On-line Dilution Monitoring Method of Total Hydrocarbons in Exhaust Gas

A technology for waste gas and waste gas pipelines, which is used in measuring devices, instruments, scientific instruments, etc., can solve the problems of long response time and inability to monitor a large range of monitoring technology, and achieve the effect of short response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

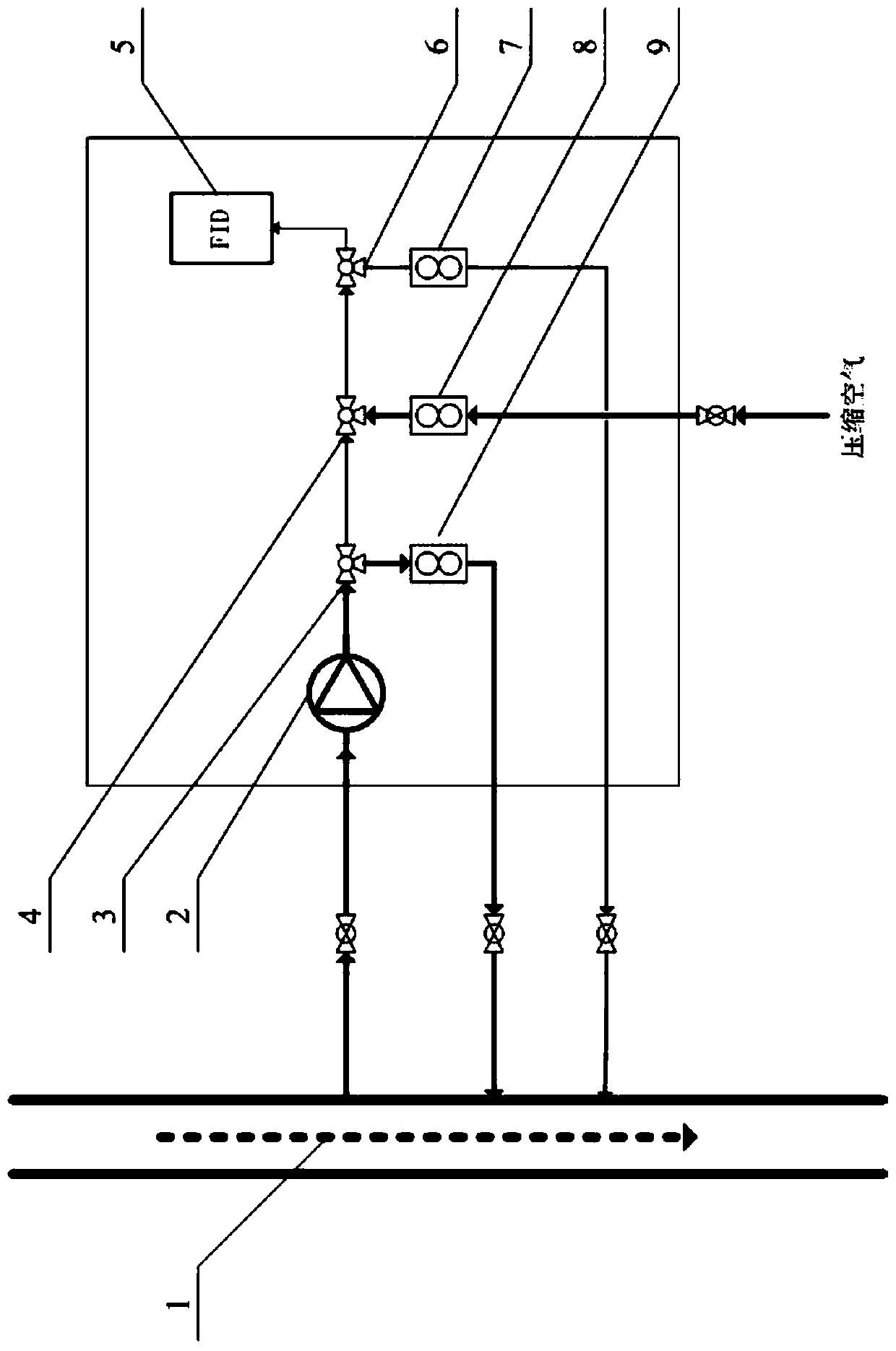

[0017] An on-line dilution monitoring method for total hydrocarbons in exhaust gas, the gas path connection is as follows figure 1 As shown, the exhaust gas 1 in the pipeline passes through the sampling port, passes through the ball valve, and then is sucked by the large-flow sampling pump 2 along the gas pipeline, and then enters the three-way valve 3. Most of the gas samples are discharged through the flow meter 9 with a controller. Return to the exhaust gas pipeline, and the remaining gas samples pass through the three-way valve 4 and the three-way valve 6 successively, and then are sent to the hydrogen flame ionization detector (FID) for detection. On the valve 4, the other outlet of the three-way valve 6 is connected back to the waste gas pipeline. The gas sampling pipelines mentioned in the figure are all stainless steel pipelines with an inner diameter of 4mm except for the section from the three-way valve 6 to the FID detector, which has an inner diameter of 1mm. The l...

Embodiment 2

[0021] An on-line dilution monitoring method for total hydrocarbons in exhaust gas, the gas path connection is as follows figure 1 As shown, the exhaust gas 1 in the pipeline passes through the sampling port, passes through the ball valve, and then is sucked by the large-flow sampling pump 2 along the gas pipeline, and then enters the three-way valve 3. Most of the gas samples are discharged through the flow meter 9 with a controller. Back to the exhaust gas pipeline, the remaining gas samples pass through the three-way valve 4 and three-way valve 6 successively, and then are sent to the hydrogen flame ionization detector for detection. At the same time, the external compressed air passes through the flow meter 8 as a dilution gas and is connected to the three-way valve 4 , the other outlet of the three-way valve 6 is connected back to the waste gas pipeline. The gas sampling pipelines mentioned in the figure are all stainless steel pipelines with an inner diameter of 4mm exce...

Embodiment 3

[0026] An on-line dilution monitoring method for total hydrocarbons in exhaust gas, the gas path connection is as follows figure 1 As shown, the exhaust gas 1 in the pipeline passes through the sampling port, passes through the ball valve, and then is sucked by the large-flow sampling pump 2 along the gas pipeline, and then enters the three-way valve 3. Most of the gas samples are discharged through the flow meter 9 with a controller. Return to the exhaust gas pipeline, and the remaining gas samples pass through the three-way valve 4 and the three-way valve 6 successively, and then are sent to the hydrogen flame ionization detector (FID) for detection. On the valve 4, the other outlet of the three-way valve 6 is connected back to the waste gas pipeline. The gas sampling pipelines mentioned in the figure are all stainless steel pipelines with an inner diameter of 4mm except for the section from the three-way valve 6 to the FID detector, which has an inner diameter of 1mm. The l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com