Piston type vacuum coaxial valve with vacuum as power air source

A technology of piston valves and coaxial valves, which is applied in the direction of valve details, valve devices, engine components, etc., to achieve the effect of high operation control cost, low power consumption, and convenient and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

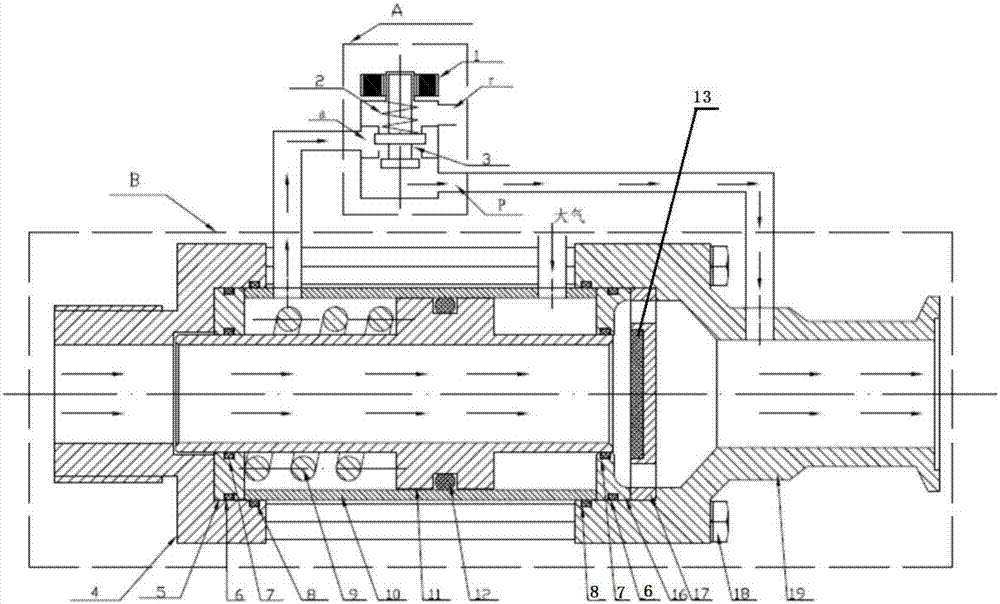

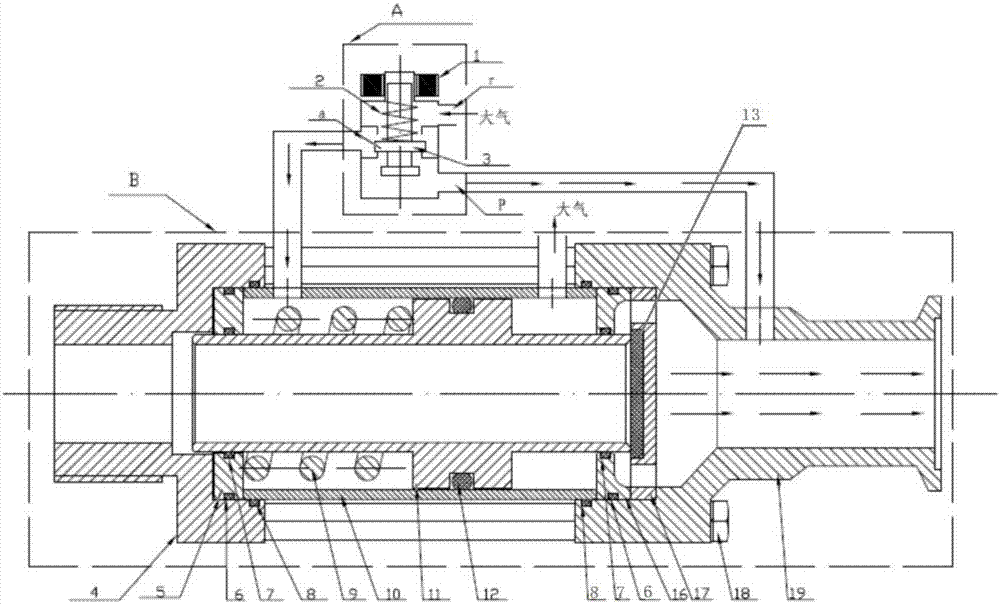

[0028] Such as figure 1 and figure 2 As shown, a piston-type vacuum coaxial valve with vacuum as a power source includes a solenoid valve part A and a coaxial valve part B: the solenoid valve part includes an electromagnetic control device; the coaxial valve part uses vacuum as a power source, including Piston type spool 11, cylinder barrel 10, left pressing block 4, right pressing block 19, left sealing block 5, right sealing block 16, sealing ring, sealing valve seat 17. Wherein, the piston type spool 11 is cylindrical, is set in the cylinder barrel 10 and can realize reciprocating movement; the two ends of the cylinder barrel 10 are equipped with sealing blocks, one on the left and one on the left, which are respectively the left sealing block 5 and the right sealing block 16, The sealing block is used to seal the gap between the piston valve core and the cylinder barrel; the outer end of the sealing block is also equipped with pressing blocks, one on the left and one on ...

Embodiment 2

[0039] refer to figure 1 and figure 2 As shown, a piston-type vacuum coaxial valve with vacuum as the power source includes a solenoid valve part and a coaxial valve part: the solenoid valve part includes an electromagnetic control device; the coaxial valve part uses vacuum as a power source, including a piston type Spool 11, cylinder barrel 10, left pressing block 4, right pressing block 19, left sealing block 5, right sealing block 16, sealing ring, sealing valve seat 17. Wherein, the piston type spool 11 is cylindrical, is set in the cylinder barrel 10 and can realize reciprocating movement; the two ends of the cylinder barrel 10 are equipped with sealing blocks, one on the left and one on the left, which are respectively the left sealing block 5 and the right sealing block 16, The sealing block is used to seal the gap between the piston valve core and the cylinder barrel; the outer end of the sealing block is also equipped with pressing blocks, one on the left and one on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com