Tippy tea processing technology

A processing technology, Maofeng's technology, applied in the field of Maofeng tea processing technology, can solve the problems of reducing the quality of finished tea, and achieve the effect of improving quality, increasing stroke, and increasing friction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] The processing technology of the present embodiment includes:

[0023] Picking: Before and after the Qingming Festival, pick one bud and one leaf tea, keep the buds and leaves fresh, complete and even, and do not pick rain leaves, dew leaves, purple buds and leaves, leaves caused by diseases and insect pests;

[0024] Cooling: place the picked tea leaves in a bamboo tray and put them in a cool and ventilated place. The leaf thickness is 2-3cm, which is 2cm in this embodiment, and the spreading time is 6 hours;

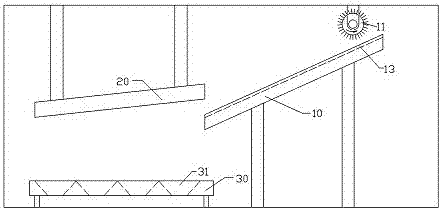

[0025] Sorting: Sorting equipment such as figure 1 As shown, a runner 11 is arranged above the plastic plate 10 arranged obliquely, a slideway 13 is provided on the plastic plate 10, and the transmission plate 20 is arranged obliquely, the inclination angle of the transmission plate 20 is smaller than the plastic plate 10, and a A screening plate 30, the screening plate 30 is provided with a flared sieve hole 31;

[0026] Sorting-S1: Pour the cooled tea leaves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com