Pulsation damping device, screw pump and liquid pressure pulsation adjusting method

A pulsation damping, screw pump technology, used in liquid fuel engines, gas/liquid distribution and storage, rotary piston/oscillating piston pump combinations, etc., can solve problems such as poor versatility, eliminate pulsation or reduce pressure pulsation The effect of amplitude, increased pressure cushioning, increased versatility and flexibility of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

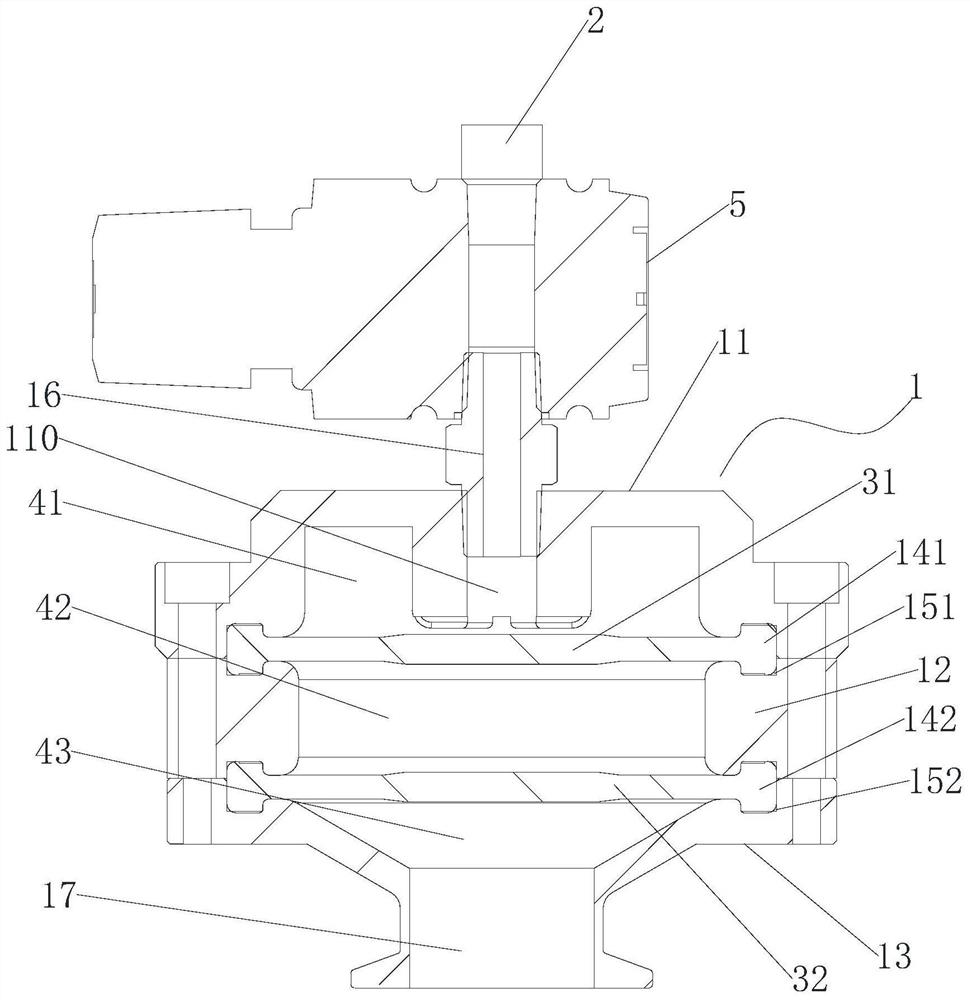

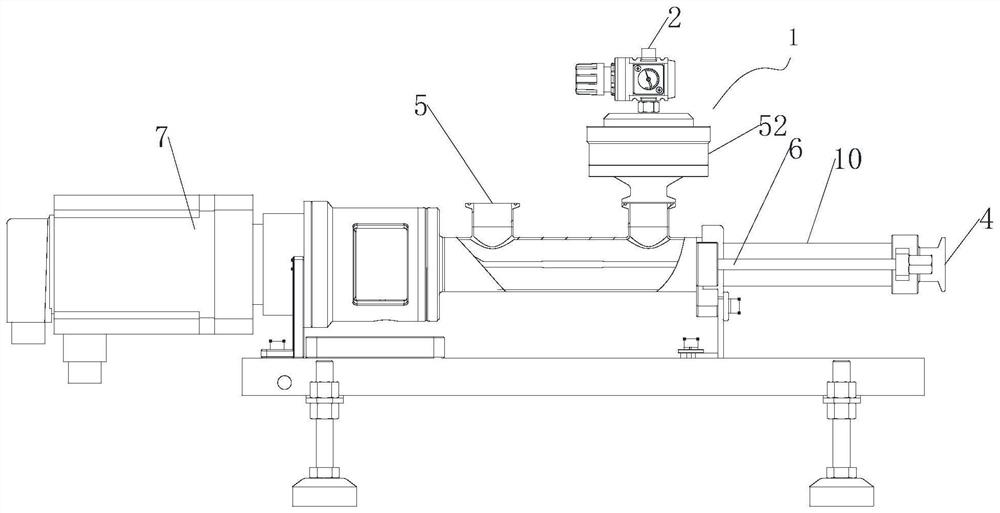

[0026] See figure 1 , a pulsation damping device, which includes a housing 1, an air inlet 2, an elastic diaphragm 3 installed in the housing 1, the air inlet 2 is used to connect with an external air source, the housing 1 is a split structure, It includes a convex upper shell 11, an I-shaped middle shell 12, and a concave lower shell 13 distributed sequentially from top to bottom. The middle part of the upper shell 11 has a first through hole 110 communicating with the air inlet 2, The middle part of the lower casing 13 is provided with a second through hole 130 communicating with the liquid conveying pipeline. In this embodiment, the liquid conveying pipeline is the pump body 10 of the screw pump. See figure 2 ;

[0027] Inside the housing 1 , there are T-shaped slots at the joints between the upper housing 11 and the middle housing 12 , and between the middle housing 12 and the lower housing 13 .

[0028] Diaphragm 3 comprises two, respectively is the first diaphragm 31,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com