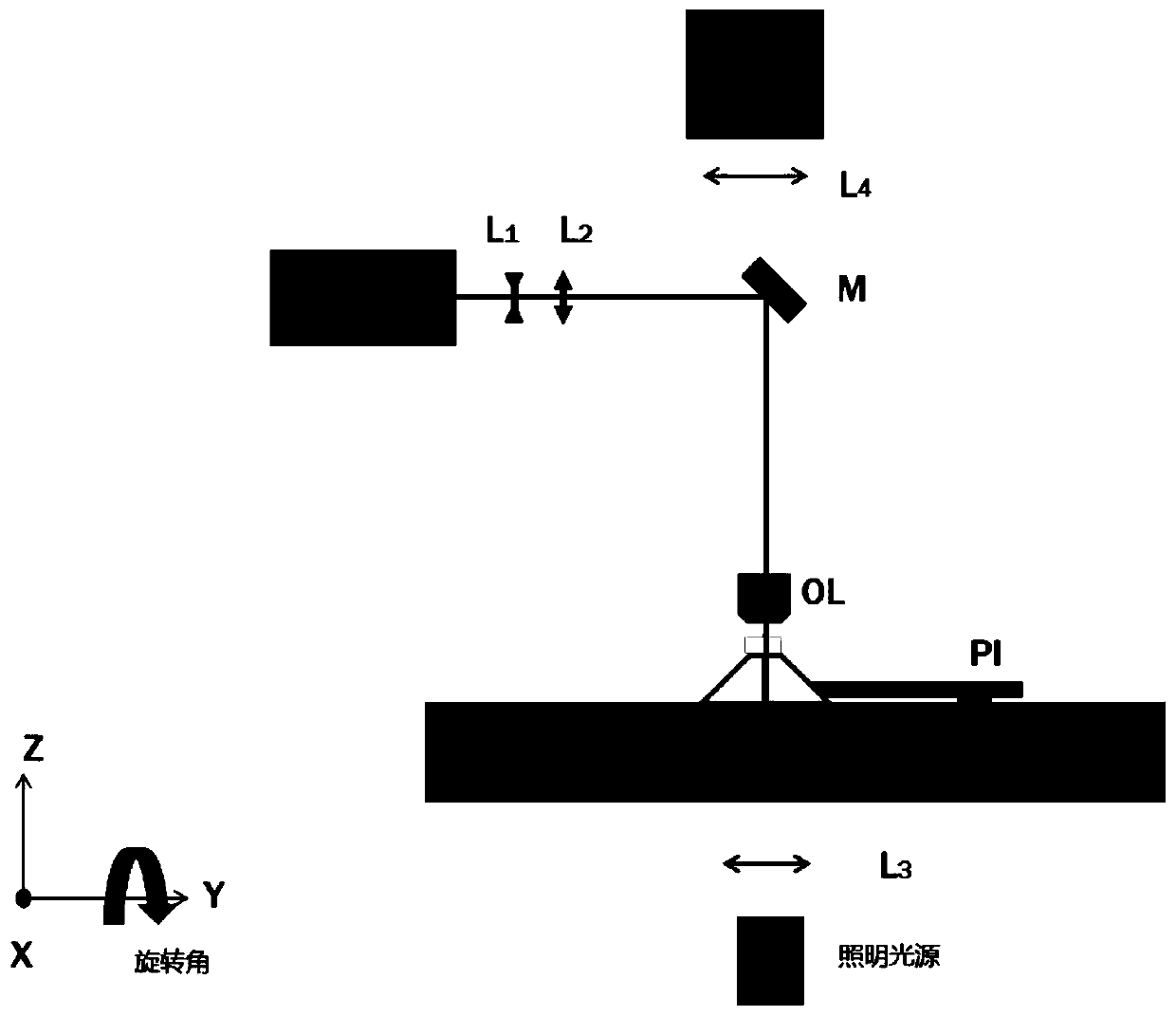

[0065] Example 2 uses a three-photon excitation focus with a solid angle of nearly 4π to implement a three-dimensional embedded waveguide quantum device.

[0066] By adjusting the time synchronization of sub-beam femtosecond laser pulses and using space synchronization, the three sub-beam femtosecond laser beams are incident on the three sides of the triangular prism, avoiding internal damage caused by the refraction phenomenon caused by light incident from different media. The problem of defocusing, and the three-photon excitation focus with a solid angle of nearly 4π can be obtained deep inside the material, and its energy distribution has a near-spherical characteristic, which solves the problem of internal defocusing in laser processing.

[0067] Near 4π solid angle femtosecond laser direct writing processing of three-dimensional embedded structures by using triangular prism assisted three-photon excitation:

[0068] (1) Leveling of the sample stage and the triangular pris...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com