Ink sewage treatment system

A sewage treatment system and ink technology, applied in the field of printing, can solve the problems of ink pollution, poor treatment effect, ink pollution, etc., and achieve the effect of good sewage filtration and treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

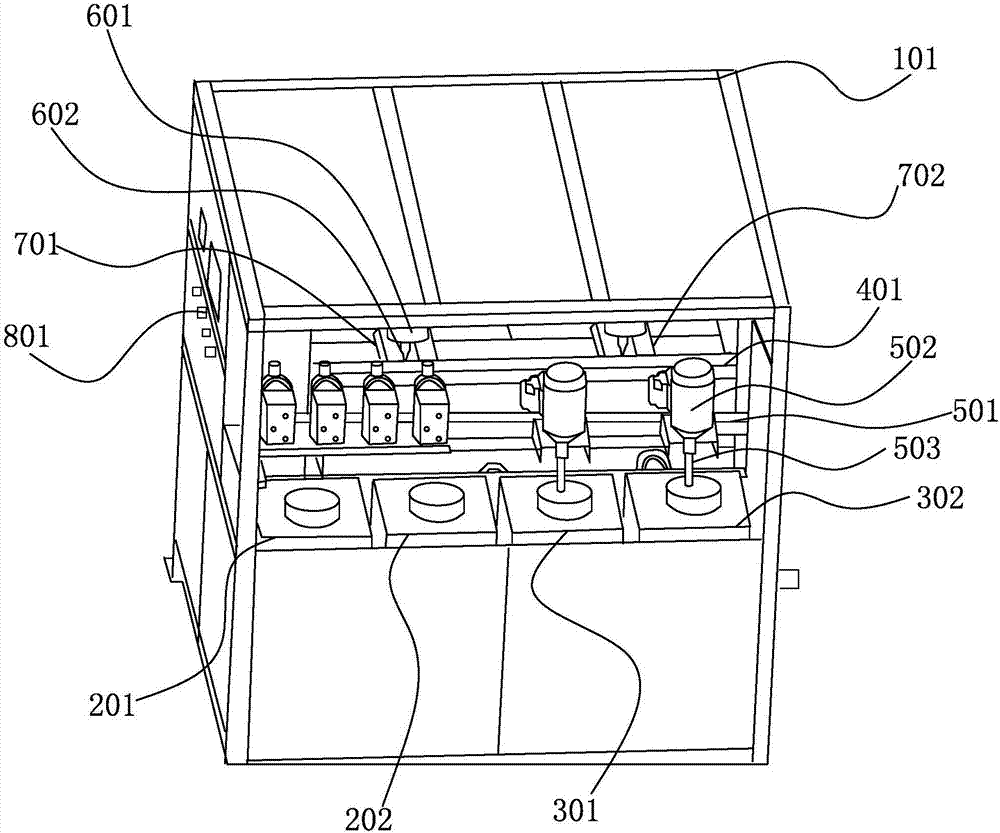

[0031] refer to Figure 1 to Figure 5 The embodiments of the present invention will be further described.

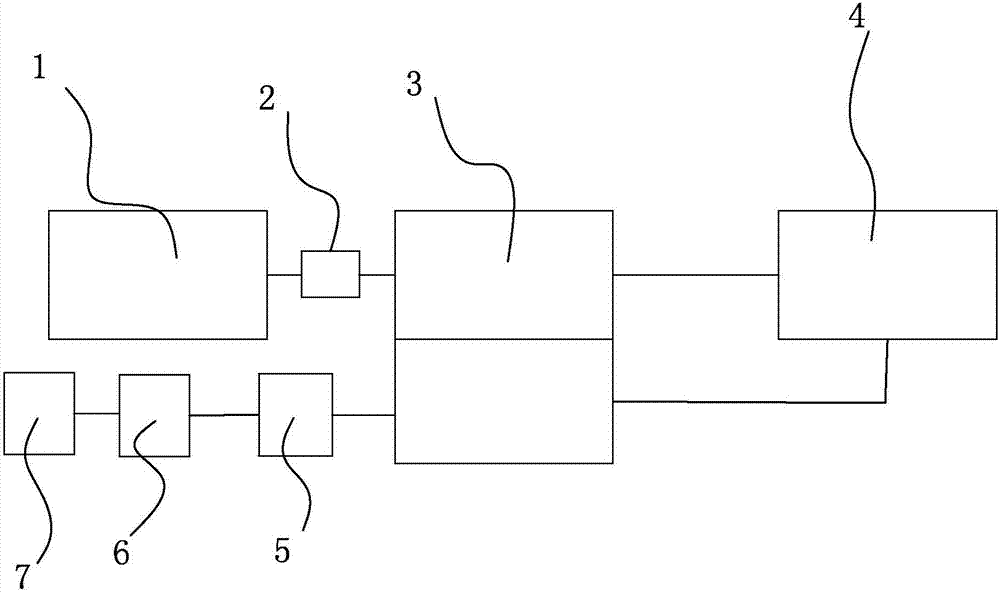

[0032] An ink sewage treatment system, comprising a sewage pool 1 and a filter press 4, a reaction system 3 is arranged between the sewage pool 1 and the filter press 4, the reaction system 3 is connected with a filter system 5, and the filter system 5 is connected with clean water Collection pool7.

[0033] By adopting the above-mentioned technical scheme, through the collection of water-ink sewage from the sewage pool 1, the sewage inside the sewage pool 1 is input into the reaction system 3, and the reaction system 3 is used to react internally, and the reacted solution is output to the filter press 4 After the filter press is carried out in the filter press, the mud mass condensed into large particles cannot pass through the filter, and remains in the filter press 4 to become a mud cake. The filtered mud cake is cleaned, and then the water molecules after the press ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com