Multifunctional steel rail drilling machine

A drilling machine and multi-functional technology, which can be used in tracks, track laying, track maintenance, etc., can solve the problems of on-site defense calls, inconvenient drilling operations, and large size, and achieve light weight, low noise, and small size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

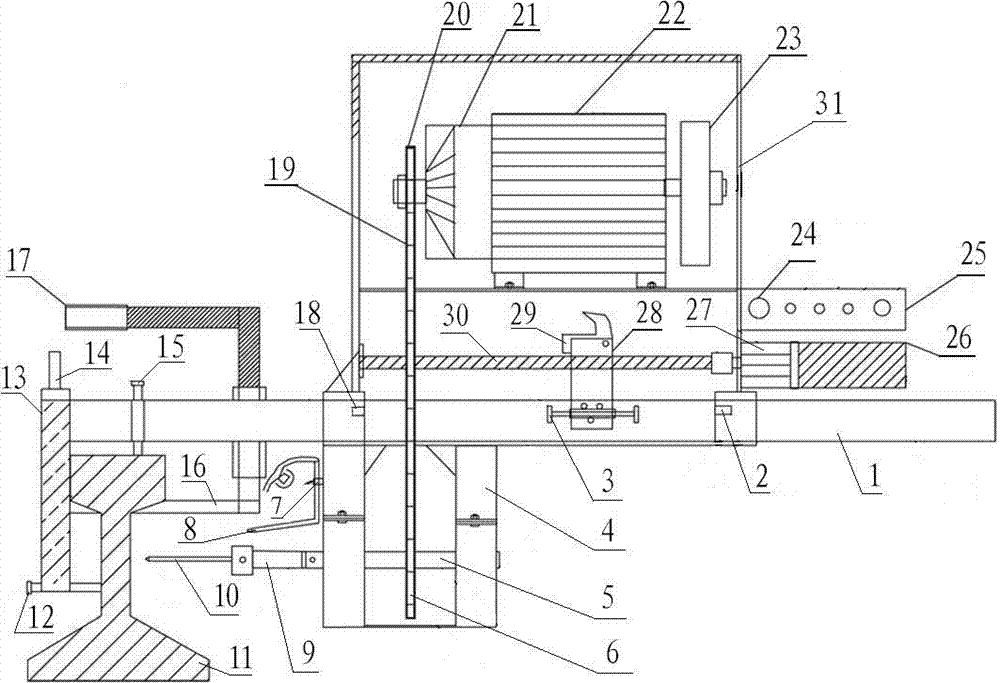

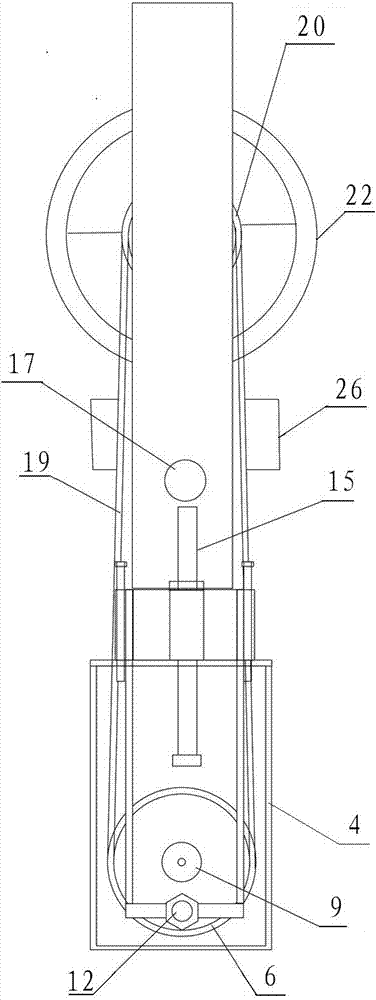

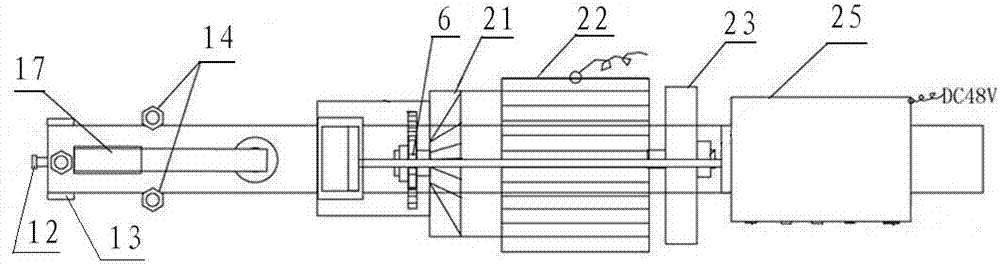

[0019] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

[0020] figure 1 , figure 2 with image 3 The multifunctional rail drilling machine comprises a slide rail 1, one end of the slide rail 1 is provided with a clamping device, the upper side of the other end is provided with an upper box body 31, and the lower side is provided with a lower box body 4; the upper box body 31 A main motor 22 is arranged inside, and a propulsion mechanism is arranged below the main motor 22; a rotating shaft 5 with one end protruding out of the case is installed horizontally in the lower case 4, and a driven sprocket 6 is installed on the rotating shaft 5, and a driven sprocket 6 is installed on the rotating shaft 5, and a driving sprocket 6 is installed on the lower case 4. A drill connector 9 for fixing the drill bit 10 is installed on the outer rotating shaft 5; one end of the output shaft of the main motor 22 is connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com