A kind of deacetylation hydrogen catalyst and its preparation method and application

A catalyst and auxiliary technology, applied in the field of alkyne hydrogenation catalytic removal, can solve the problems of difficult reaction temperature and pressure control, short catalyst life, low ethylene selectivity, etc., and achieve wide reaction control, high selectivity, and olefin selectivity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

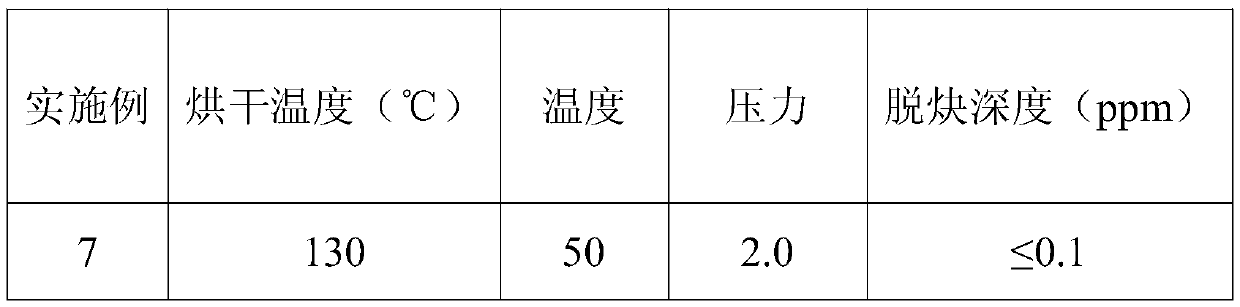

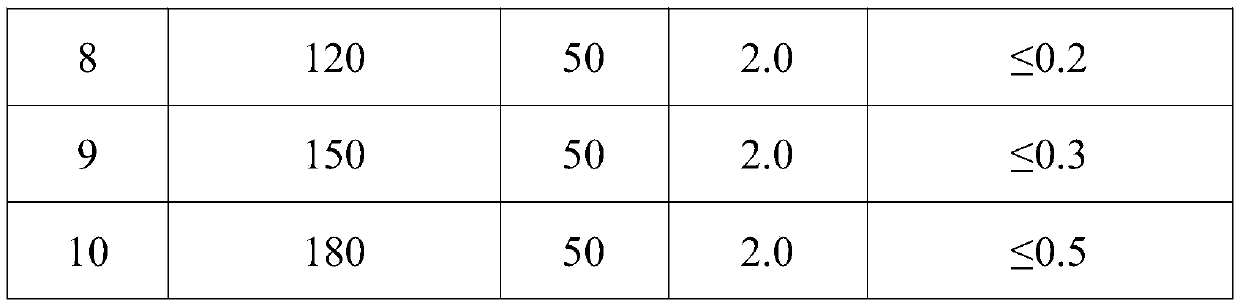

[0028] Weigh PdCl in proportion 2 , Ni(NO 3 ) 2 , Mn(NO 3 ) 2 and Cu(NO 3 ) 2 , the proportioning ratio is shown in Table 1. Dissolve the above components and make them fully mixed in the alcohol (concentration 80%) solution, spray on the supporting carrier γ-Al 2 o 3 The surface of the ball is burned to fix the active components, and the pre-configured hydrazine hydrate reducing solution is used for reduction treatment for 8-12 hours, and the impurity components are eluted with deionized water for 4-12 times, and finally dried at 130 ° C to obtain the catalyst for use .

[0029] Take 50ml of catalyst and put them into a stainless steel reactor of Φ30mm×2.5mm×250mm, feed the raw material gas at 50°C and a pressure of 2.0MPa, and the gas phase space velocity of the raw material gas is 3000h -1 , the inlet acetylene content is 0.50%, and the deacetylation depth is ≤0.1ppm.

Embodiment 2~4

[0031] The preparation method and testing method are the same as in Example 1, the difference is only in the composition of the catalyst, see Table 1 for details.

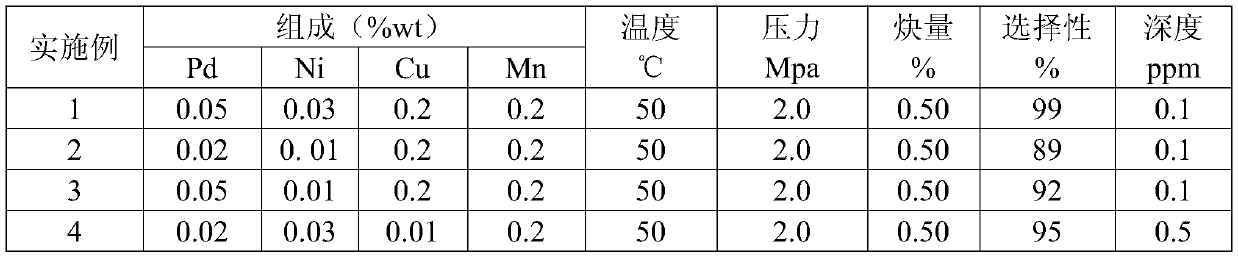

[0032] Table 1 Embodiment 1-4 Composition and evaluation results of the deykyne hydrogenation catalyst

[0033]

Embodiment 5

[0035] Weigh PdCl 2 , Ni(NO 3 ) 2 , Mn(NO 3 ) 2 and Cu(NO 3 ) 2 , the proportioning is (wt) 0.03%, 0.03%, 0.2% and 0.2% respectively, PdCl 2 Add hydrochloric acid to dissolve into a palladium chloride solution, fully and evenly dissolve it and the remaining components in the food-grade alcohol (concentration 80%) solution, and spray the mixed solution on the γ-Al 2 o 3 The surface of the ball is then burned to fix the active components, and the pre-configured hydrazine hydrate reducing solution is used for reduction treatment for 8-12 hours, and the impurity components are eluted with deionized water for 4-12 times, and finally dried at 130°C for use. Take 50ml of catalyst and put them into a stainless steel reactor of Φ30mm×2.5mm×250mm, feed the raw material gas under the conditions of 80°C and pressure 2.0MPa, and the gas phase space velocity of the raw material is 3000h -1 , the inlet acetylene content is 0.50%, and the deacetylation depth is ≤0.1ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com