A kind of oled screen body and fiber material integrated structure and preparation method

A fiber material and fiber technology, which is applied in the integrated structure of OLED screen body and fiber material and its preparation field, can solve the problem of poor shock absorption effect of the protective shell, etc., and achieve the effect of light weight, soft shape and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

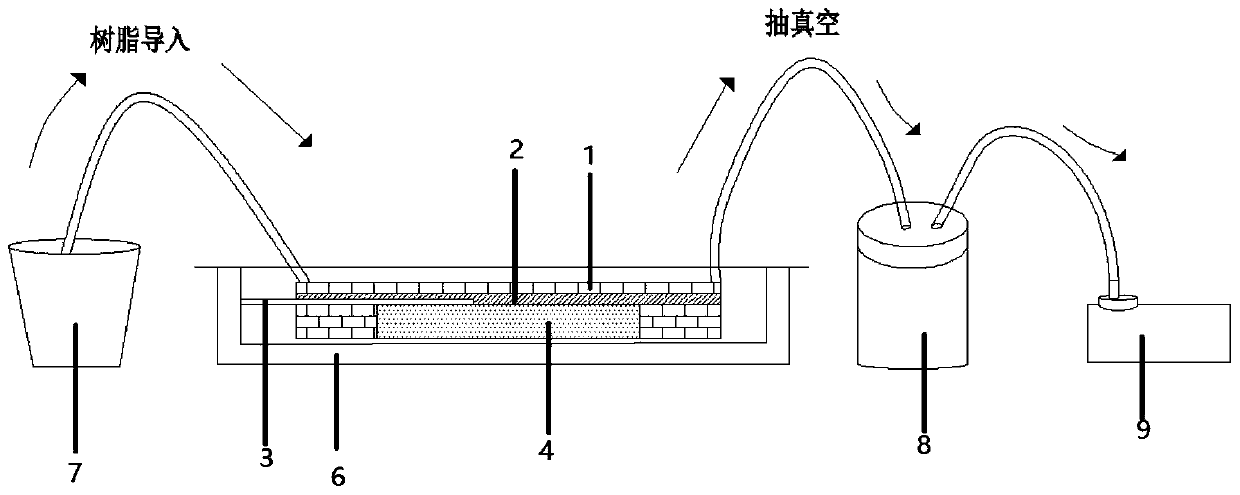

[0037] The preparation method of the integrated structure of OLED screen body and fiber material comprises the following steps:

[0038] Place the working interface of the OLED screen downwards in the mold, lay fiber material on the upper surface and sides of the OLED screen, pour the adhesive from above the composite fiber material layer through a vacuum infusion process, uniformly penetrate and then cure , so as to obtain an integrated structure of OLED screen body and fiber material, just take it out.

[0039] The fiber material is a mixture of carbon fiber and glass fiber, and the electrode area of the OLED screen is physically insulated from the fiber material.

[0040] As another embodiment, the fiber material includes alternately arranged carbon fiber cloth layers and chopped glass fiber mat layers, and the electrode area of the OLED screen is isolated from the carbon fiber cloth layers by the chopped glass fiber mat layers.

Embodiment 1

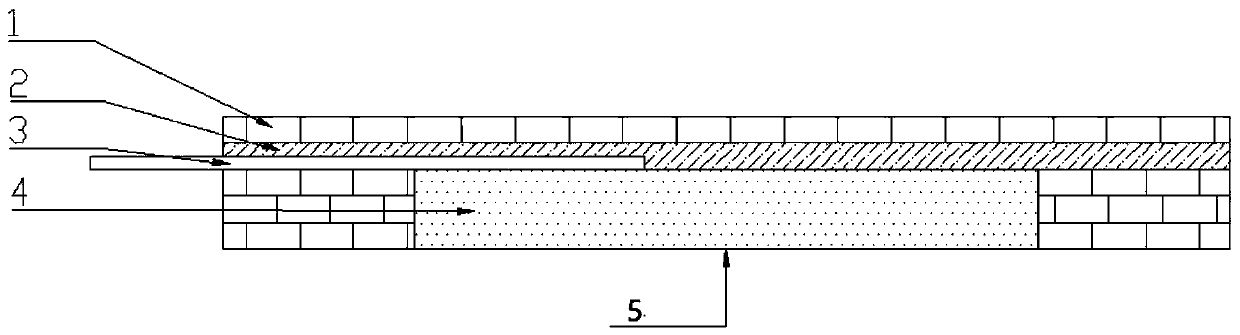

[0042] Such as figure 1 As shown, the present invention provides an integrated structure of an OLED screen body and a fiber material, including an OLED screen body and a protective shell covering the non-working interface of the OLED. In the pouring process, the binder is poured into the fiber material, and after curing, the fiber material and the OLED screen body 4 form an integrated structure.

[0043] The fiber material in this embodiment is composed of one layer of carbon fiber cloth layer 1 and one layer of chopped glass fiber mat layer 2, wherein the chopped glass fiber mat layer 2 is arranged on the non-working interface of the OLED screen body 4 and the carbon fiber cloth layer 1 In between, the electrode region 3 of the OLED screen is isolated from the carbon fiber cloth layer 1 by a chopped glass fiber mat layer 2 . Generally, there are two kinds of carbon fiber cloth layers: 0.111 mm and 0.167 mm. The thickness of the carbon fiber cloth layer used in this embodimen...

Embodiment 2

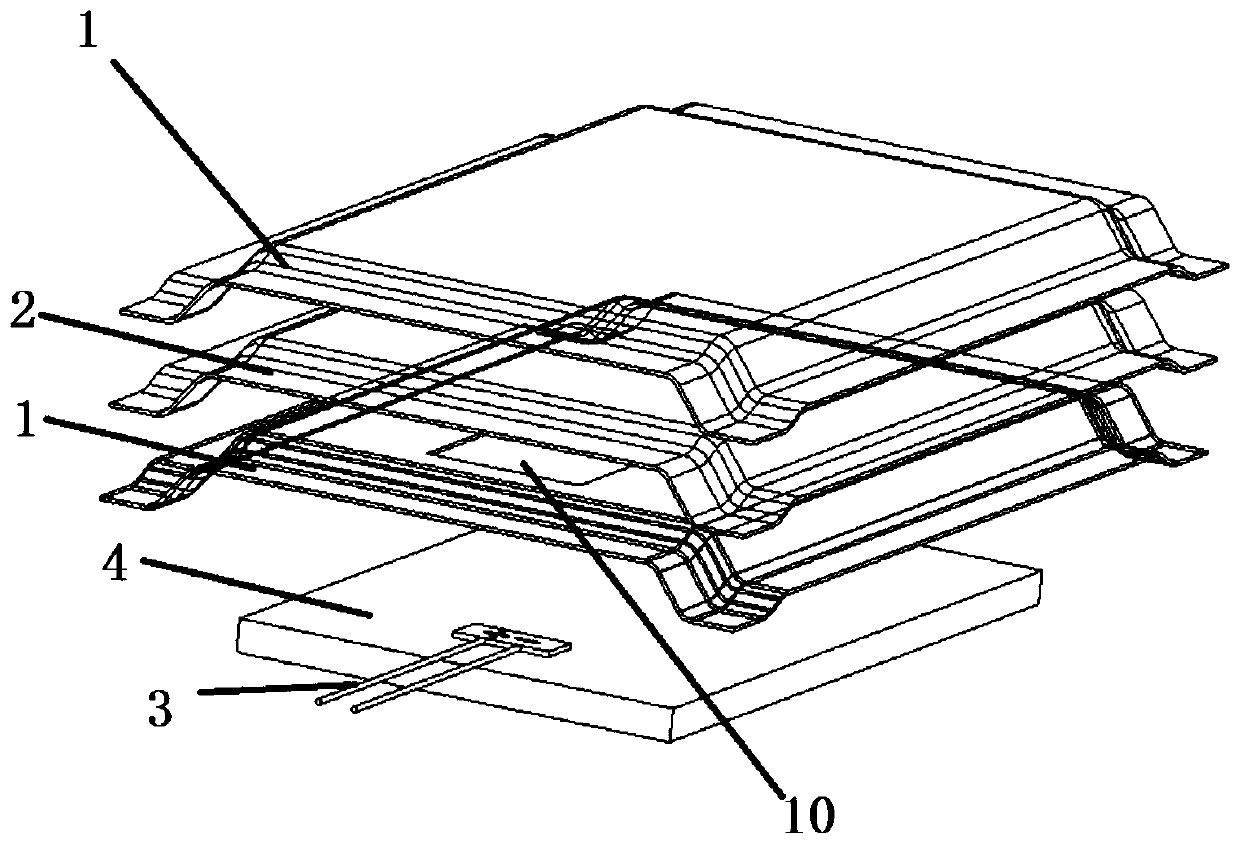

[0052] Such as image 3 As shown, the present invention provides an integrated structure of an OLED screen body and a fiber material, including an OLED screen body and a protective shell covering the non-working interface of the OLED. In the pouring process, the binder is poured into the fiber material, and after curing, the fiber material and the OLED screen body 4 form an integrated structure.

[0053] The fiber material of this embodiment is composed of a carbon fiber cloth layer 1, a chopped glass fiber mat layer 2 and a carbon fiber cloth layer 1 that are superimposed, wherein the carbon fiber cloth layer 1 that is in contact with the OLED screen body 4 is connected to the electrode area of the OLED screen body 4 (4) Cutouts are provided at the corresponding positions, and the electrode area (4) is not in contact with the carbon fiber cloth layer 1 so as to realize insulation. In this embodiment, the cloth layer of fiber material, the felt layer of fiber material, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com