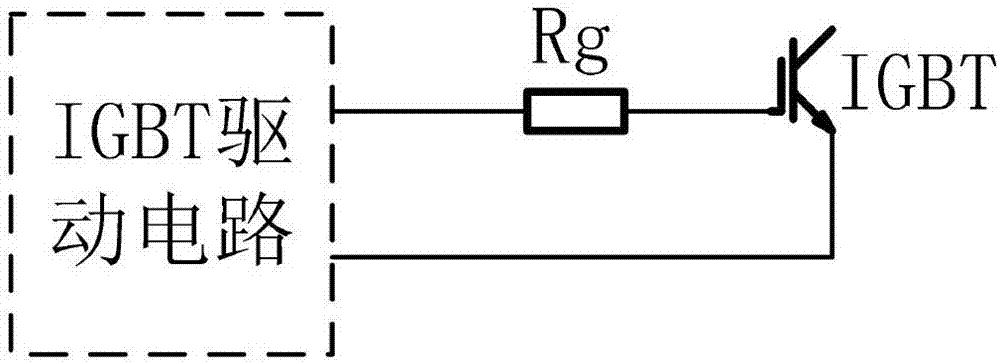

IGBT grid resistor variable circuit

A gate resistance and resistance technology, applied in the field of switching power supply, can solve problems such as unfavorable IGBT reliable shutdown, and achieve the effect of eliminating Miller effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with specific examples.

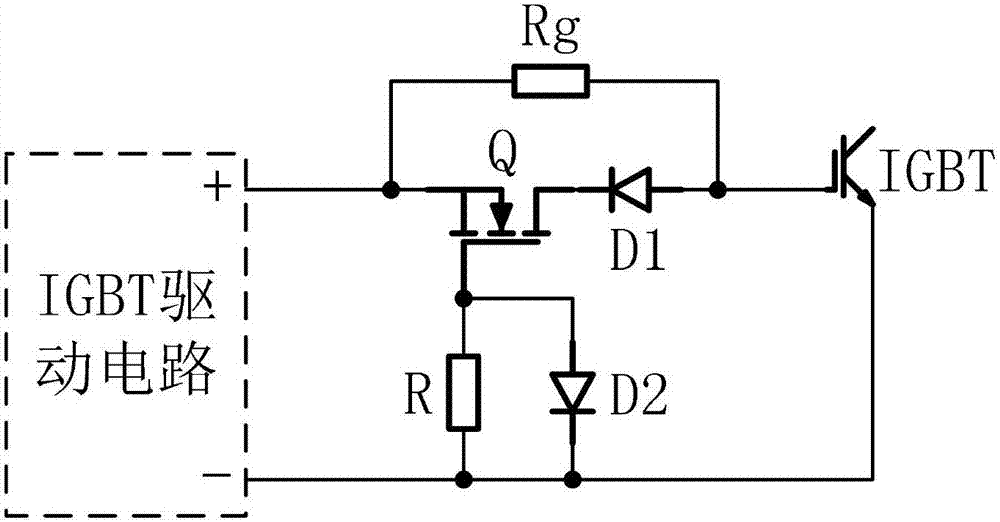

[0010] Such as figure 2 As shown, an IGBT gate resistance variable circuit according to an embodiment of the present invention includes an IGBT drive circuit, a first resistor Rg, a second resistor R, a first diode D1, a second diode D2, a field Effect tube Q and IGBT; the first resistor Rg is the IGBT gate resistor; the field effect tube Q is an N-channel enhancement type; the IGBT drive circuit outputs the drive voltage through the positive and negative terminals; the positive pole of the IGBT drive circuit and the first resistor Rg One end of the field effect transistor Q is connected to the source; the negative electrode of the IGBT drive circuit is connected to the emitter of the IGBT, one end of the second resistor R and the cathode of the second diode D2; the gate of the field effect transistor is connected to the second resistor The other end of R2 is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com