A method for safely dismantling submunitions

A technology of sub-munitions and bullets, which is applied in the field of safe dismantling of sub-munitions, can solve the problems of inability to guarantee the personal safety of operators and many safety hazards, and achieve the effect of eliminating potential safety hazards, simple method, and reliable protection of personal and property safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The safe disassembly method of sub-munition of the present invention comprises the following steps:

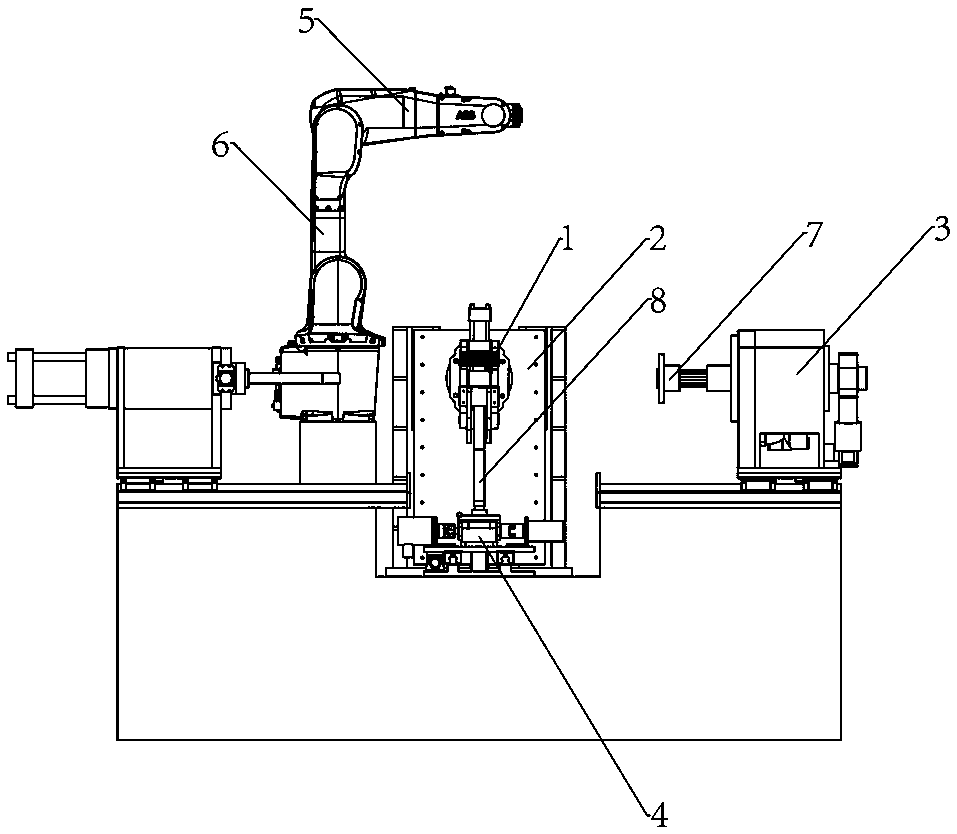

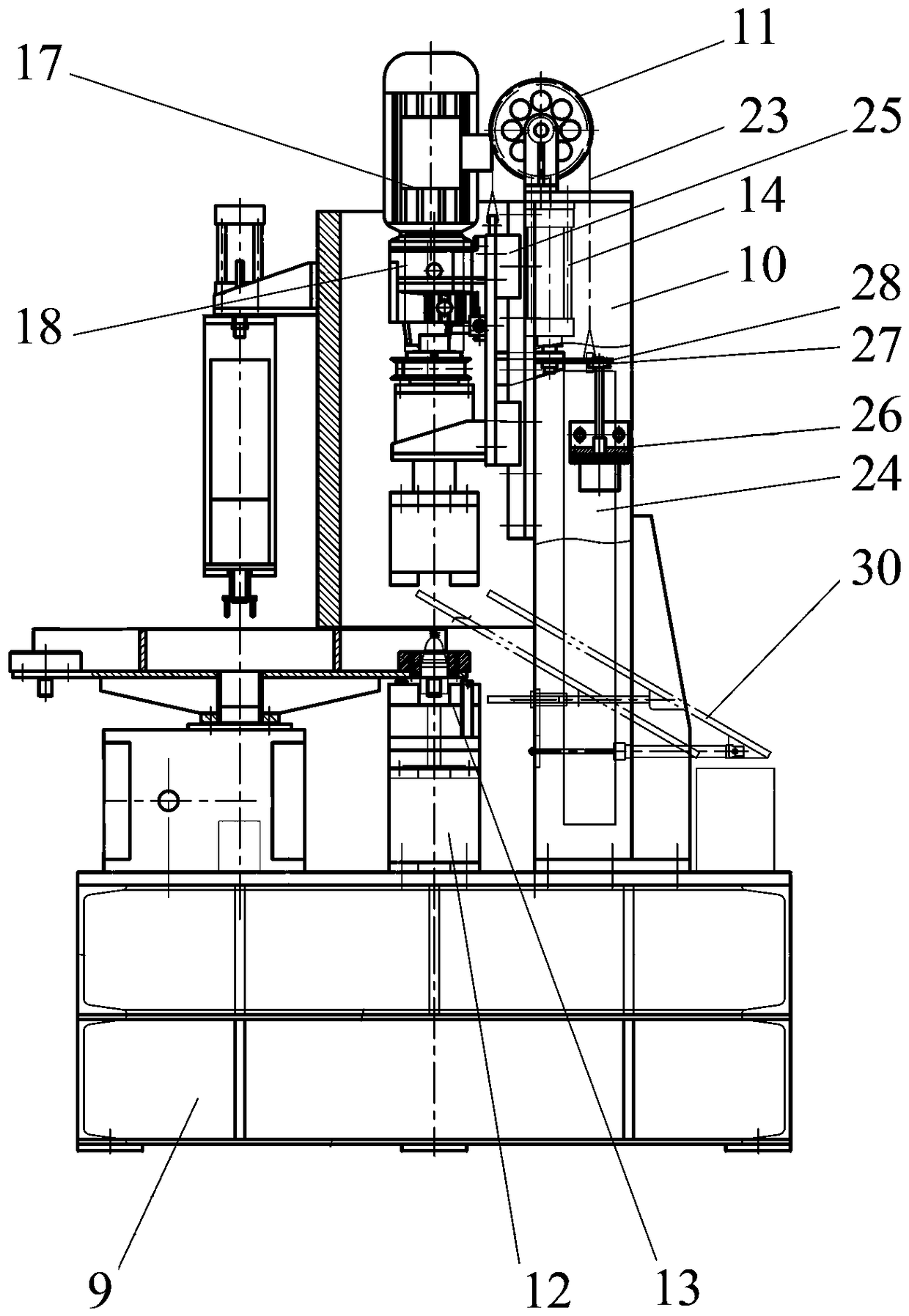

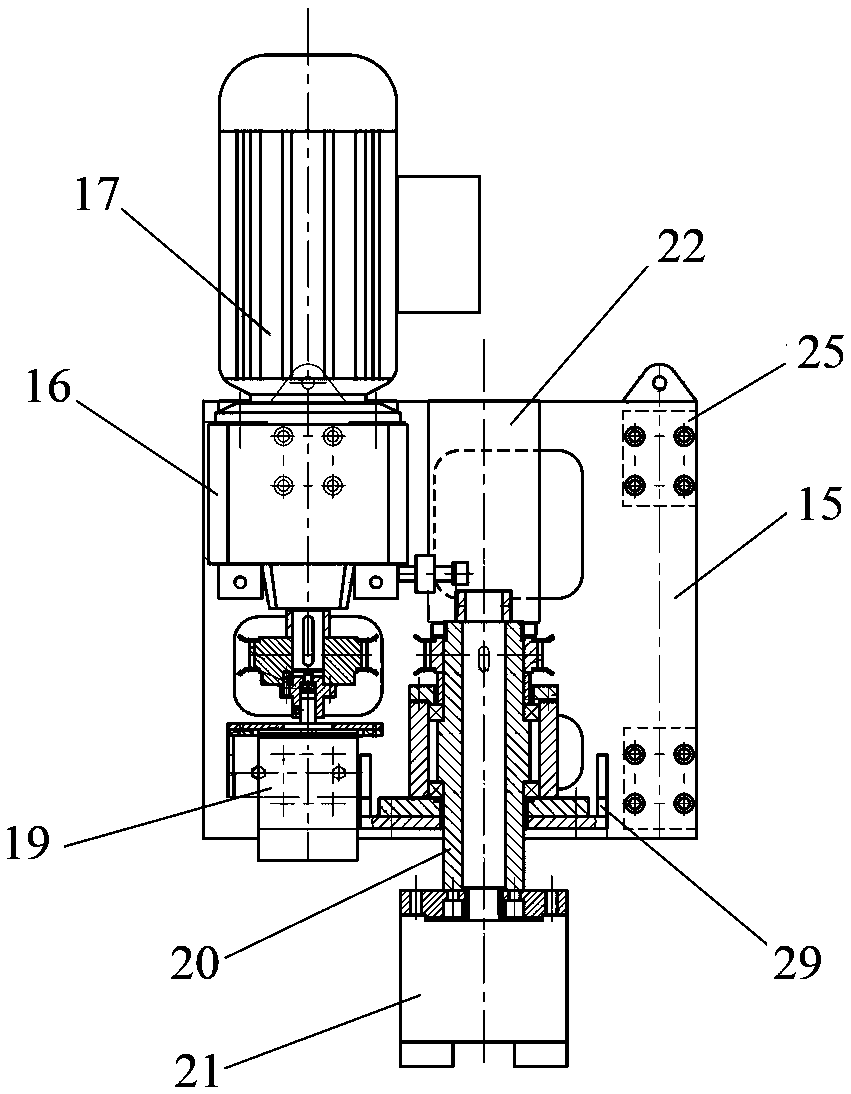

[0021] a. Send the mother bomb to the mother bomb decomposition station, such as figure 1 As shown, a positioning and clamping device 1 for clamping the parent bomb, a rotating device 2 for driving the positioning and clamping device 1 to rotate, and a bottom screw unloading device 3 for disassembling the bottom screw of the parent bomb are provided at the bomb disassembly station. , the ejector device 4 used to push out the bullet in the parent bullet, the fixed tendon key removal manipulator (not shown) and the bullet removal manipulator 5 arranged above the positioning and clamping device 1, and the fixed tendon key driven in an alternative mode Remove the mechanical arm 6 of the manipulator and bullet removal manipulator 5 actions;

[0022] After the bullet enters the disassembly station of the bullet, the positioning and clamping device 1 clamps the bullet. At thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com