Double-layer PCB

A double-layer, flat part technology, applied in the direction of electrical connection of printed components, printed circuit components, etc., can solve the problems of cabinet performance degradation, moisture intrusion, ugly appearance, etc., and achieve high welding stability and low false soldering rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

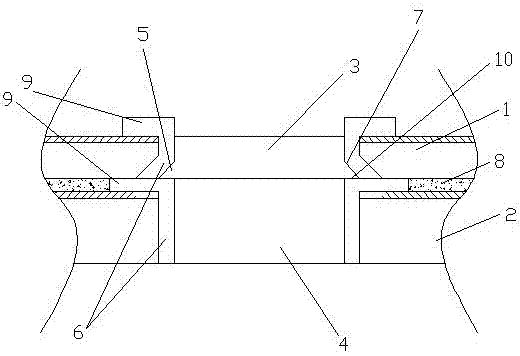

[0019] Such as figure 1 As shown, the embodiment of the present invention includes a first layer of board body 1 and a second layer of board body 2, the first layer of board body 1 is provided with a first via hole 3, and the second layer of board body 2 is provided at a position corresponding to the first via hole 3 There is a second via hole 4, and the junction of the first via hole 3 and the second via hole 4 is provided with a stagnant tin part 5 whose aperture diameter is larger than that of the first via hole 3 and the second via hole 4. The tin stagnation part 5 has at least There is a plane part 10 provided with the conductive material 6 , and the plane of the plane part 10 is parallel to the surface of the board body 1 . To the conductive substance 6 is a conductive copper foil layer. A conductive pad 9 and an insulating layer 8 are arranged between the two-layer board 2 and the side board, and the thickness of the insulating layer 8 is the same as that of the conduc...

Embodiment 2

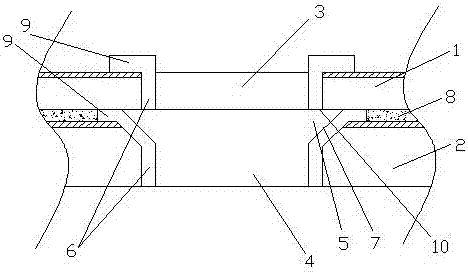

[0021] Such as figure 2 As shown, the embodiment of the present invention includes a first layer of board body 1 and a second layer of board body 2, the first layer of board body 1 is provided with a first via hole 3, and the second layer of board body 2 is provided at a position corresponding to the first via hole 3 There is a second via hole 4, and the junction of the first via hole 3 and the second via hole 4 is provided with a stagnant tin part 5 whose aperture diameter is larger than that of the first via hole 3 and the second via hole 4. The tin stagnation part 5 has at least There is a plane part 10 provided with the conductive material 6 , and the plane of the plane part 10 is parallel to the surface of the board body 1 . To the conductive substance 6 is a conductive copper foil layer. A conductive pad 9 and an insulating layer 8 are arranged between the two-layer board 2 and the side board, and the thickness of the insulating layer 8 is the same as that of the condu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap