Method for estimating armature winding inductance of permanent magnet brushless motor

A permanent magnet brushless motor and armature winding technology, which is used in the control of generators, motor generators, and electromechanical brakes. , unable to improve the structure and other problems, to achieve the effect of optimal design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

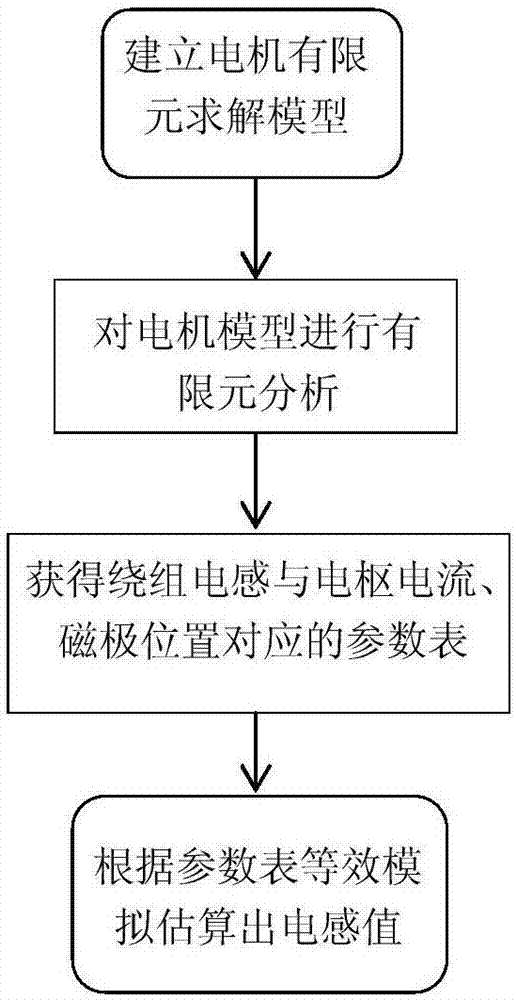

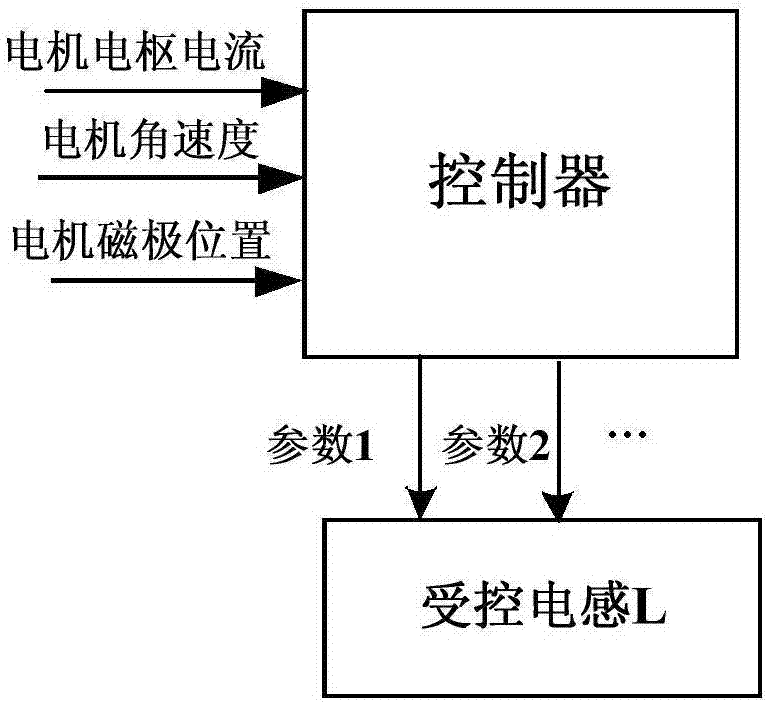

Method used

Image

Examples

Embodiment

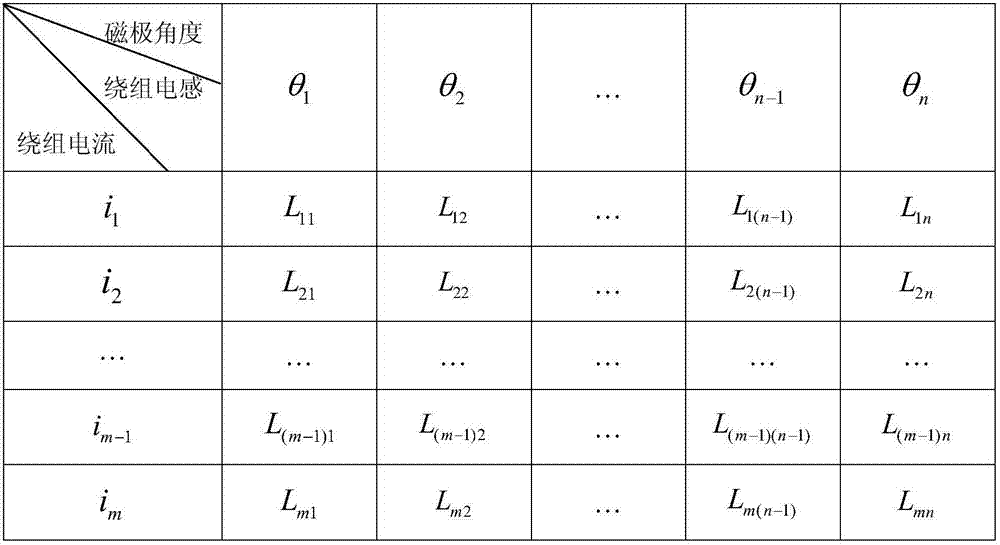

[0036] The armature current ranges from 0A to 10A, excluding 0A, and the step value is 0.5A; the magnetic pole angle ranges from 0° to 360°, and the step value is 15°; when the magnetic pole angle is 360°, It coincides with when the magnetic pole angle is 0°, so 360° is omitted.

[0037] A current of 0.5A is passed into the armature winding. When the magnetic pole angle is 0°, the winding inductance value at this time is calculated to be l 11 , change the magnetic pole position, when the magnetic pole angle is 15°, measure and calculate the winding inductance value at this time l 12 , and so on, calculate the winding inductance value l when the magnetic pole angle is 345° 1,24 .

[0038] Similarly, the armature winding is fed with a current of 1.0A. When the magnetic pole angle is 0°, the winding inductance value at this time is calculated to be l 21 , change the magnetic pole position, when the magnetic pole angle is 15°, measure and calculate the winding inductance value ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com