Lithium-ion secondary-battery case and manufacturing method therefor

A secondary battery and manufacturing method technology, applied in the direction of secondary batteries, battery boxes/coats, manufacturing tools, etc., can solve problems such as electrolyte leakage, and achieve the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

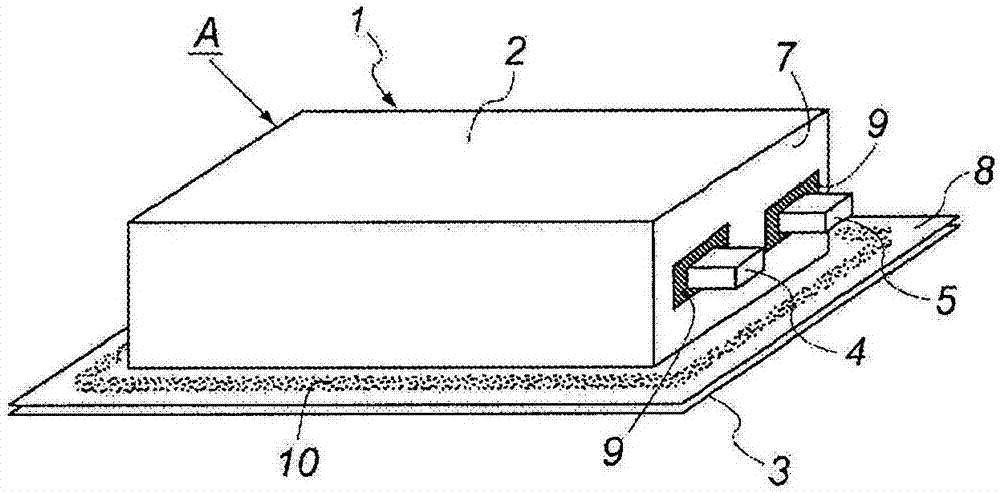

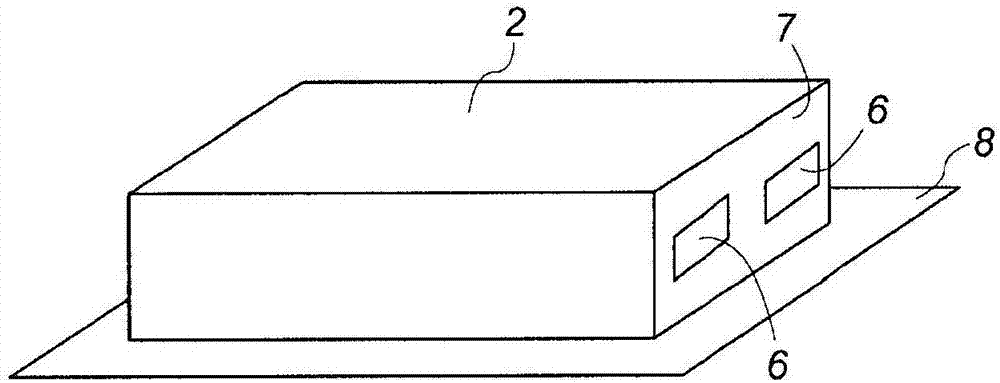

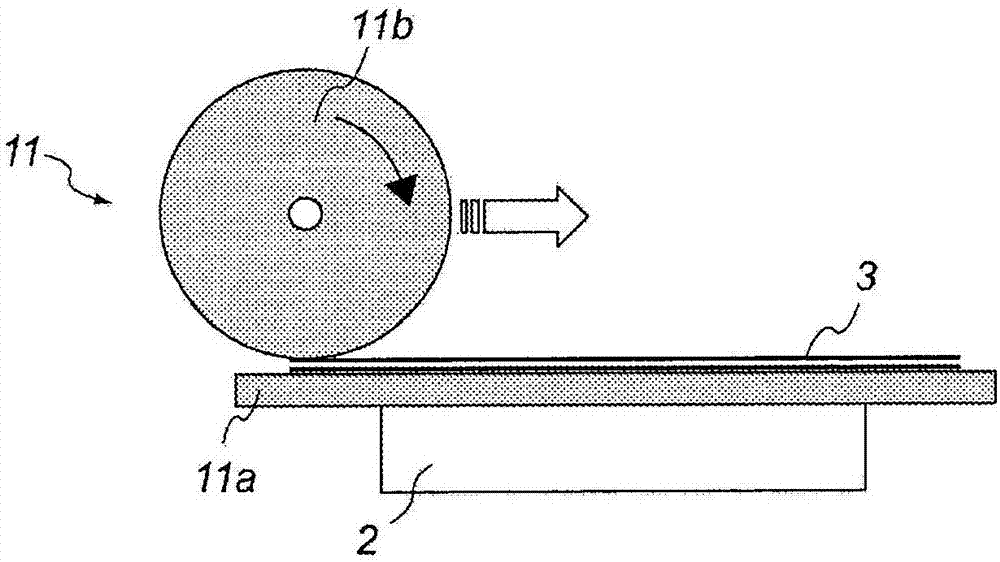

[0036] figure 1 is a schematic diagram of a case 1 for a lithium ion secondary battery according to an embodiment of the present invention, figure 2 It is the cup member 2 which comprises the case 1 for lithium ion secondary batteries mentioned above. The cup member 2 is a cup-shaped member that is punched out of austenitic stainless steel foil as a raw material, and is further penetrated with holes 6 for leading out electrode terminals 4 and 5 . By diffusion bonding this to the lid member 3 , the case 1 for a lithium ion secondary battery is formed. It should be noted that the details will be described later, but in the illustrated embodiment, the hollow hole 6 is provided in the vertical wall portion 7 of the cup member 2 .

[0037] The cup member 2 and the lid member 3 use stainless steel foil as a raw material. The stainless steel foil used for the cup member 2 is an austenitic stainless steel foil because it involves pressing.

[0038] On the other hand, the stainles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com