Garbage incineration gas inlet intelligent control system

An intelligent control system and waste incineration technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve problems such as complex raw materials, ambient air, water source and soil pollution, and fly ash emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

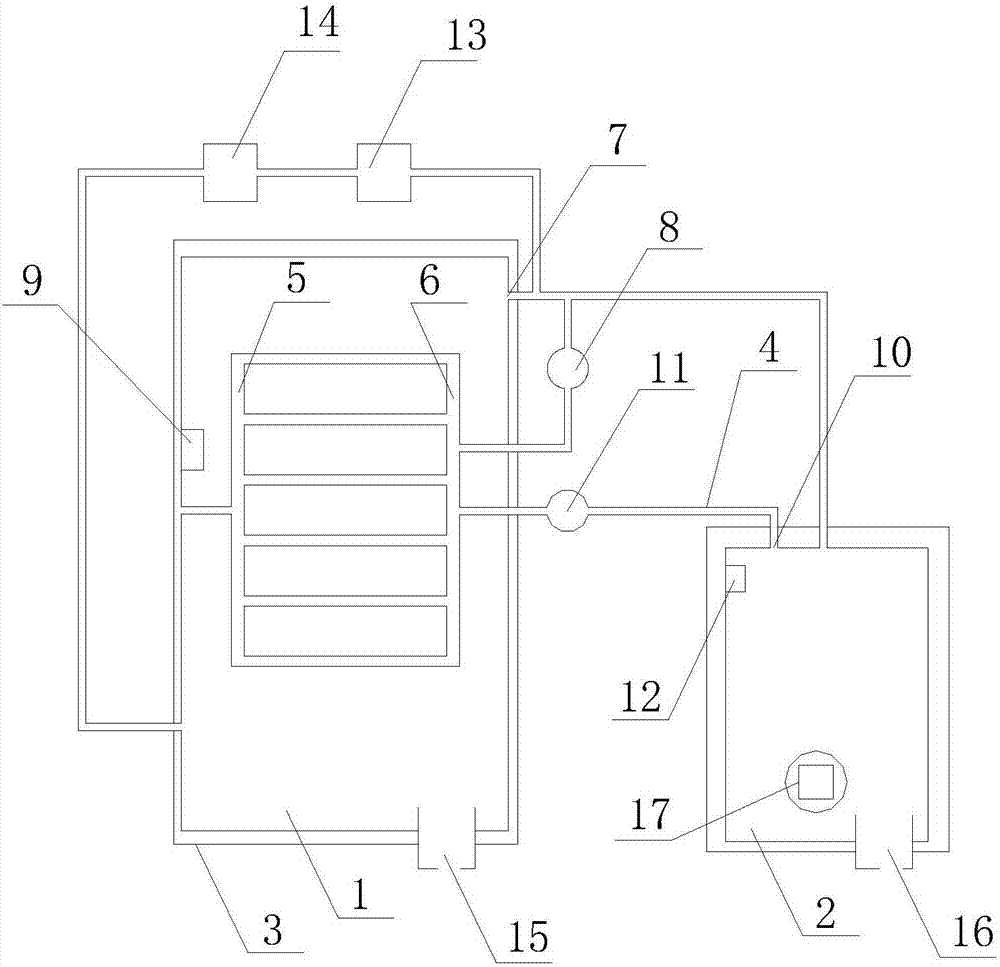

[0023] Such as figure 1 , figure 2 as shown, figure 1 , figure 2 It is an intelligent air intake control system for waste incineration proposed by the present invention.

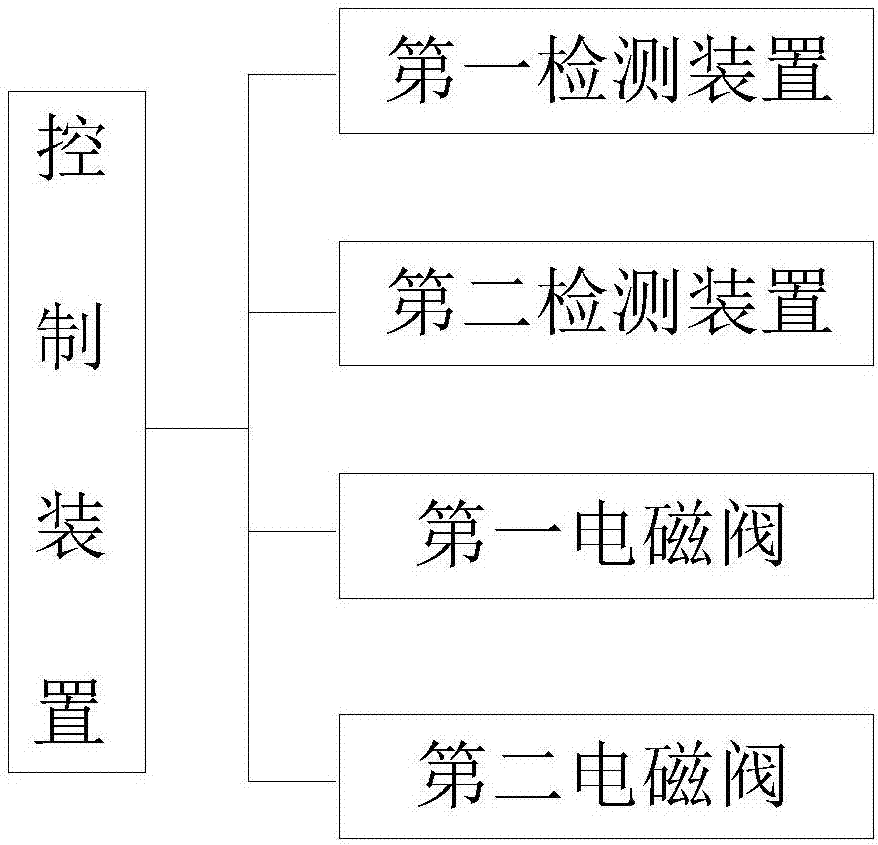

[0024] refer to figure 1 , figure 2 , the waste incineration air intake intelligent control system proposed by the present invention includes: a first cavity 1, a second cavity 2, a casing 3, an exhaust gas channel 4, and a control device;

[0025] The first cavity 1 is arranged inside the shell 3, and a gas channel for gas circulation is formed between the outer wall of the first cavity 1 and the inner wall of the shell 3, and a first pipeline 5 and a second pipeline are arranged vertically inside the first cavity 1 6. The first pipeline 5 is in communication with the gas passage pipeline, and a plurality of horizontal pipelines are arranged between the first pipeline 5 and the second pipeline 6, and one end of the above-mentioned multiple horizontal pipelines is connected with the first pipeline 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com