Pulsate fluidizing drying machine

A dryer and pulsating flow technology, applied in the drying of solid materials, heating to dry solid materials, drying, etc., can solve the problems of uneven air distribution and unsatisfactory pulsation effect, so as to improve the pulsation effect, improve the working environment, Not easy to cavitation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

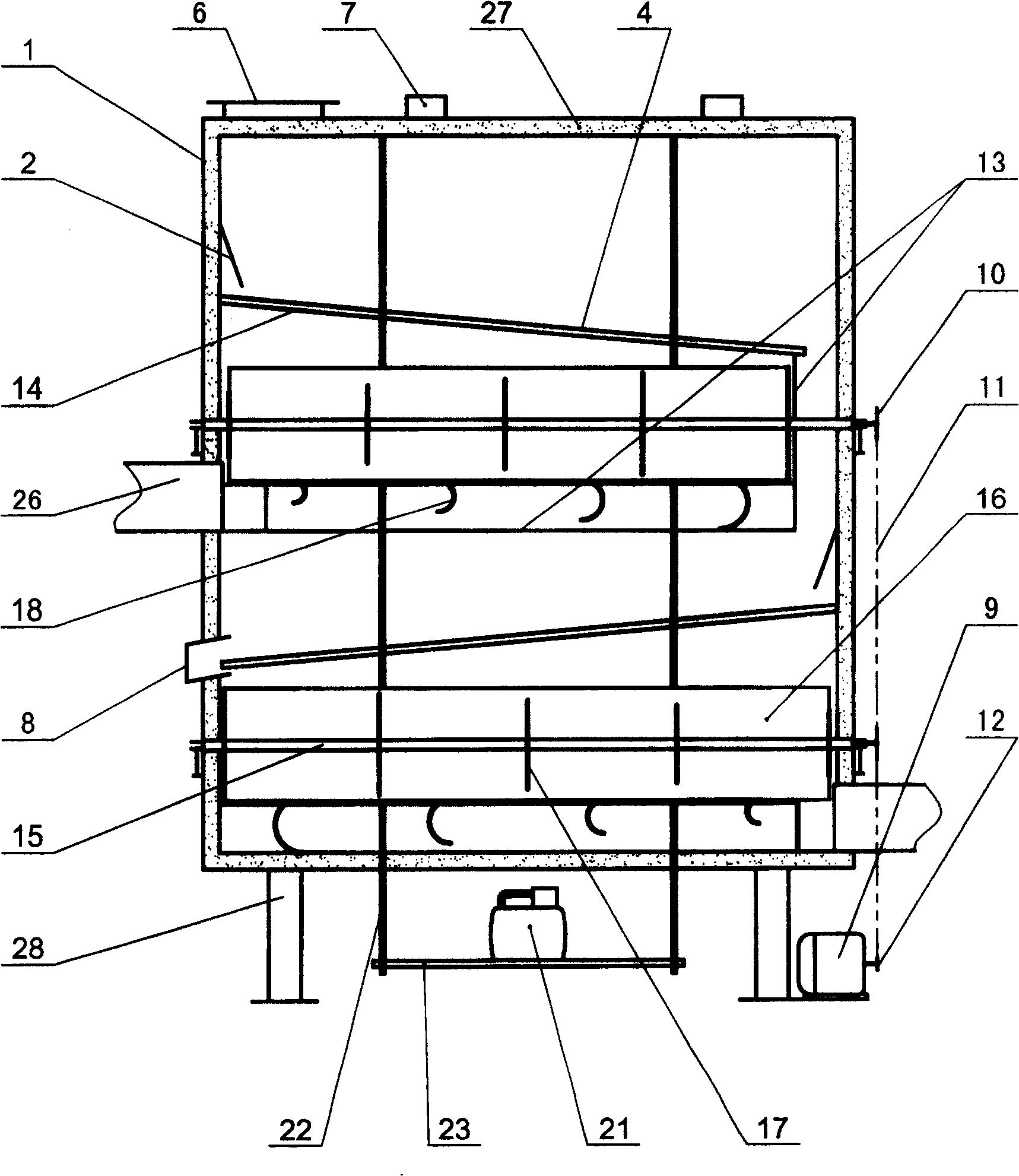

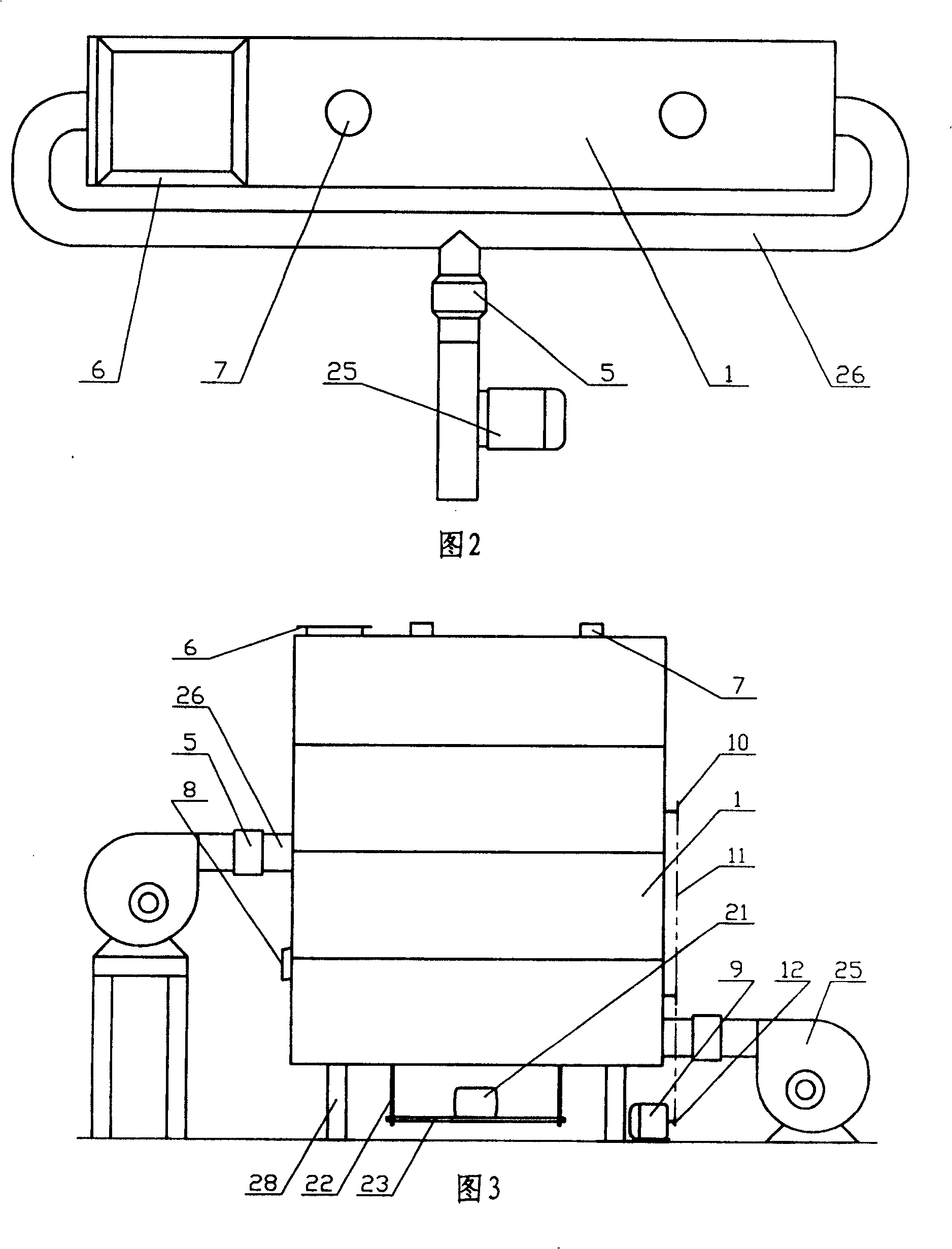

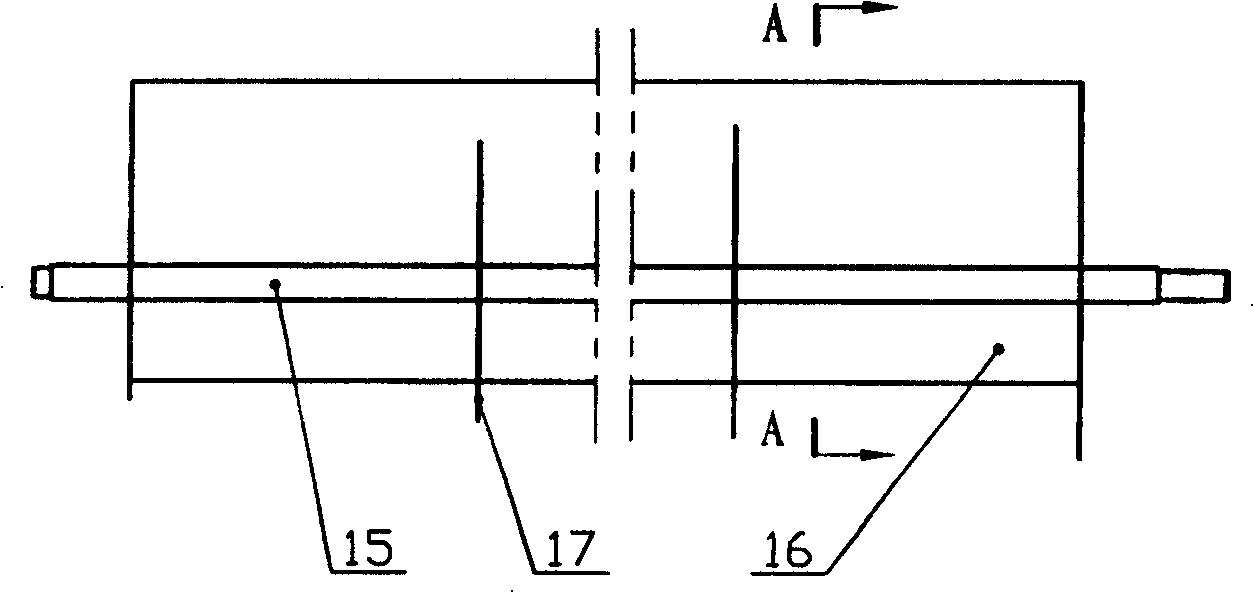

[0023] 1. Box body 2, material guide plate 3, blanking channel 4, rib 5, heating device 6, feed inlet 7, exhaust outlet 8, discharge outlet 9, motor 10, driven sprocket 11, chain 12 , driving sprocket 13, partition 14, fluidized bed 15, transmission shaft 16, blade 17, windshield 18, deflector 19, vertical plate 20, reinforcement plate 21, vibrator 22, flexible rod 23, bracket 24, clamp 25, fan 26, air duct 27, insulation layer 28, base

[0024] exist figure 1, In the embodiment shown in 2, 4, 5, 8, 9, an insulating layer 27 is arranged in the box wall of the drying box body 1, a feed inlet 6 and an air outlet 7 are arranged on the top, and a connecting hole is arranged on the side wall. The air inlet of the air duct 26 is provided with a discharge port 8 at its lower part. Two layers of fluidized bed 14 with opposite inclination directions are arranged inside the box body 1. There are a number of pores evenly distributed on the bed surface. The vibrator 21 is fixed on the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com