Fast airship capsule inflating system and method

An inflation system and capsule technology, applied in the field of aircraft, can solve problems such as increased inflation costs and pipeline rupture, and achieve the effects of protecting equipment safety and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

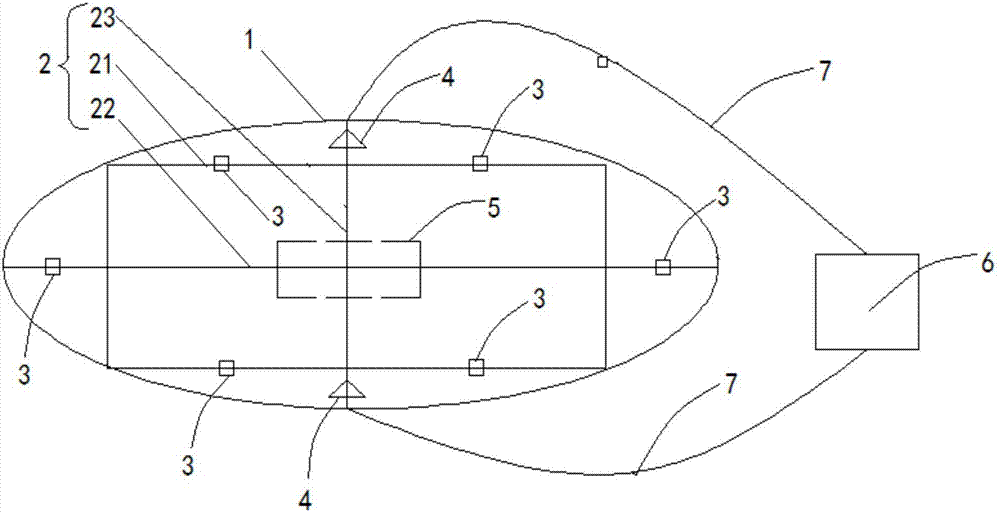

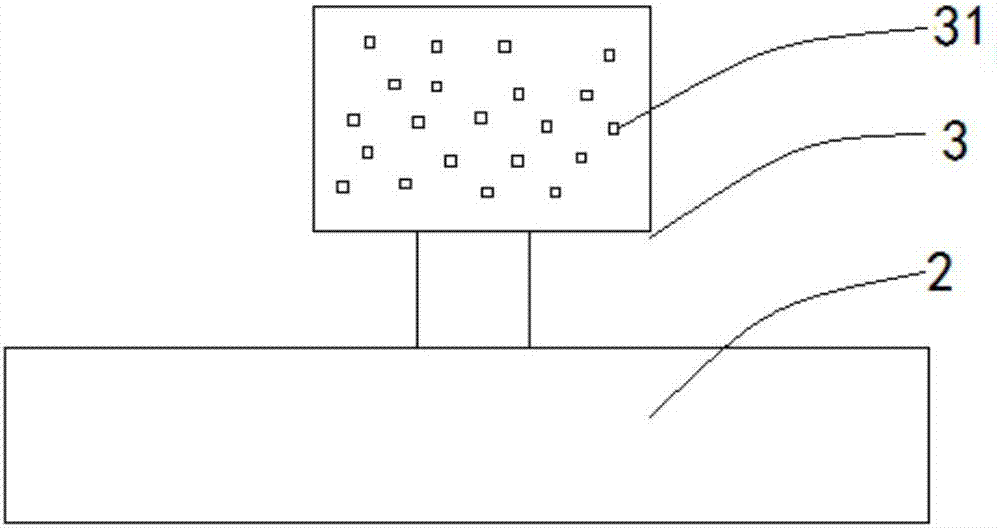

[0029] Such as Figure 1-Figure 2 As shown, a rapid inflation system for an airship capsule includes a capsule 1, a support frame 2, a diffusion device 3 for shunting and decompression, a differential pressure sensor, an inflation joint 4 and a control system 5; the capsule 1 is ellipsoidal, The support frame 2 is made by connecting hollow support rods, and is arranged horizontally in the capsule body 1. The diffusion device 3 is installed on the support frame 2. One end of the diffusion device 3 communicates with the hollow support rod of the support frame 2, and the other end communicates with the capsule body. The inside of the body 1 is connected, the differential pressure sensor is arranged in the capsule body 1 , the inflation joint 4 is installed on both sides of the short axis direction of the capsule body 1 , and the control system 5 is installed in the middle of the support frame 2 . The inflation system is inflated by an external high-pressure gas source 6 through a...

Embodiment 2

[0036] A method for rapidly inflating an airship capsule, comprising the following steps:

[0037] Step 1, using the inflation pipeline 7 to connect the high-pressure gas source 6 to the intake end of the inflation connector 4, and connect the high-pressure gas source 6 to the control system 5;

[0038] Step 2, the control system 5 issues an instruction to start inflation, starts the high-pressure air source 6, and inflates the bladder 1;

[0039] Step 3, when the differential pressure sensor detects that the differential pressure reaches the differential pressure threshold, the control system 5 issues an instruction to stop inflation, turns off the high-pressure gas source 6, and disconnects the inflation pipeline 7 from the gas inlet of the inflation joint 4.

[0040] The pressure difference value is the difference between the gas pressure inside the capsule body 1 and the atmospheric pressure outside the capsule body 1 .

[0041] Step 2 also includes: after starting the hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com