Shallow water mooring system and barge

A mooring system, shallow water technology, applied to barges/flat-bottomed boats, ship components, ship construction, etc., can solve the problems of high cost and low effectiveness of catenary mooring systems, and achieve improved service life, simple structure, The effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

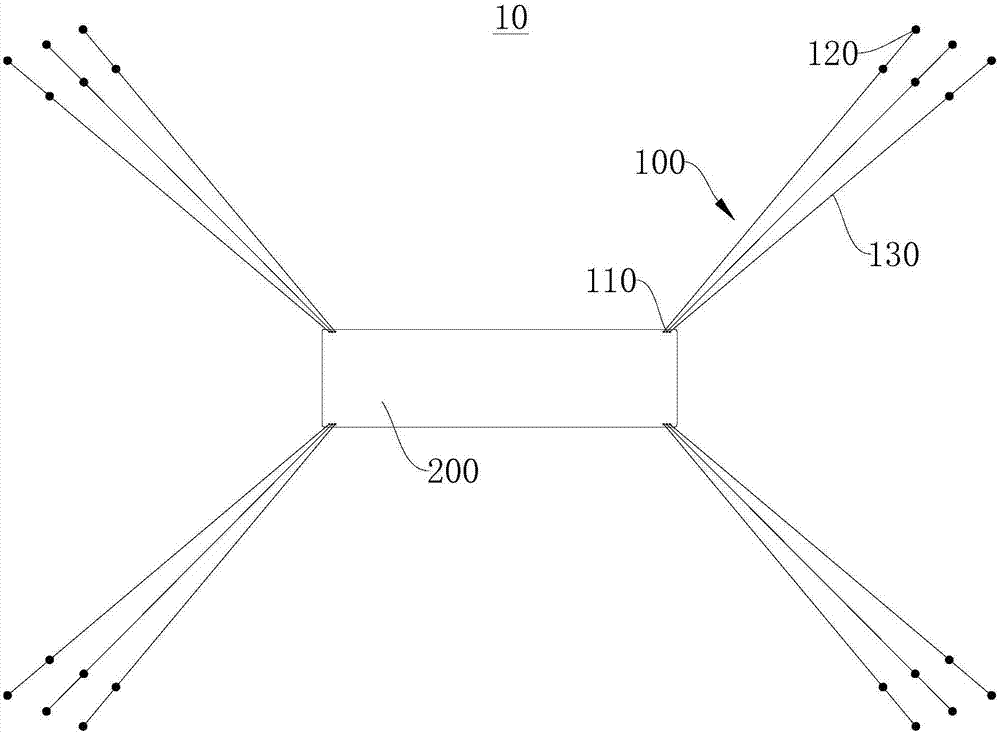

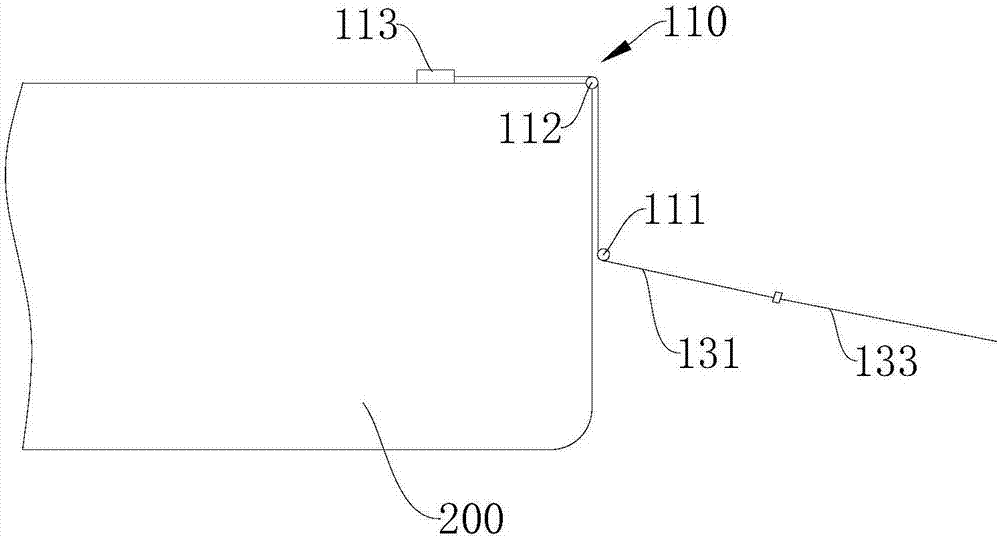

[0038] see Figure 1 to Figure 3 , the present embodiment provides a barge 10, which is simple in structure and easy to use. At the same time, it can ensure greater axial rigidity and has a long service life.

[0039] The barge 10 provided in this embodiment includes a shallow water mooring system 100 and a barge body 200 . That is, the shallow water mooring system 100 is used to moor the barge body 200 .

[0040] In this embodiment, the number of shallow water mooring systems 100 is 12, which are equally divided into four groups and arranged at four corners of the barge body 200 . Of course, it is not limited thereto. In other embodiments of the present invention, the number of shallow water mooring systems 100 may also be other numbers, such as 16.

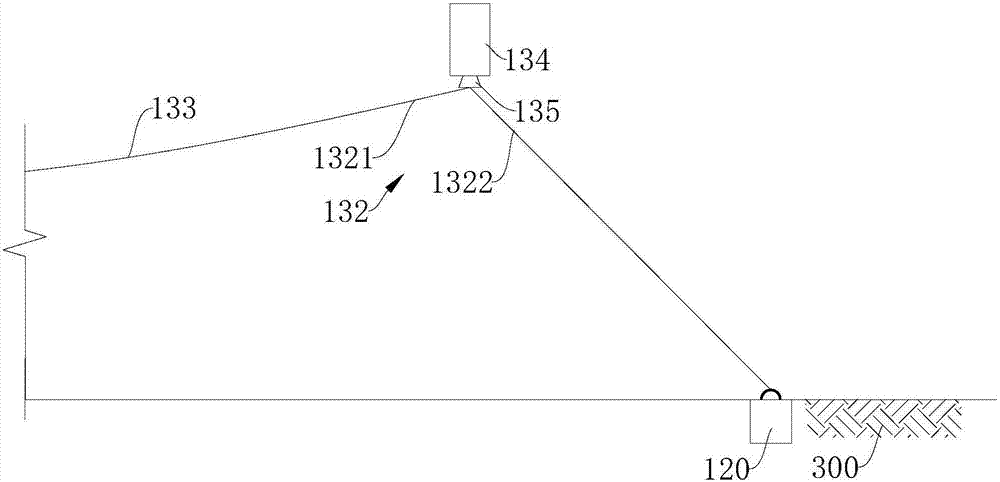

[0041] The shallow water mooring system 100 provided in this embodiment includes a first connection component 110 , a second connection component 120 and a mooring line 130 . One end of the mooring cable 130 is fixedly conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com