Vane wheel of extra-low ratio rotating speed centrifugal pump

A centrifugal pump impeller, specific speed technology, applied in the field of mechanical design and manufacturing, centrifugal pump design and manufacturing, can solve the problems of large blade channel and outlet vortex, large pressure pulsation amplitude, low efficiency, etc., to eliminate blade channel vortex and outlet Vortex, reduce energy loss, increase head effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is further described by the following examples. This example is only used to further illustrate the present invention, but it cannot be interpreted as limiting the protection scope of the present invention. Essential improvements and adjustments belong to the protection scope of the present invention.

[0031] to combine Figure 1 to Figure 11 .

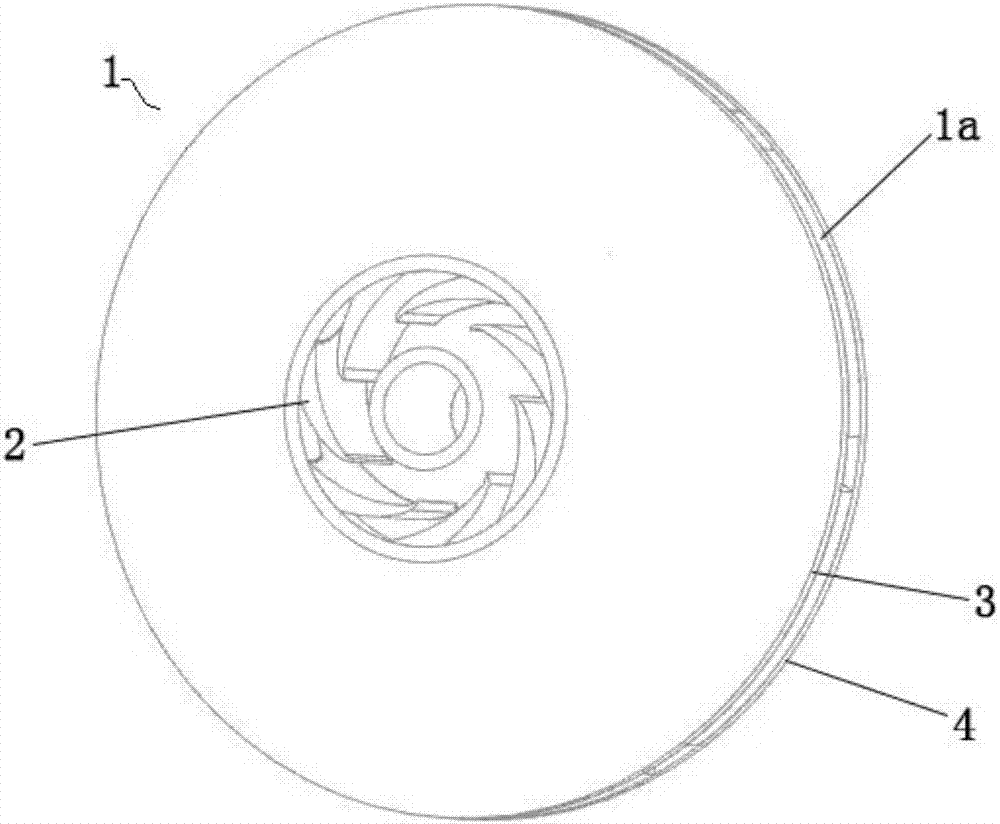

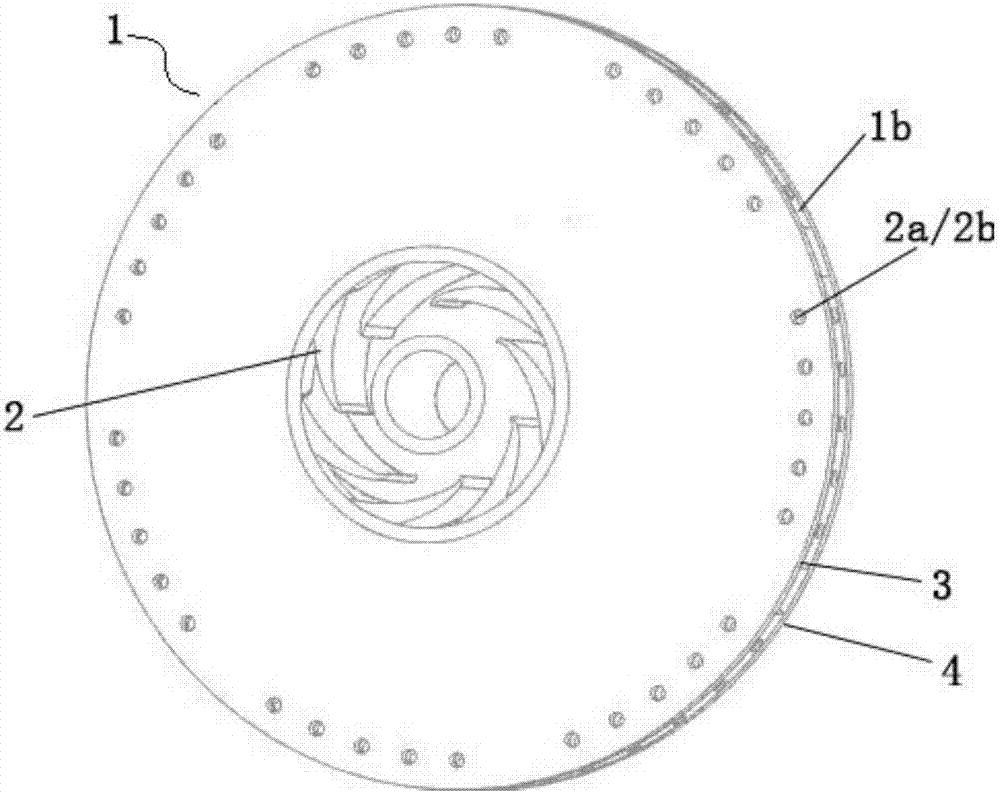

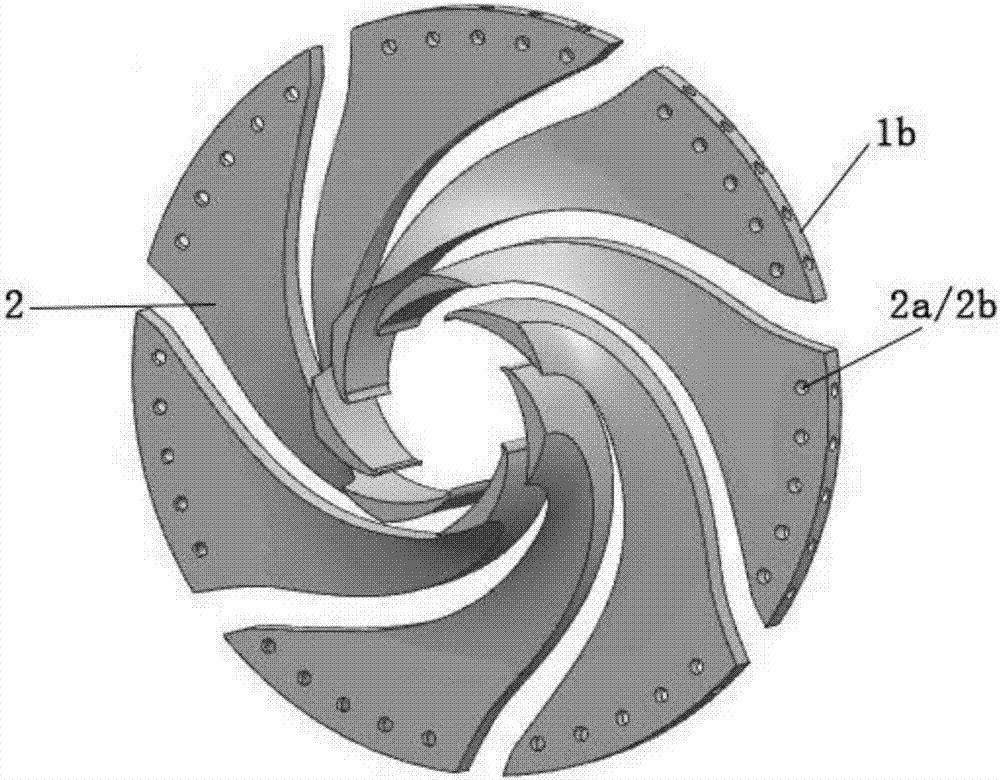

[0032] The ultra-low specific speed centrifugal pump impeller of the present invention, figure 1 , 2 Shown includes front and rear shrouds in the shape of the discs that make up the impeller, figure 2 Contains 6-8 blades with recirculation channels. The front and back molding lines of the blade are composed of multiple arcs and / or straight lines and smooth connections, and the surface of the blade is a ruled surface. Such as image 3 As shown, the front and back sides between adjacent blades constitute the flow path of the impeller and ensure the requirements of the inlet and outlet angles of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com