Transmission drum with surface covered with ceramic

A transmission roller and ceramic technology, applied in the direction of conveyor objects, transportation and packaging, rollers, etc., can solve the problems of complex structure of the transmission roller, poor anti-wear and anti-skid, troublesome maintenance and replacement, etc., to achieve simple and practical production, Good anti-skid effect, not easy to move relative to each other

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

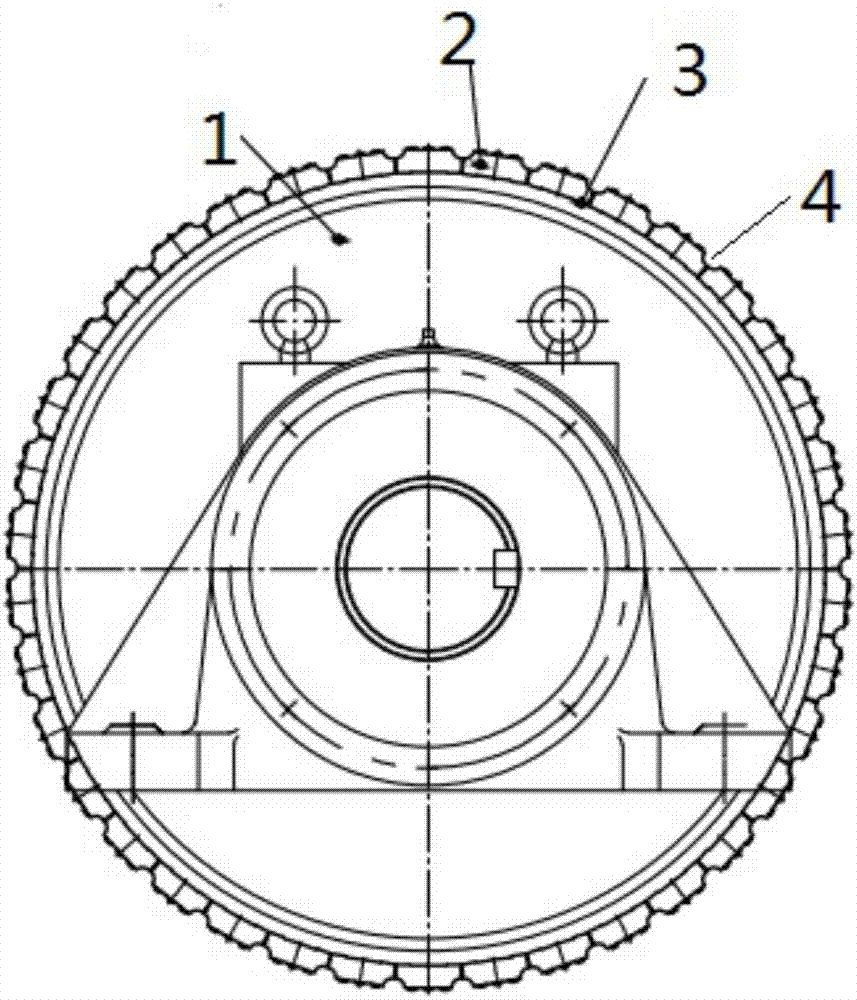

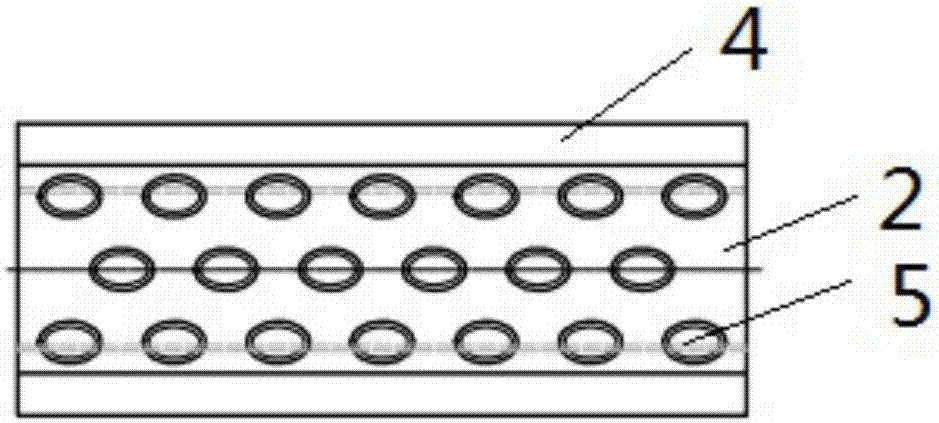

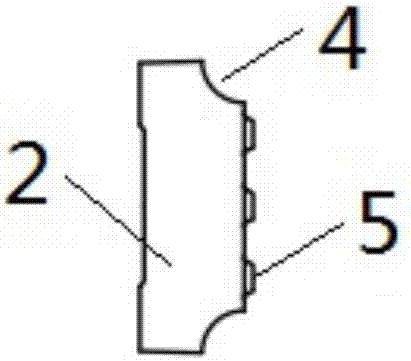

[0023] Such as figure 1 The structure schematic diagram of the drive roller that the surface provided by the present invention is covered with ceramics, figure 2 Schematic diagram of the structure of the anti-corrosion and wear-resistant parts provided by the present invention, image 3 Structural schematic diagram and Figure 4 As shown in the structural diagram of the drive roller covered with ceramics provided by the present invention, the drive roller covered with ceramics provided by the present invention is characterized in that it includes a drive roller body 1 with grooves on the surface and is installed on the The anti-wear and anti-skid component 2 in the groove, the anti-wear and anti-skid component 2 includes high-strength ceramic sheets, and the high-strength ceramic sheets are arranged in dislocation in the groove;

[0024] The upper surface of the high-strength ceramic sheet has bumps 5, and a high-strength adhesive layer 3 is provided between the lower surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com