A kind of vanadium extraction solvent impregnation resin and its preparation method and application

A technology for impregnating resin and solvent, which is applied in the field of vanadium extraction solvent impregnating resin and its preparation, can solve the problems of long impregnation equilibrium time, low adsorption capacity, low impregnation rate, etc., and achieves shortening impregnation equilibrium time, improving impregnation rate and operation requirements. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

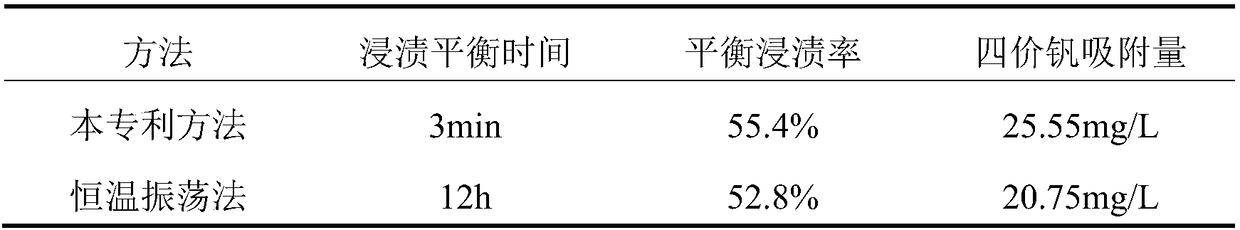

Embodiment 1

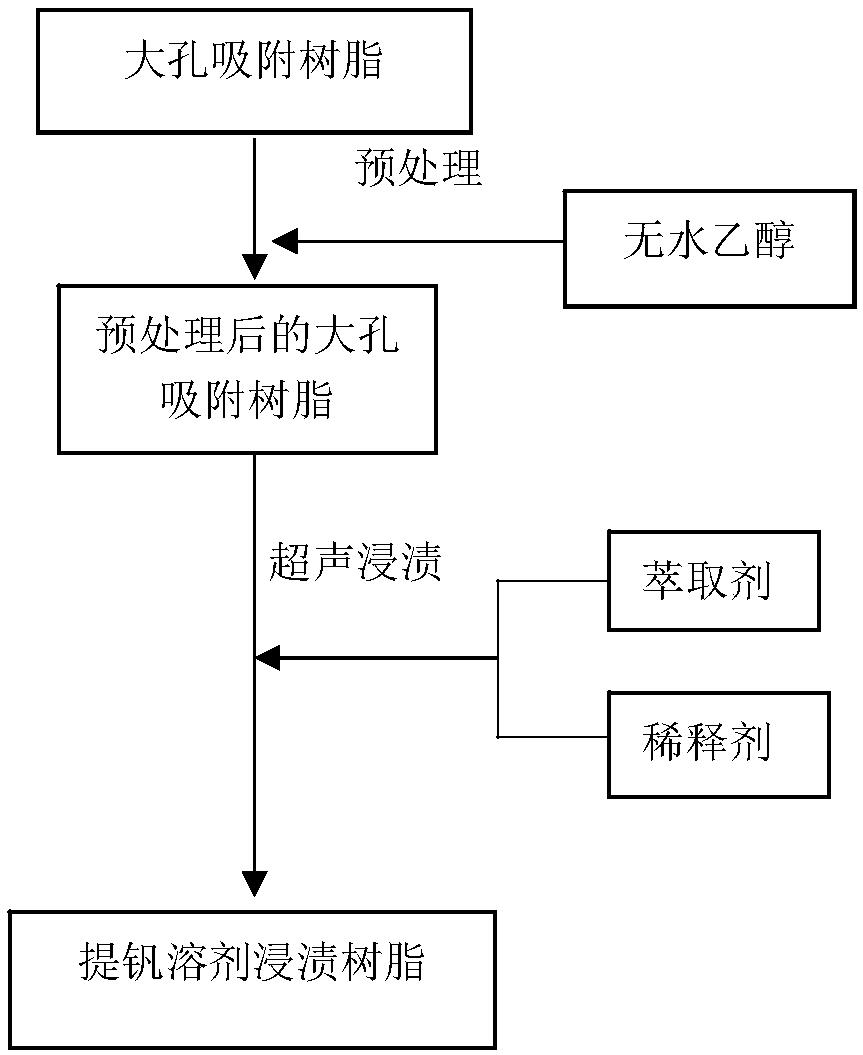

[0023] An ultrasonic preparation method and application of vanadium-extracting solvent impregnated resin, the flow chart of its specific preparation scheme is as follows figure 1 Shown:

[0024] (1) Macroporous adsorption resin pretreatment

[0025] Take 20g of XAD-7HP macroporous adsorption resin (matrix is acrylate), mix ethanol solution and macroporous adsorption resin with a liquid-solid ratio of 2:1mL / g and soak for 2 hours, then wash the soaked macroporous resin with 100-130mL deionized water Pore adsorption resin, and then put the washed macroporous adsorption resin into a vacuum drying oven and dry at 50°C for 4 hours to obtain the pretreated macroporous adsorption resin;

[0026] (2) Preparation of organic extraction solvent

[0027] P204 is mixed with ethanol with a volume ratio of 3:7 to obtain an organic extraction solvent;

[0028] (3) Preparation of Vanadium Extraction Solvent Impregnated Resin

[0029] Get the pretreated macroporous adsorption resin that...

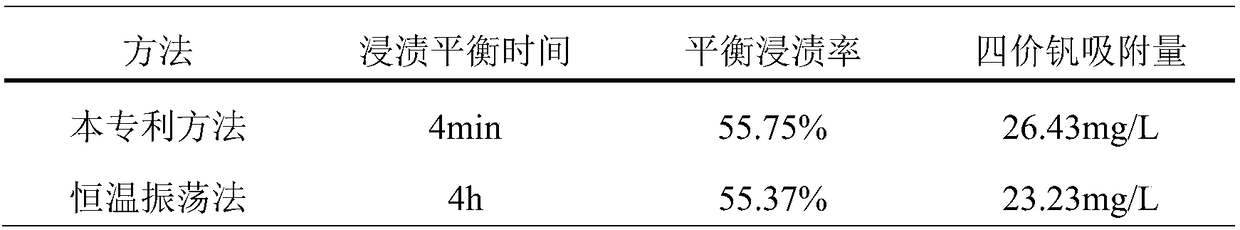

Embodiment 2

[0034] An ultrasonic preparation method and application of vanadium-extracting solvent impregnated resin, the flow chart of its specific preparation scheme is as follows figure 1 Shown:

[0035] (1) Macroporous adsorption resin pretreatment

[0036] Take 20g of XAD-4 macroporous adsorption resin (the matrix is styrene-divinylbenzene copolymer), mix and soak the ethanol solution and macroporous adsorption resin at a liquid-solid ratio of 2.5:1mL / g for 4 hours, and then use 130-160mL to remove Wash the soaked macroporous adsorption resin with ion water, then put the washed macroporous adsorption resin into a vacuum drying oven and dry at 55°C for 5 hours to obtain the pretreated macroporous adsorption resin;

[0037] (2) Preparation of organic extraction solvent

[0038] Mix P507 and ethanol with a volume ratio of 2:5 to obtain an organic extraction solvent;

[0039] (3) Preparation of Vanadium Extraction Solvent Impregnated Resin

[0040] Get the pretreated macroporous ad...

Embodiment 3

[0045] An ultrasonic preparation method and application of vanadium-extracting solvent impregnated resin, the flow chart of its specific preparation scheme is as follows figure 1 Shown:

[0046] (1) Macroporous adsorption resin pretreatment

[0047] Take 20g of XAD-16HP macroporous adsorption resin (the matrix is polyethylene-divinylbenzene copolymer), mix and soak the ethanol solution and macroporous adsorption resin at a liquid-solid ratio of 3:1mL / g for 6 hours, and then use 160-200mL to remove Wash the soaked macroporous adsorption resin with ion water, then put the washed macroporous adsorption resin into a vacuum drying oven and dry at 60°C for 6 hours to obtain the pretreated macroporous adsorption resin;

[0048] (2) Preparation of organic extraction solvent

[0049] Mix N235 and petroleum ether with a volume ratio of 1:1 to obtain an organic extraction solvent;

[0050] (3) Preparation of Vanadium Extraction Solvent Impregnated Resin

[0051] Get the macroporous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com