A kind of cable tray for power line arrangement

A technology for cable trays and power lines, applied in the direction of electrical components, etc., can solve the problems of moisture corrosion, reduce the service life of cable trays, and the waterproofness of the bridge body and cables is not perfect, so as to avoid corrosion, improve work efficiency, and avoid cover The effect of plate fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

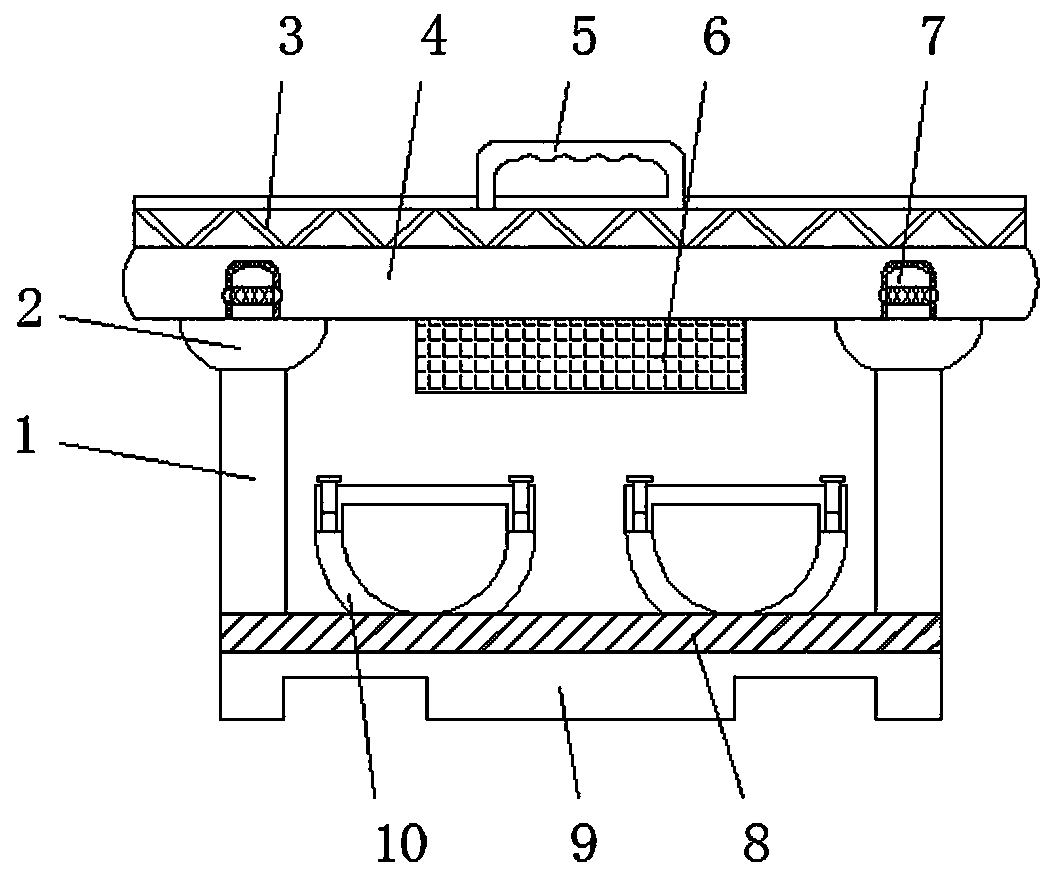

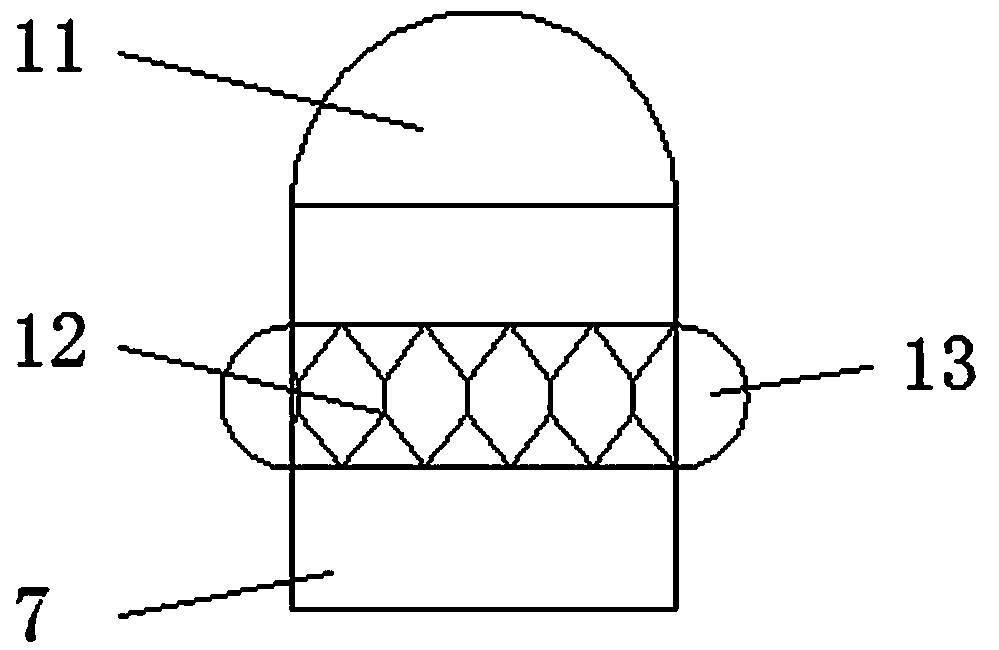

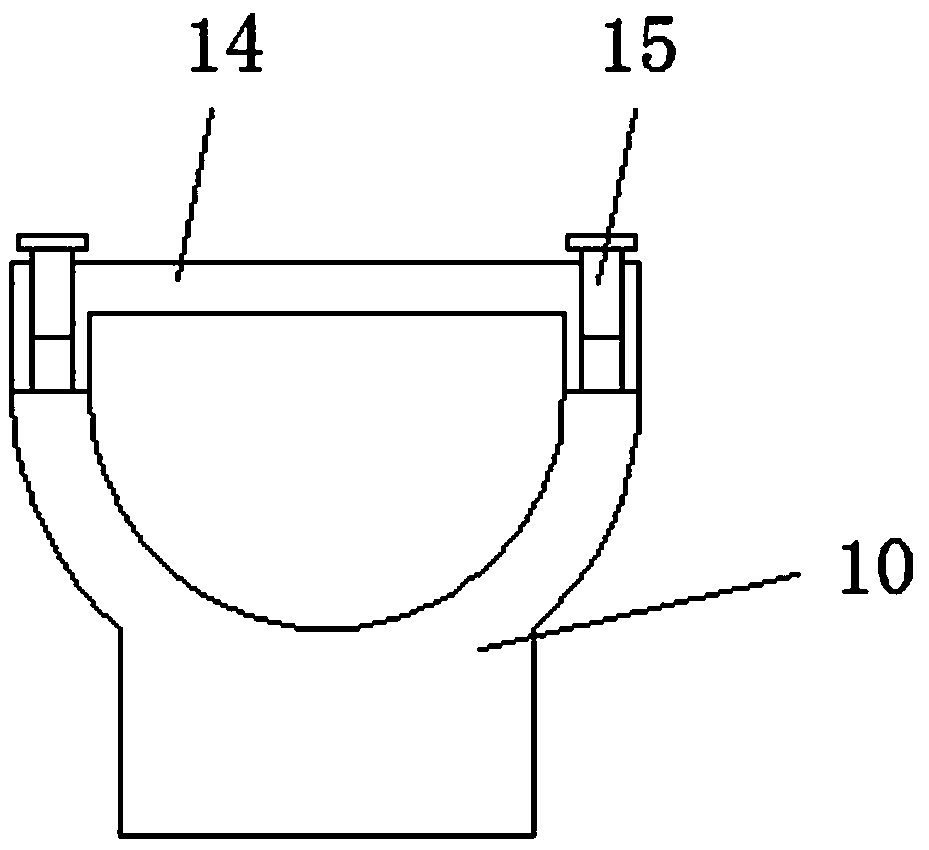

[0016] refer to Figure 1-3 , a cable bridge for power line wiring, including a bridge body 9, a moisture-proof board 8 is provided at the inner bottom of the bridge body 9, and a cable trough 10 is provided on the surface of the moisture-proof board 8, and a compression plate 14 is provided on the top of the cable trough 10 , and the inside of the pressing plate 14 is provided with a positioning pin 15, the side guard plate 1 is welded on both sides of the bridge body 9, and the pressure pad 2 is welded on the top of the side guard plate 1, and the pressure pad 2 is connected to the cover through the clamping column 7 The plates 4 are snap-connected, and a limit spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com