Tubing string stability and safety analysis-based downhole perforation test tool string optimization method

An optimization method and technology of test tools, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve the problems of large damage and failure of the pipe string, less dynamic behavior, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0119] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

[0120] A downhole perforation test tool string optimization method based on tubing string stability and safety analysis, which includes the following steps:

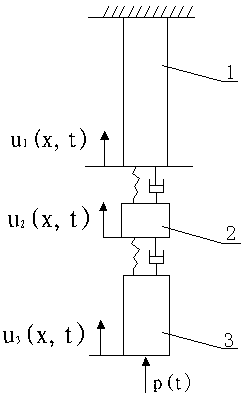

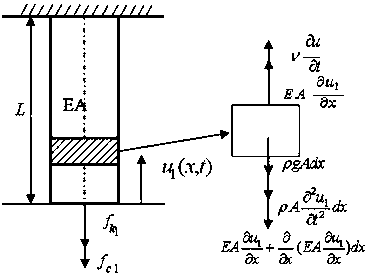

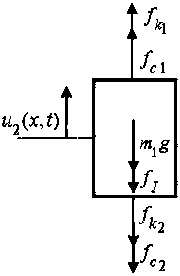

[0121] S1. According to the structural analysis of the downhole perforating tool and the analysis of the perforating process, the following assumptions are made: assuming that the materials of the tubing string and the perforating gun are uniform and isotropic; assuming that the shock absorber is a mass-spring-damping system, ignoring shock absorption The geometric shape of the packer and the inhomogeneity of mass distribution; the relative displacement between the packer and the tubing string is not considered, and it is regarded as a fixed support; the structural damping of the perforating string is ignored, and only the shock absorber and liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com