Electric field for plasma or electrostatic purifier or dust removing equipment

A kind of dust removal equipment, electrostatic technology, applied in the field of electric field of core components, can solve problems such as inconsistent exhaust gas composition, increased resistance, unstable air flow, etc., to achieve the effect of reducing raw material consumption, reducing overall size, and ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

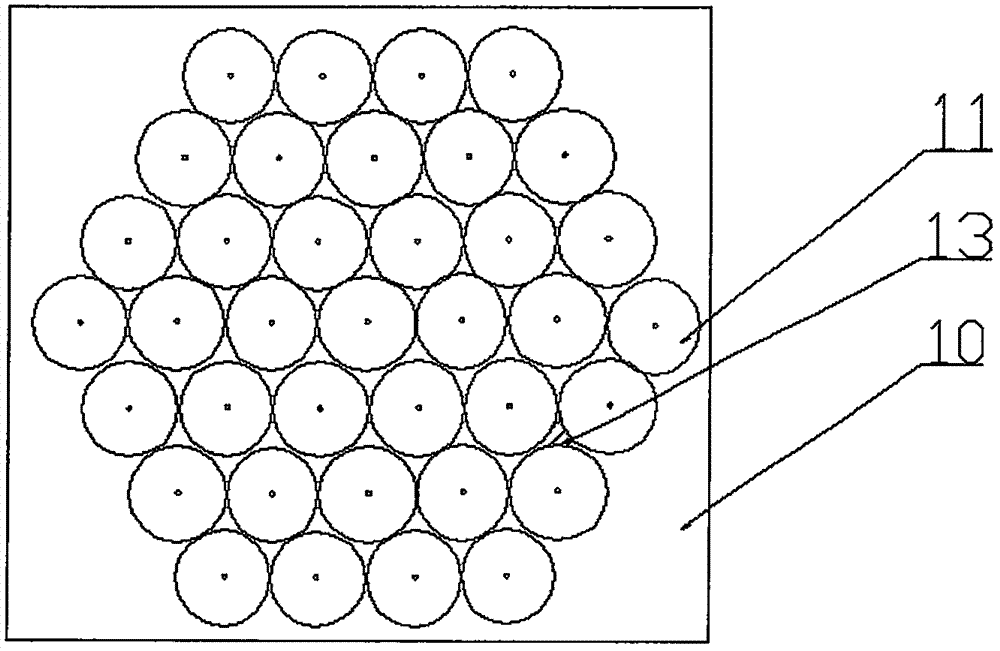

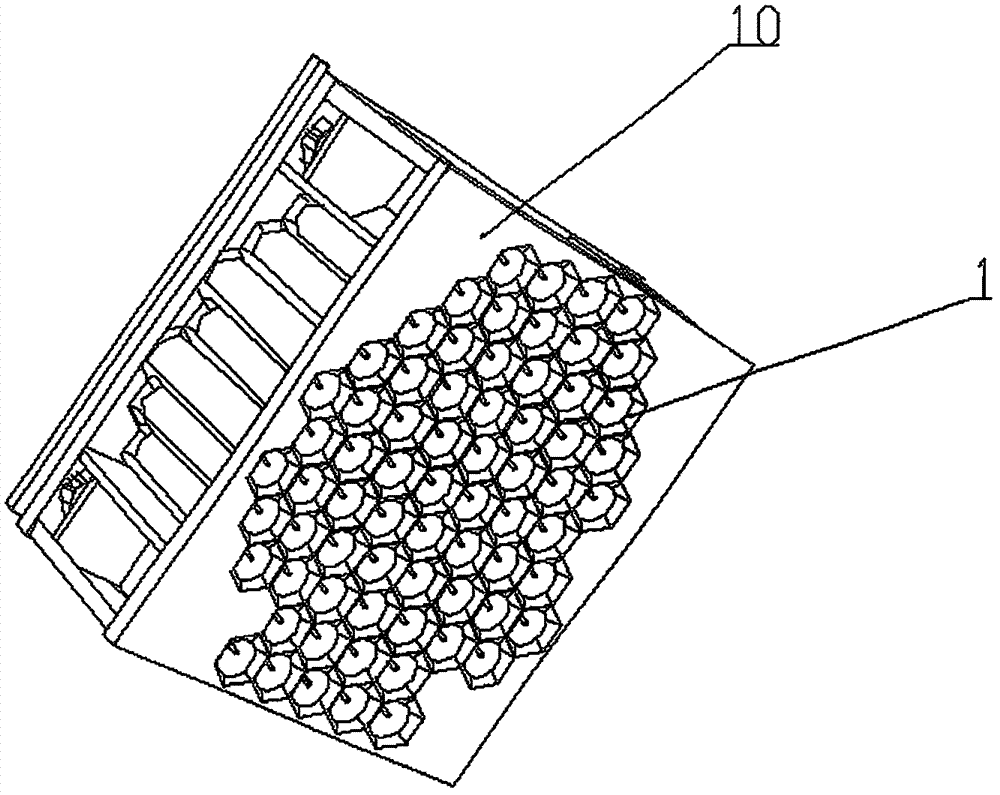

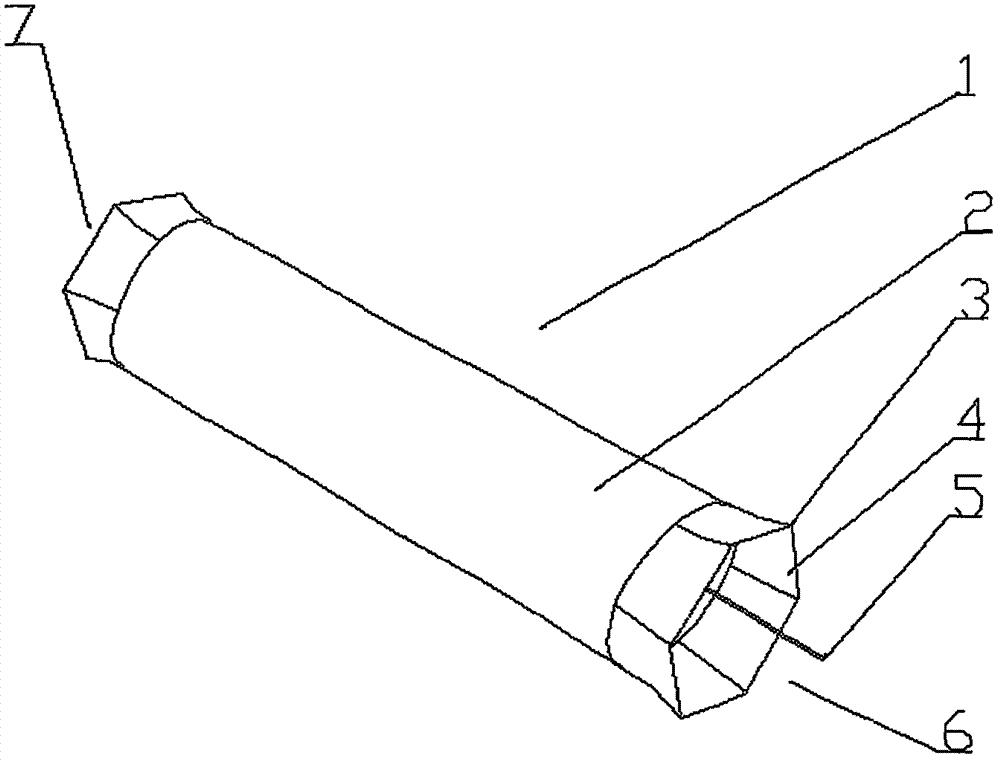

[0021] Embodiment 1, a kind of electric field that is used for plasma or electrostatic purifier and dedusting equipment, it consists of a frame, a fixed panel (10) is respectively spliced on both sides of the frame, and a cathode conductive frame is fixed on both sides of the fixed panel (10), There is a hole in the middle of the fixed panel (10), and four special-shaped tubes (1) are socketed in the hole in three rows, and each row is composed of one, two, and one number. The special-shaped tubes (1) are arranged in sequence without blind spots (13 ), the middle part of the special-shaped pipe is a working section, and the inner hollow circular pipe (2), the two ends of the circular pipe (2) are connected to the airflow guide section, and the airflow guide section is provided with six arc-shaped side plates (4), and the side plate ( 4) One end is connected to the cylinder (2), and the other end of the side plate (4) is sequentially spliced into a regular hexagonal port (3)...

Embodiment 2

[0022] Embodiment 2, a kind of electric field that is used for plasma or electrostatic purifier and dedusting equipment, it consists of a frame, a fixed panel (10) is respectively spliced on both sides of the frame, and a cathode conductive frame is fixed on both sides of the fixed panel (10), There is a hole in the middle of the fixed panel (10), and 19 special-shaped tubes (1) are arranged in five rows in the hole. (1) There is no blind area (13) at the splicing in sequence, the middle part of the special-shaped tube is the working section, and the inner hollow round tube (2), the two ends of the round tube (2) are connected to the airflow guide section, and the airflow guide section is provided with six The arc-shaped side plate (4), one end of the side plate (4) is connected to the cylinder (2), the other end of the side plate (4) is sequentially spliced into a regular hexagonal port (3), and the side plate (4) is connected to the cylinder (2 ) one end is one-sixth of ...

Embodiment 3

[0023] Embodiment 3, a kind of electric field that is used for plasma or electrostatic purifier and dedusting equipment, it consists of a frame, a fixed panel (10) is spliced on both sides of the frame, and a cathode conductive frame is fixed on both sides of the fixed panel (10), There is a hole in the middle of the fixed panel (10), and thirty-seven special-shaped tubes (1) are arranged in seven rows in the hole, and each row is composed of four, five, six, seven, six, five, four numbers of electric fields, and the special-shaped tubes (1) There is no blind area (13) at the splicing in sequence, the middle part of the special-shaped tube is the working section, and the inner hollow round tube (2), the two ends of the round tube (2) are connected to the airflow guide section, and the airflow guide section is provided with six The arc-shaped side plate (4), one end of the side plate (4) is connected to the cylinder (2), the other end of the side plate (4) is sequentially spli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com