A gas control method for soft and outburst coal seams in large mining and long working faces in underground coal mines

A technology for protruding coal seams and working faces, applied in the direction of gas discharge, ground mining, mining equipment, etc., can solve problems affecting the normal succession of mining working faces, large amount of gas control engineering, unfavorable mines, etc., to shorten the time of gas drainage, Reduced economic burden and small accident damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

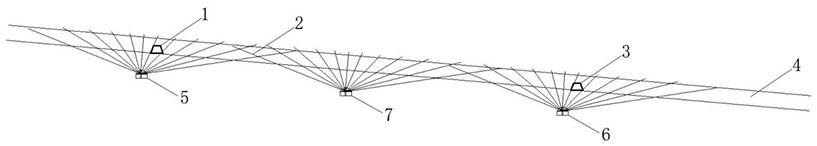

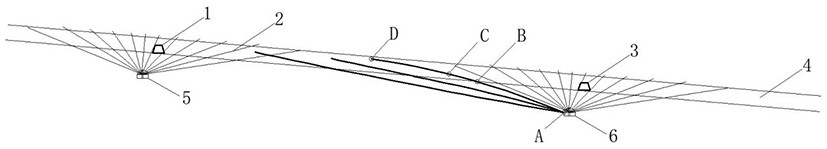

[0030] To this end, the first embodiment of the coal mining work surface of the coal mine well is softly protruding the coal seam gas treatment method, including the following steps:

[0031] The first step: the directional drill is drilled in the coal seam or the bottom plate rock drawing in the laneway, and the directional drill is driven by the designated trajectory by orientation drilling direction, and the coal seam top or the bottom plate is arranged to remove the coal seam;

[0032]Step 2: When the directional penetration drill hole in the first step enters the coal seam, exit the directional drilling rig in the direction of the direction of the drilling, and switch the conventional rotary drill drill pipe with hydraulic punching equipment. Inside the wearing layer, the drilling coal hole segment is applied in the coal seam in a winding method until the drilling is constructed to the design position; the directional penetration drilling is a wearing drilling hole for the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com