A kind of photovoltaic cell and its manufacturing method

A photovoltaic cell and battery technology, applied in the direction of photovoltaic power generation, circuits, electrical components, etc., can solve problems such as gaps, lower open circuit voltage and fill factor, and low battery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

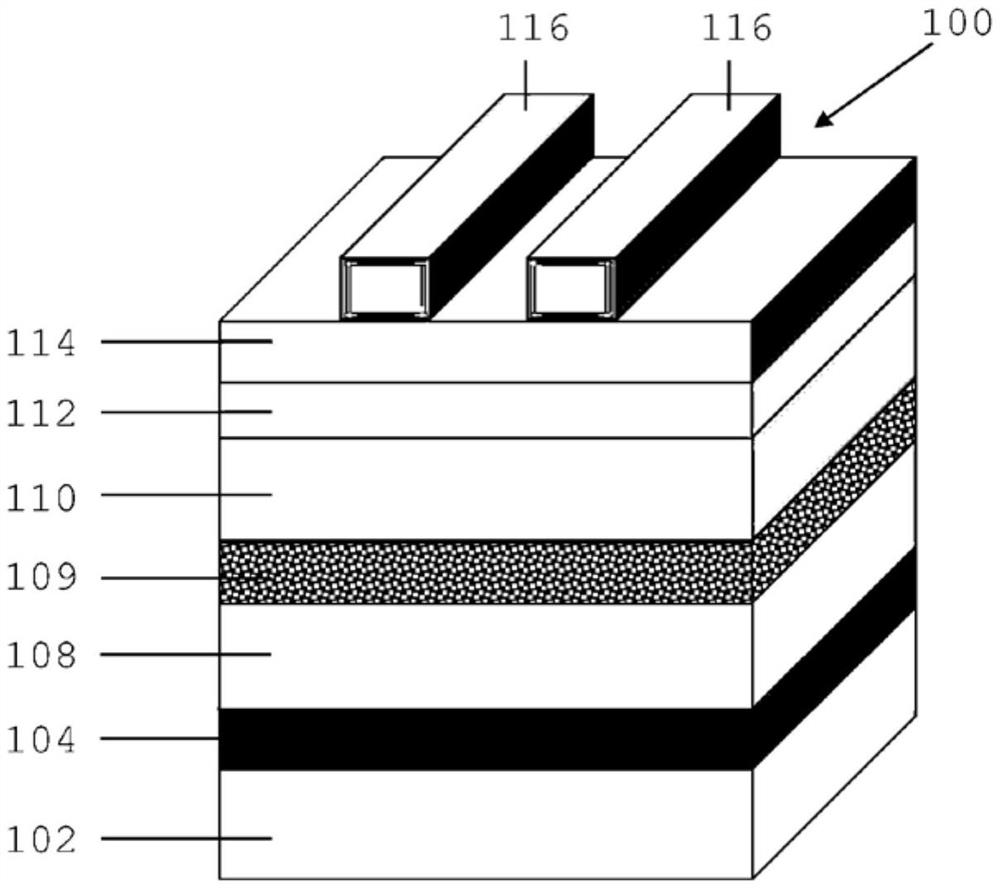

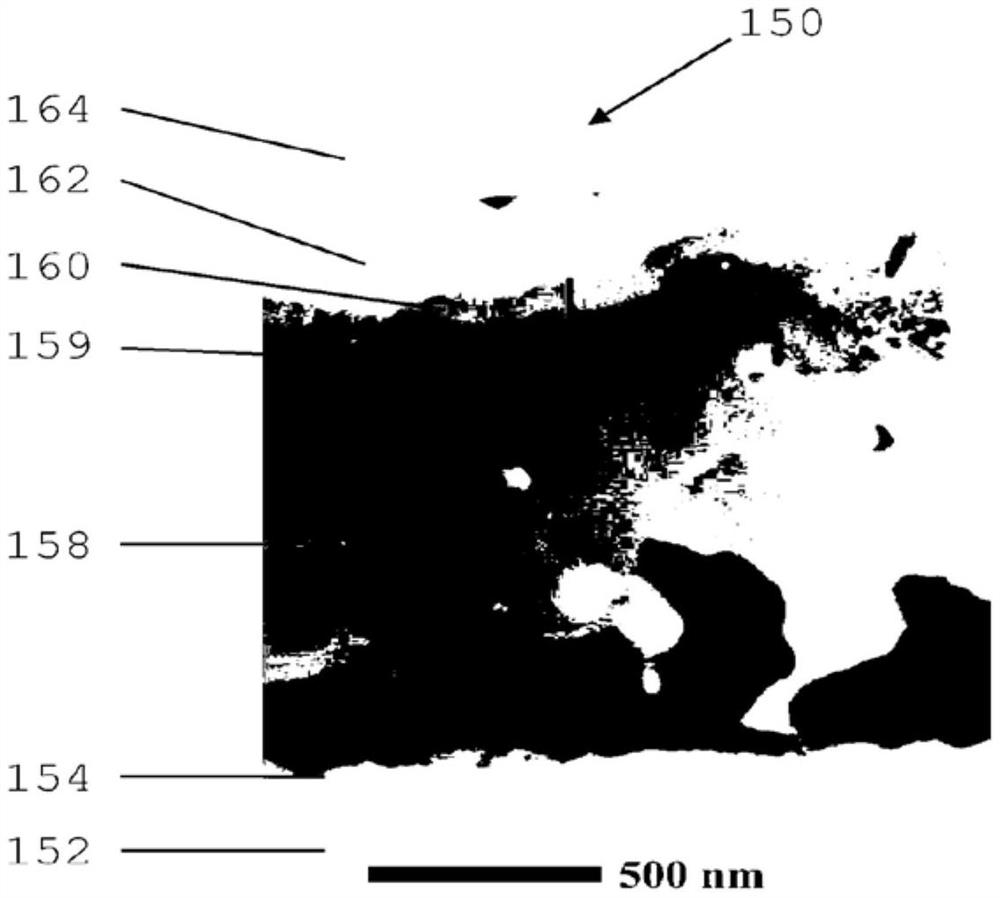

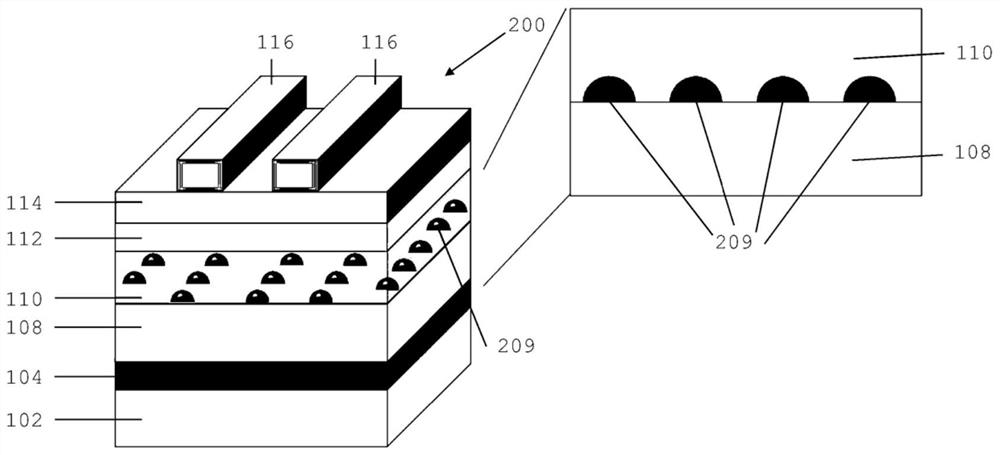

[0074] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

[0075] Embodiments of the present invention relate to photovoltaic cells having copper-based light absorbing materials such as copper zinc tin sulfur absorber layers, cadmium sulfide, and metal electrodes. In particular, embodiments of the present invention relate to photovoltaic cells of various configurations with an interlayer material between the light absorbing material and the cadmium sulfide. Photovoltaic cells can be deposited on glass substrates, stainless steel, flexible polyimide, or metal foils.

[0076] In certain embodiments, the interlayer material reduces recombination of photogenerated carriers at the copper-zinc-tin-sulfur / cadmium-sulfide interface by passivating the first surface of the light-absorbing layer portion. The recombination of photogenerated carriers is minimized in the passivated part. A P-n junction is formed on the second sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| external quantum efficiency | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| external quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com