Vacuum sweeper follow-up type subsidiary sucking plates and vacuum sweeper suction plate structure with same

A vacuum cleaner and follow-up technology, applied in cleaning methods, construction, road surface cleaning, etc., can solve the problems of easy downward tilt, low practicality, collision damage or knock down, etc., and achieve simple structural design and simple structure , the effect of effective walking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

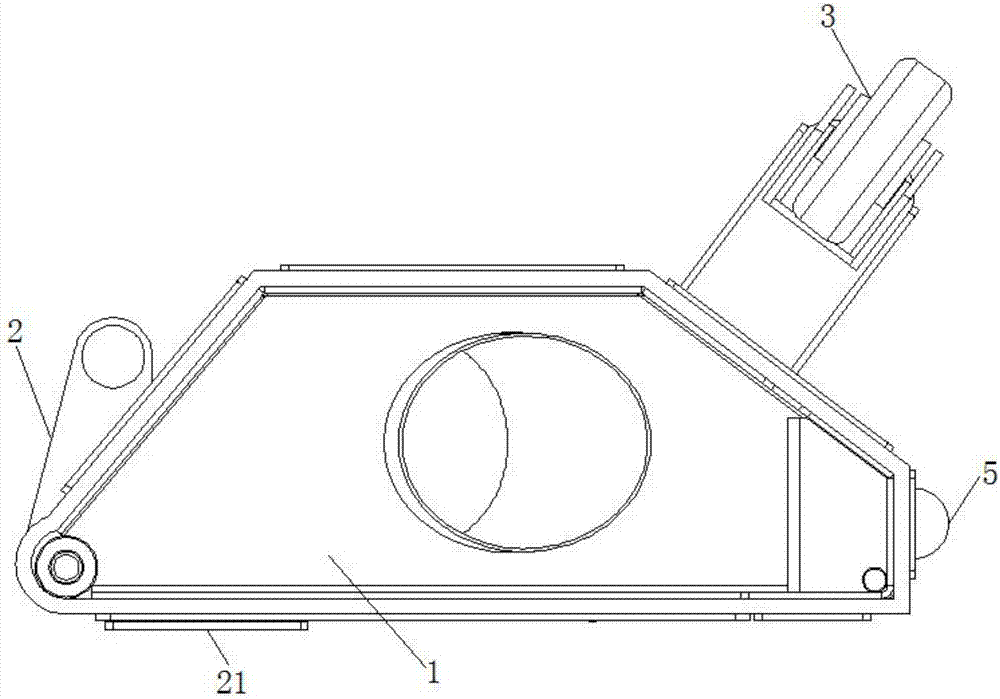

[0038] Embodiment one: if figure 1 with 2 As shown, this embodiment provides a follow-up auxiliary suction cup for a vacuum cleaner, which includes a one-to-one corresponding auxiliary suction cup body 1 and universal traveling wheels 3;

[0039] The above-mentioned auxiliary suction cup body 1 is a shell structure arranged horizontally and with an open lower end, and a dust suction pipe 11 connected to its interior is provided on the top;

[0040] The upper end of one end of the auxiliary suction cup body 1 is rotatably installed with a limited connector 2, and the other end is movably equipped with an anti-collision universal ball 5;

[0041] The lower end of the above-mentioned position-limiting connector 2 is provided with a stopper plate 21 that matches one side end of the above-mentioned auxiliary suction cup body 1;

[0042] The auxiliary suction cup body 1 is provided with an elastic reset device 4, one end of the elastic reset device 4 is fixed on the upper end of t...

Embodiment 2

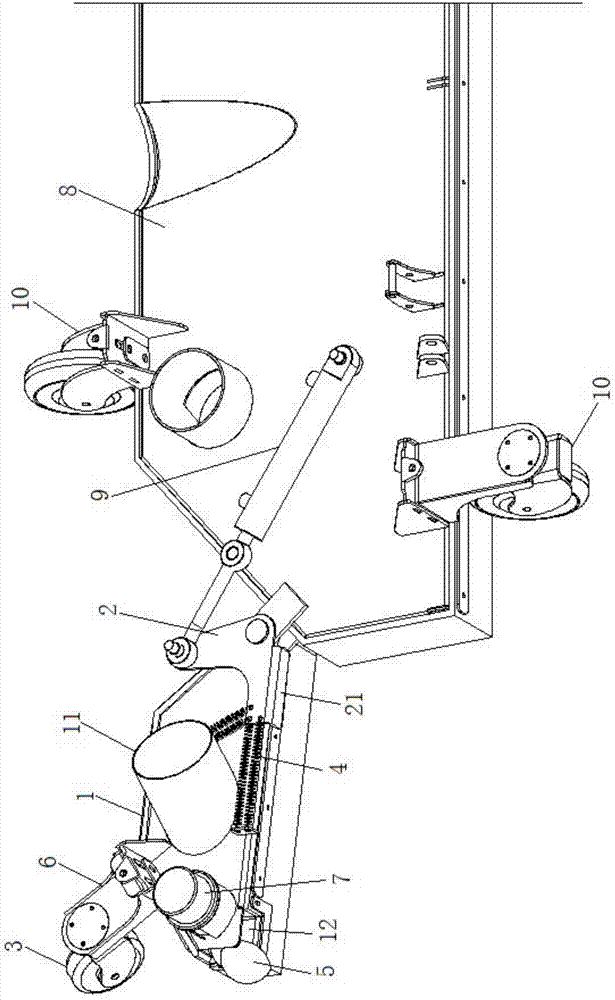

[0052] Embodiment two: if figure 2 As shown, the present embodiment provides a suction cup structure of a vacuum cleaner including a main suction cup 8 and two embodiment-aforementioned follow-up auxiliary suction cups of the vacuum cleaner;

[0053] The limit connectors 2 in the two follow-up auxiliary suction cups of the above-mentioned vacuum cleaners are respectively rotated and installed on the two ends of the above-mentioned main suction cups 8;

[0054] The two ends of the upper end of the above-mentioned main suction cup 8 are respectively equipped with a driving mechanism 9 corresponding to the two auxiliary suction cups of the above-mentioned vacuum truck. rotary connection;

[0055] The above-mentioned driving mechanism 9 can drive the limit connector 2 to rotate through the driving end, and drive the corresponding auxiliary suction cup body 1 to rotate to open or shrink.

[0056] When in use, the entire suction cup is installed on the bottom of the dust collecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com