Elevating lift

A lifting mechanism and lifting system technology, applied in the direction of lifting devices, etc., can solve the problems of large structural design, unsuitable for personal use, large volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

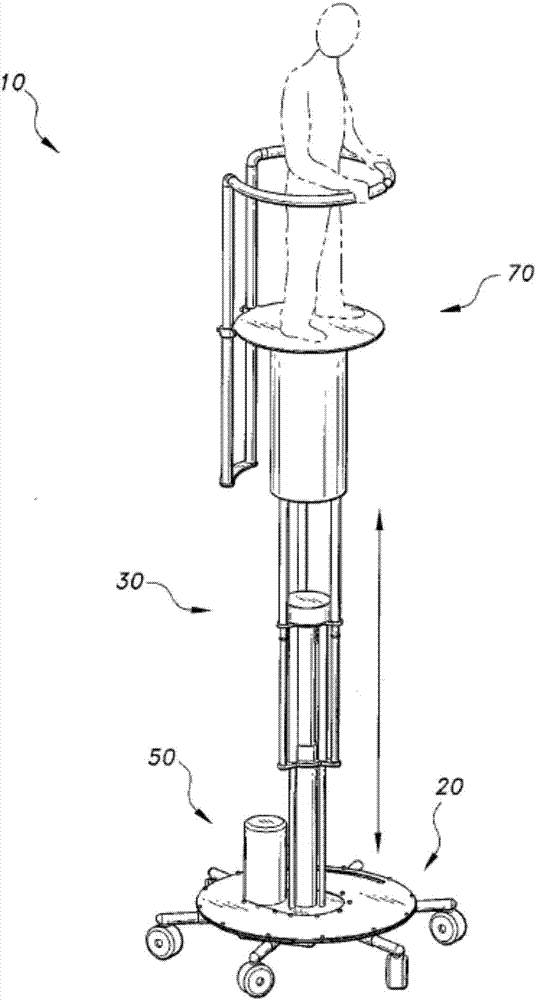

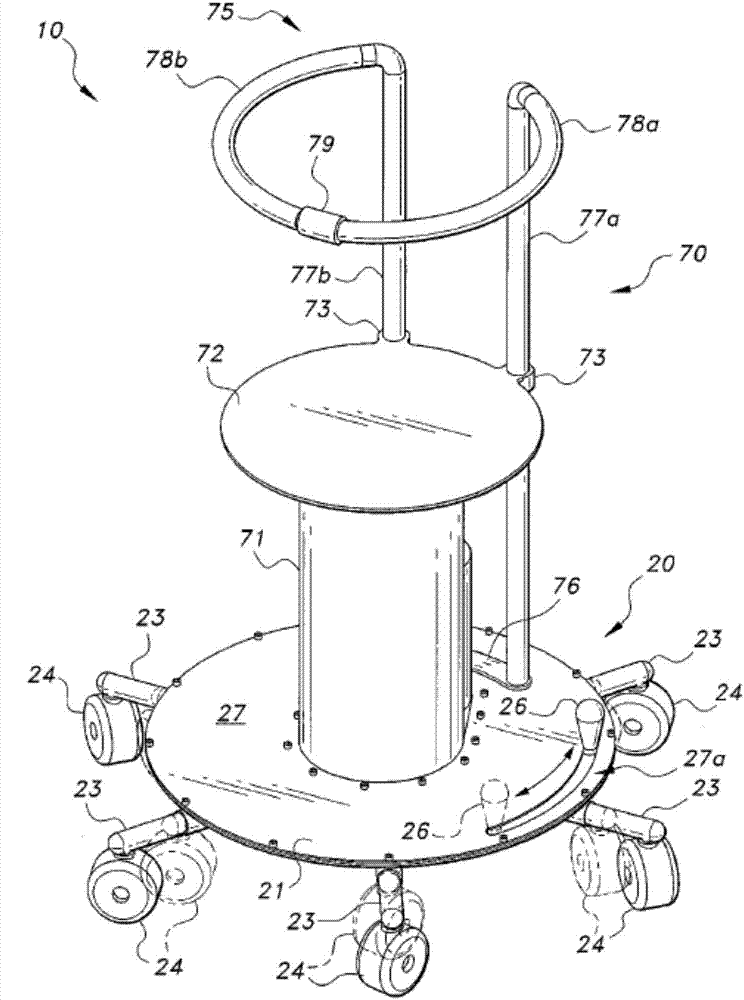

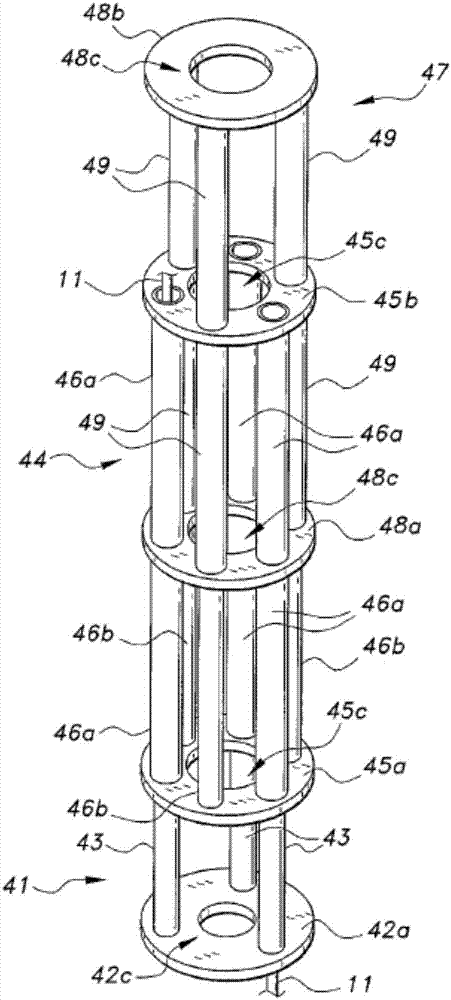

[0021] The lifting mechanism, the first embodiment of which the reference number is 10, is a firm, safe and relatively simple and compact multifunctional lifting mechanism. The lifting mechanism 10 includes a stable base assembly 20 , a freely telescopic lifting system 30 that can extend upwards from the stable base assembly 20 , and a platform assembly 70 that is fixedly connected to the top of the lifting system 30 .

[0022] From attached figure 1 , 2 , 8A and 8B, it can be seen that the stable base assembly 20 supports the lifting system 30 and includes a movable base 21 . A set of freely telescopic casters 24 is hinged to the movable base 21 so that the lifting mechanism 10 can be moved to a desired position. The movable pedestal 21 adopts a circular structure in order to make it easier to manufacture and operate, but it can also be made into other geometric shapes according to requirements.

[0023] A set of extendable bar-shaped support rods 22 radially protrude from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com