In-situ high-pressure dosing device for treatment of contaminated soil

A technology of polluted soil and dosing device, which is applied in the field of soil treatment, can solve the problems of dilution of medicine solution, uneven mixing, affecting the effect of soil pollution treatment, lack of design of medicine solution mixing, etc., so as to improve the treatment effect and ensure the soil treatment effect , the effect of effective mixed processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

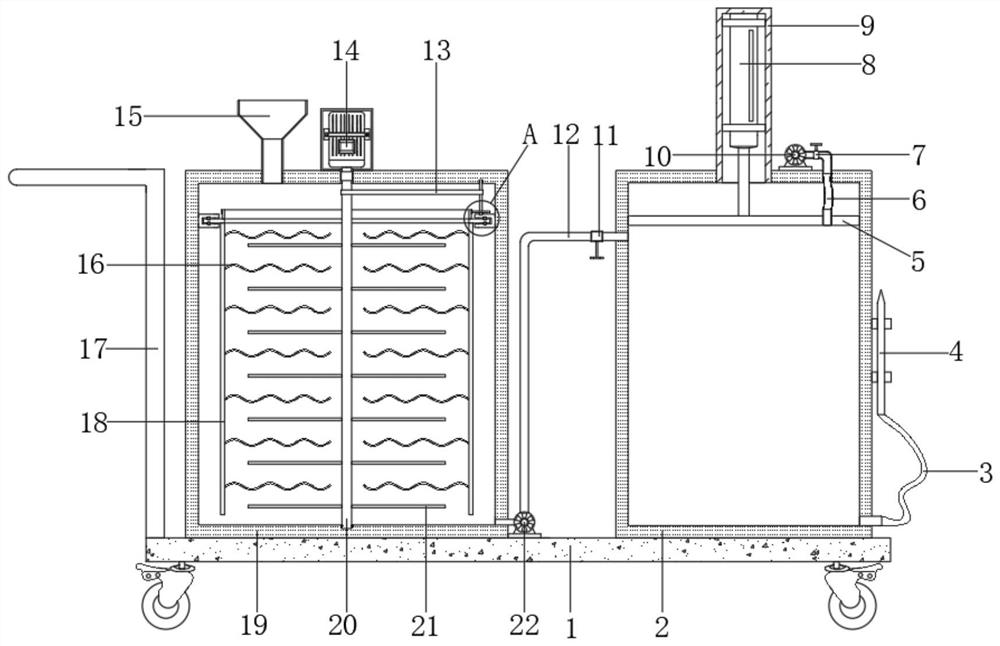

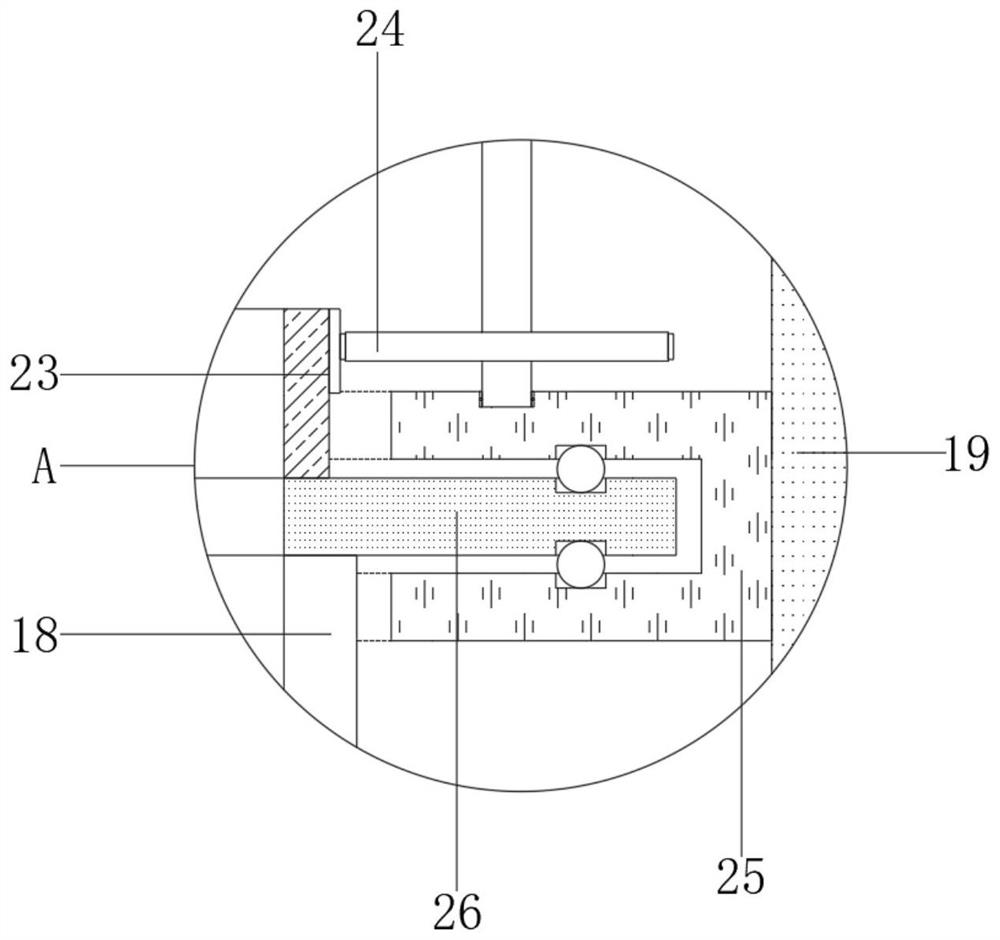

[0026] refer to Figure 1-2 , an in-situ high-pressure dosing device for polluted soil treatment, comprising a base 1 on which moving wheels are fixed at the four corners of the bottom outer wall by bolts, and a mixing tank 19 and a dosing tank 2 are respectively fixed on both sides of the top outer wall of the base 1 by bolts, The top of the dosing tank 2 is welded with a fixed cylinder 9, and the inner wall of the fixed cylinder 9 is fixed with a hydraulic rod 8 by bolts, and the end of the extension rod of the hydraulic rod 8 is fixed with a piston plate 5 by bolts, and the top outer wall of the dosing tank 2 One side is fixed with an air pump 10 by bolts, the output end of the air pump 10 is fixedly connected with an output pipe, and the opposite side of the output pipe and the piston plate 5 is fixedly connected with a corrugated hose-6, and one end of the output pipe is fixedly connected with a seal The valve 7 is welded with a discharge port on one side of the bottom of...

Embodiment 2

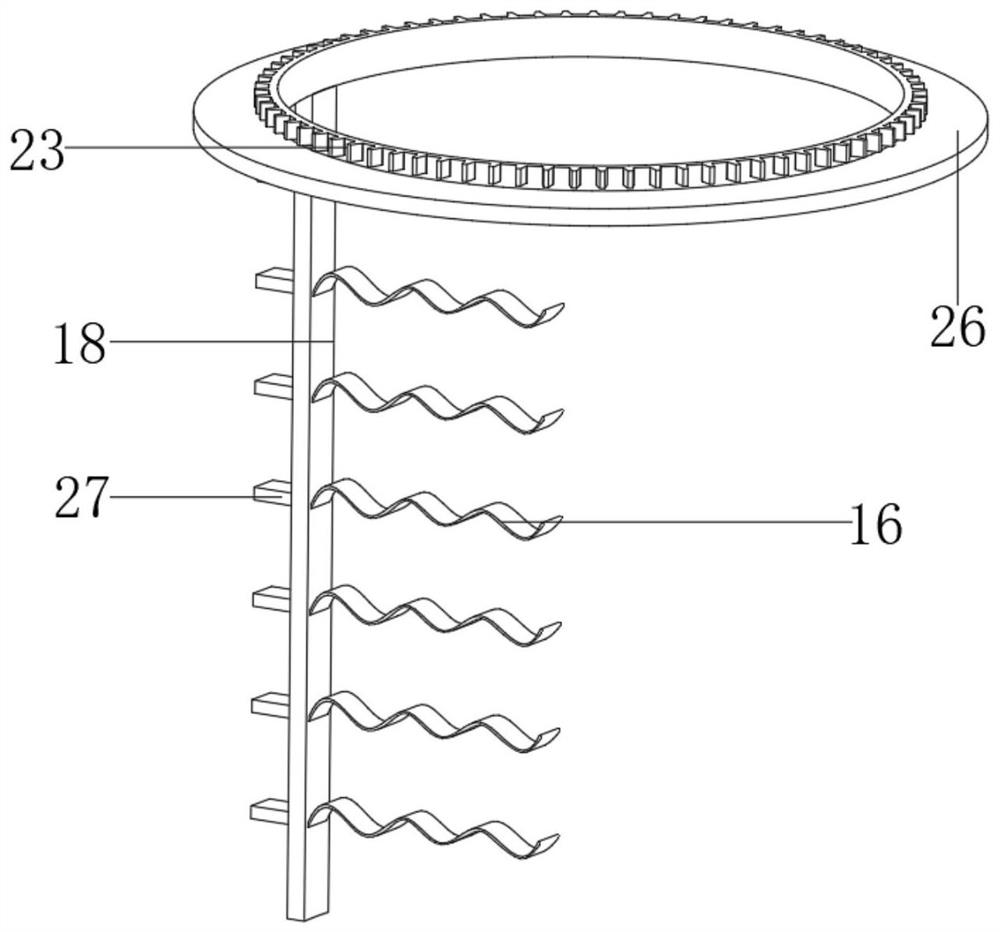

[0034] refer to image 3 , an in-situ high-pressure dosing device for contaminated soil treatment. Compared with Embodiment 1, this embodiment also includes that the other side of the mixing rod 18 is welded with convex plates 27 distributed equidistantly.

[0035] Working principle: When in use, the protruding plate 27 on the other side of the mixing rod 18 is used to rotate with the rotating plate 26 to effectively improve the mixing effect of the mixing rod 18 on the medicinal solution, thereby achieving the purpose of further improving the subsequent soil treatment effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com