A method for manufacturing an integrated three-dimensional LED display module

A technology of three-dimensional display and manufacturing method, which is applied in the direction of identification devices, instruments, optics, etc., can solve problems such as complex process, crosstalk of polarized light, and influence on 3D display effect, and achieve the effect of simple process and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

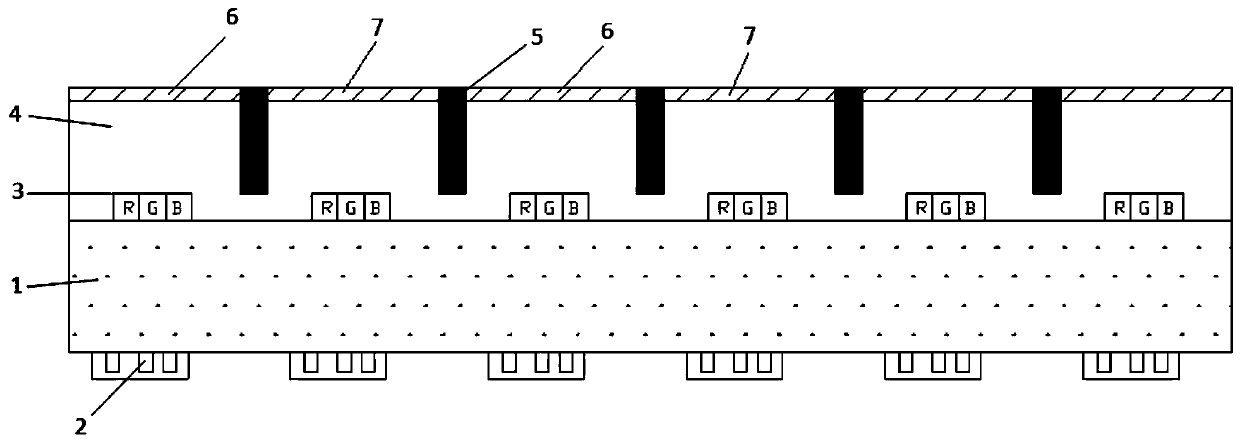

[0035] like figure 1 As shown, the integrated package LED display module includes a driver IC2, a driver circuit board 1, an LED lamp module 3, and an encapsulation glue 4. The driver IC2 is welded on the back of the driver circuit board 1, and the LED lamp module 3 is fixed on the driver circuit board 1. On the front side, the size of the blue and green LED chips is: 7mils*9mils, and the size of the red LED chips is 6mils*6mils. The thickness of the encapsulant 4 is not specifically limited. Encapsulation glue 4 adopts epoxy resin AB glue, and the ratio of component A to component B is 2:1. A scattering agent is added to the packaging glue 4, wherein the proportion of the scattering agent is 5.3%-10.6% of the total mass of the epoxy resin AB glue.

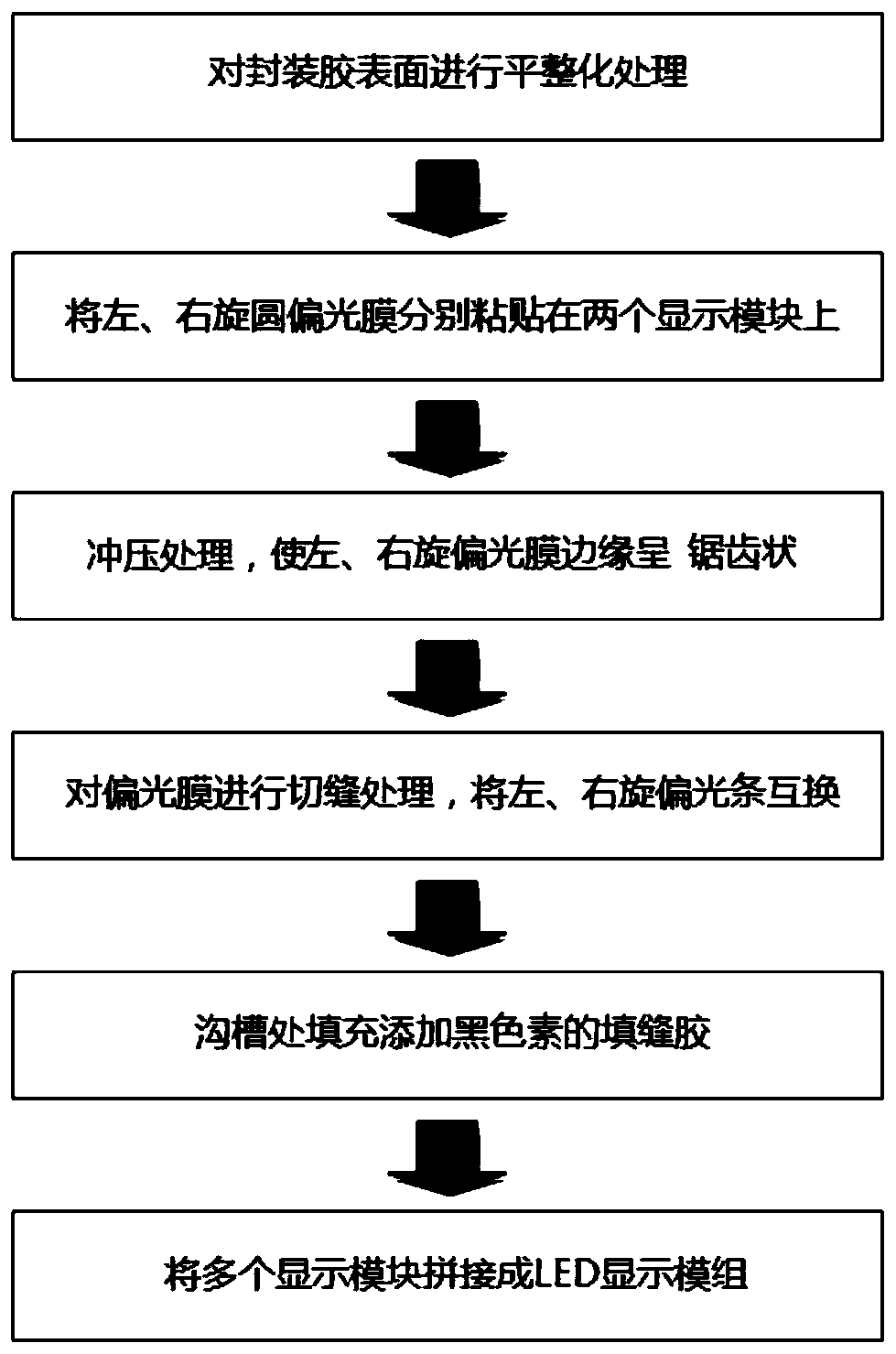

[0036] like figure 2 As shown, the manufacturing method of the LED display module is as follows:

[0037] Step 1: Use the method of fine milling or grinding to process the surface flatness of the packaging glue 4 of the displ...

Embodiment 2

[0048] like figure 1 As shown, the integrated package LED display module includes a driver IC2, a driver circuit board 1, an LED lamp module 3, and an encapsulation glue 4. The driver IC2 is welded on the back of the driver circuit board 1, and the LED lamp module 3 is fixed on the driver circuit board 1. On the front side, the size of the blue and green LED chips is: 7mils*9mils, and the size of the red LED chips is 6mils*6mils. The thickness of the encapsulant 4 is not specifically limited. Encapsulation glue 4 adopts epoxy resin AB glue, and the ratio of component A to component B is 2:1. A scattering agent is added to the packaging glue 4, wherein the proportion of the scattering agent is 5.3%-10.6% of the total mass of the epoxy resin AB glue.

[0049] like Image 6 As shown, the manufacturing method of the LED display module is as follows:

[0050] Step 1: Use fine milling or grinding to process the surface flatness of the packaging glue 4 of the display module, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com