Multi-functional shoeing cutter disc

A hoof trimming knife and multi-functional technology, which is applied in the fields of medical science, metal processing, veterinary instruments, etc., can solve the problems of inability to use electric tools, large labor for hoof trimming, and high hoof trimming cost, and achieves reasonable and novel structural design. , The effect of reducing workload and saving working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

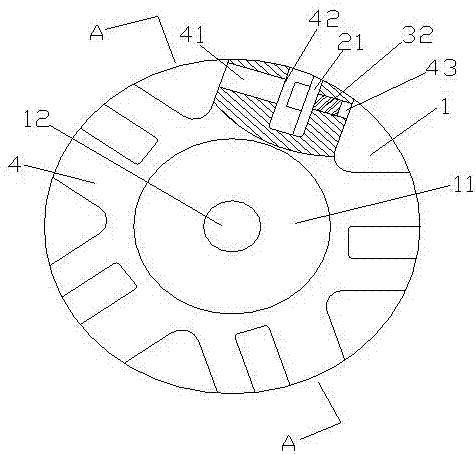

[0020] As shown in the figure, the present invention is a multifunctional hoof trimming cutter head, including a cutter head body (1), on which several blade groups are fixedly arranged; the cutter head body (1) is circular The disc body, the middle part of the cutter head body (1) is provided with a settling tank (11), and the middle part of the settling tank (11) is provided with a fixing through hole (12); the blade set includes a blade (21) and a blade fixing assembly, the blade (21) It is set perpendicular to the upper end surface of the cutter head body (1) and the blade end of the blade (21) protrudes from the upper end surface of the cutter head body (1). Several blade group fixing grooves are arranged on the cutter head body (1). (21) and the blade fixing component are arranged in the blade group fixing groove body, and the blade (21) is fixedly connected with the blade group fixing groove body through the blade fixing component.

[0021] The blade fixing assembly inc...

Embodiment 2

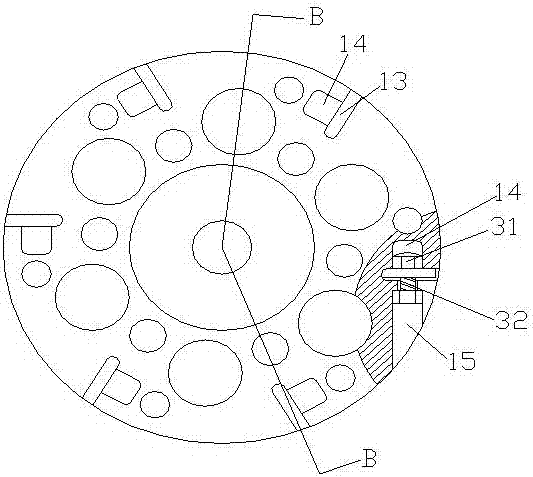

[0024] The difference between this embodiment and Embodiment 1 is that the blade fixing assembly includes a screw (32) and a fixing piece (31), and the blade group fixing groove body includes a through groove (15), a blade groove (13) and a blade fixing Groove (14), one end opening of the through groove (15) is arranged on the side wall of the cutterhead body (1), and the other end opening of the through groove (15) is arranged on the inner side wall of the blade groove (13); the blade (21 ) is set in the blade groove (13), the fixed piece (31) is set in the blade fixed groove (14), the screw (32) passes through the blade (21) and is threadedly connected with the fixed piece (31), the screw (32) One end is arranged in the through groove (15), and the length extension direction of the through groove (15) is arranged parallel to the upper end surface of the cutterhead body (1). The fixed piece (31) is a nut, and the fixed piece (31) and the blade (21) are fixedly welded.

[002...

Embodiment 3

[0028] The difference between this embodiment and Embodiment 1 and Embodiment 2 is that the blade fixing assembly includes a fixing piece (31) and a fixing screw (32), and the blade group fixing groove body includes a blade groove (13) and a blade fixing groove (14 ), the fixed piece (31) is fixedly connected with the blade (21), the blade (21) is set in the blade groove (13), the fixed piece (31) is set in the blade fixing groove (14), and the fixing screw (32) passes through The inner bottom end surface of the blade fixing groove (14) is threadedly connected with the fixing piece (31), and the fixing screw rod (32) is vertically arranged with the upper end surface of the cutter head body (1).

[0029] The fixed piece (31) is integrally formed with the blade (21), and the fixed piece (31) is perpendicular to the blade (21).

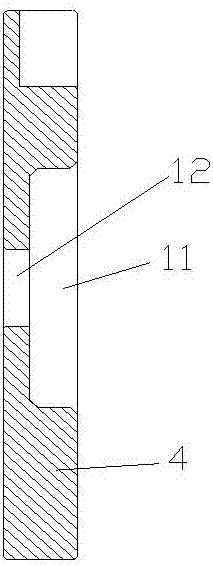

[0030] Since the cutter body (1) needs to be inserted between the fingers of the two toes of the hoof for hoof trimming, the thickness of the cutter bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com