Motor with brake in rear end cap

A technology of rear end cover and brake, which is applied in the direction of controlling mechanical energy, electrical components, electromechanical devices, etc. It can solve the problems of large volume ratio, influence of the motor body, and powder generated by the friction plate, so as to meet the requirements of lightweight and reduce the weight of the motor , Compact structure and simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

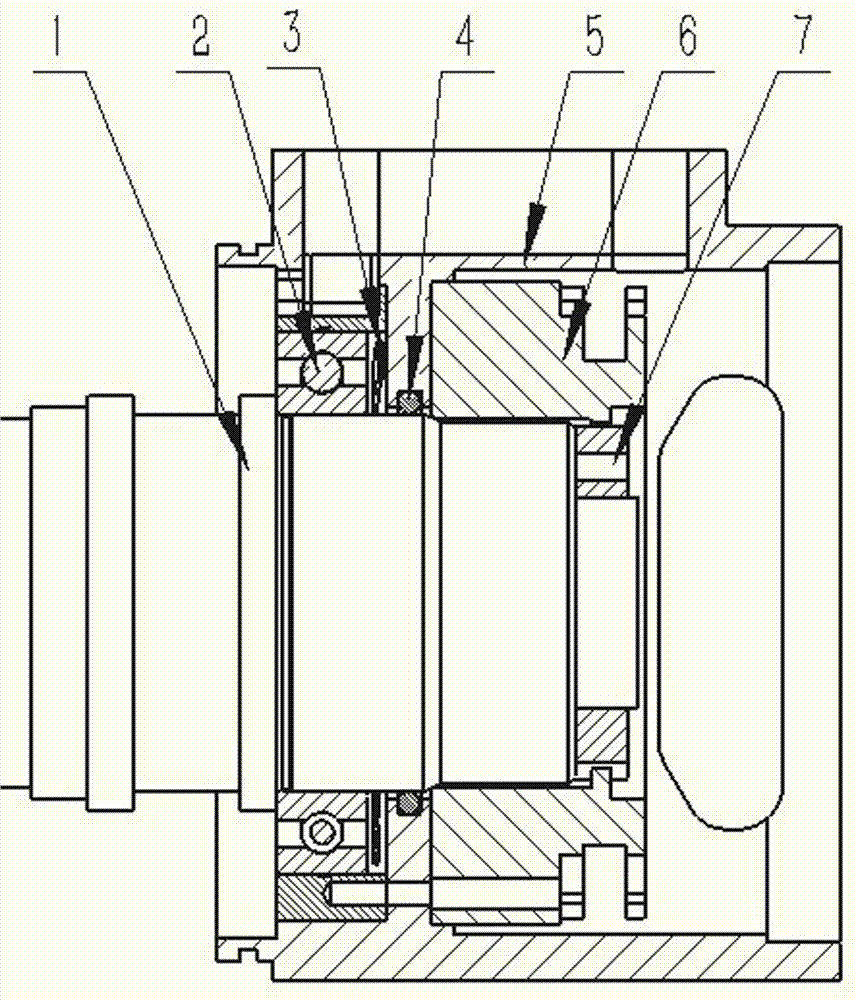

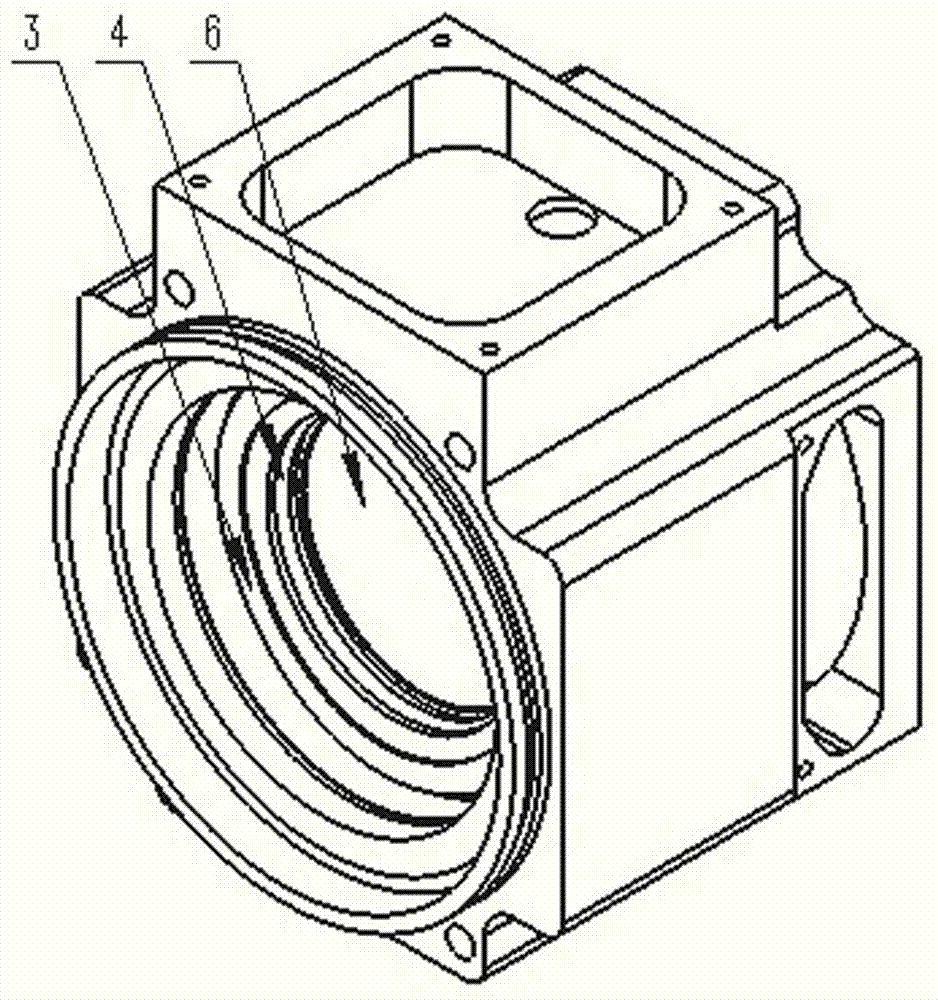

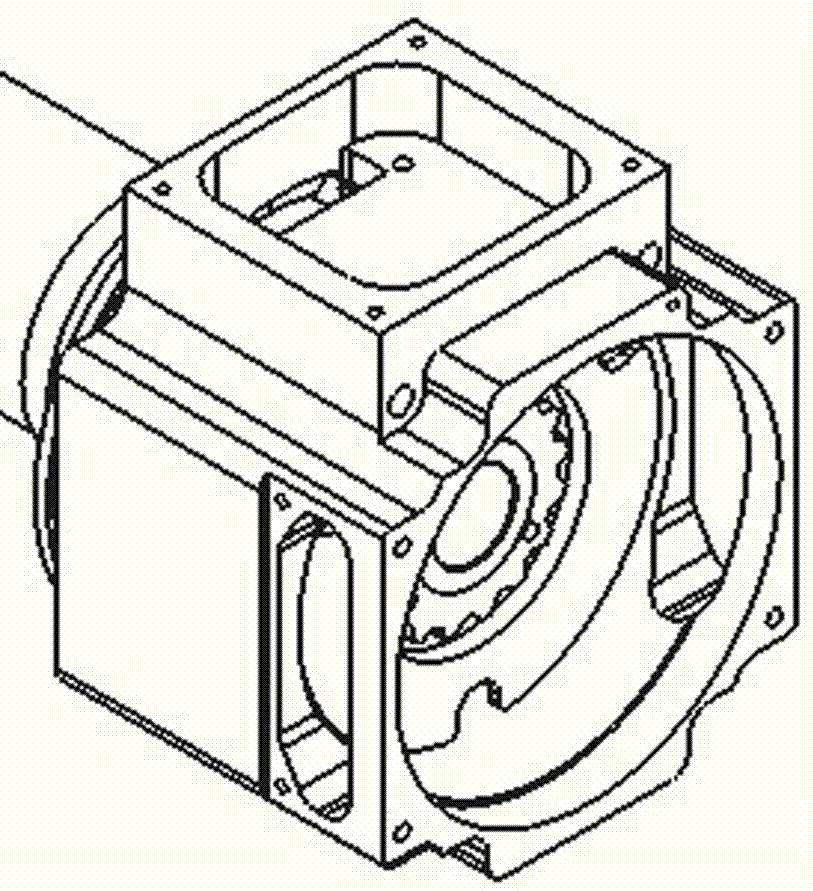

[0017] A motor with a brake in the rear end cover, the structure of the rear end of the shaft is as follows figure 1 shown. The rotating shaft 1 is assembled with the bearing 2 to ensure that the rotating shaft 1 and the inner ring of the bearing 2 are tightly fitted. At the same time, the brake rotor 7 is assembled to the rear end of the rotating shaft 1, such as Figure 4 shown.

[0018] Such as figure 1 , 2 , As shown in 3, the rear end cover 5 is divided into a bearing chamber and a brake chamber. There is a rotating shaft hole between the bearing chamber and the brake chamber, and a sealing ring groove is formed on the inner circumference of the rotating shaft hole, and a sealing ring 4 is arranged in the sealing ring groove. The rear end of the rotating shaft 1 passes through the rotating shaft hole and is inserted into the brake chamber of the rear end cover, and the sealing ring 4 seals between the rotating shaft 1 and the rotating shaft hole. The rear end cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com