Bypass heat shield element

A technology of heat shielding and components, used in gas turbine installations, linings of combustion chambers, and annular combustion chambers, which can solve problems such as high pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

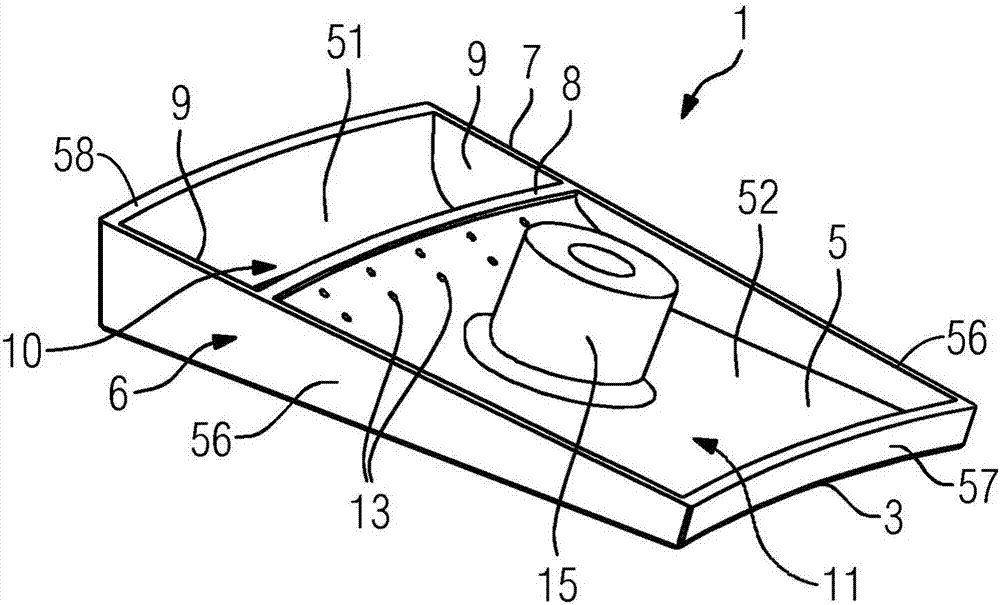

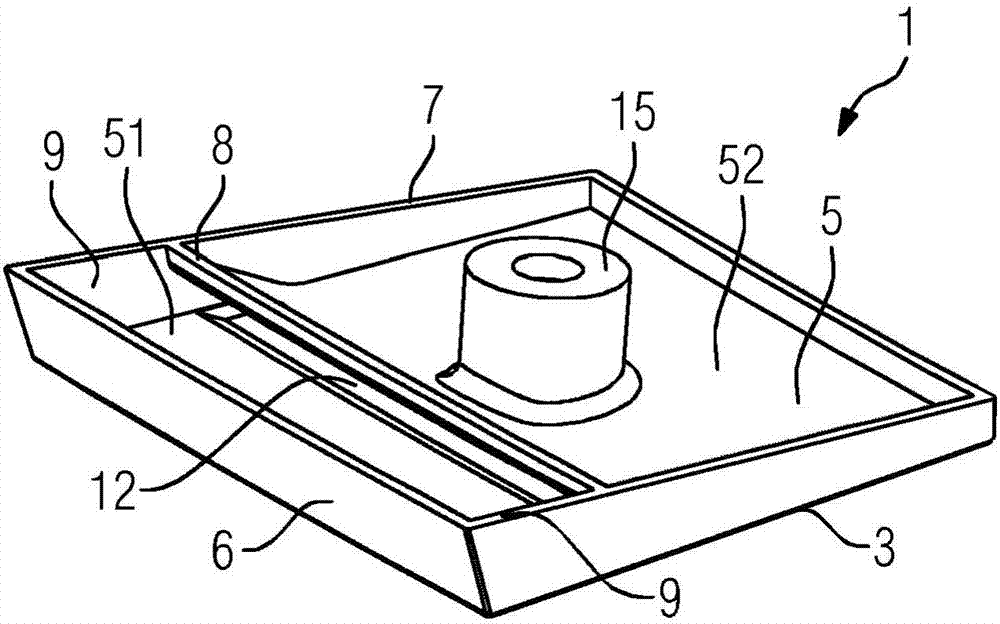

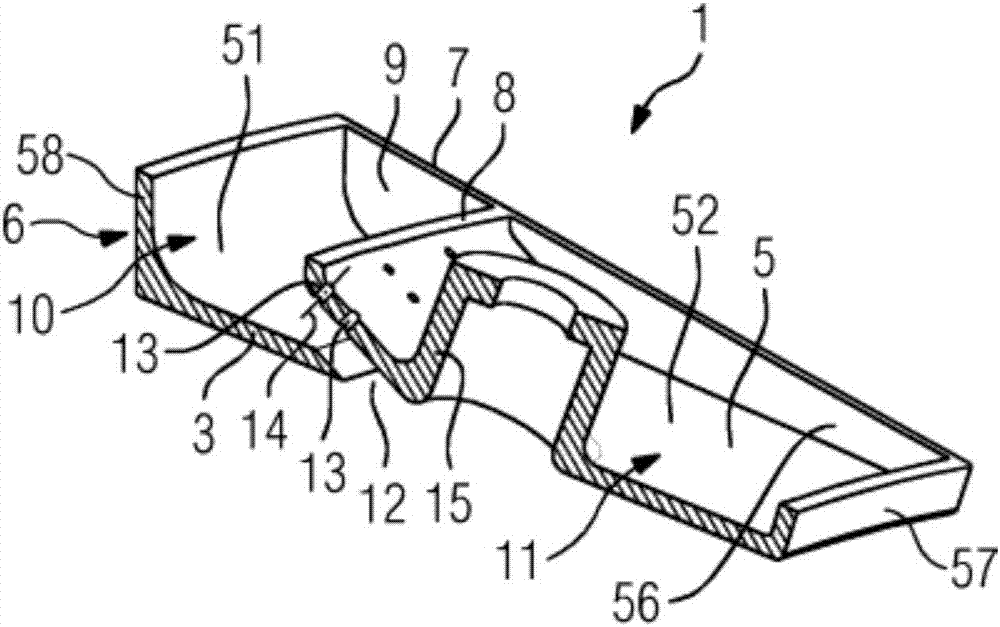

[0037] Figures 1 to 4 A metallic heat shield element 1 according to the invention is shown schematically and by way of example, having a wall 3 with a hot side 4 to which a heat medium can be applied and a cold side 5 opposite the hot side 4 . Figures 1 to 3 shows the cold side 5, Figure 4 The hot side 4 is shown.

[0038] A peripheral edge 6 , which extends beyond the cold side 5 and has a free end 7 facing away from the cold side 5 , adjoins the wall 3 . Here, the wall comprises two opposite first edge sections 56 and a second edge section 57 extending transversely to the two first edge sections 56 and opposite to the second edge sections 57 . Set the third edge section 58. Between the two opposite sides 9 formed by the edge 6, the partition 8 extends from the cold side 5 of the wall 3 up to the level of the free end 7, so that on the cold side 5 of the wall 3 two separate A first chamber 10 and a second chamber 11 , and the first chamber 10 has an open gap 12 from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com