Liriodendron tulipifera hardwood cutting method

A technology of hard branch cutting and Liriodendron, applied in the field of plant breeding, can solve the problems of short sterilization time, failure, low survival rate of cuttings, etc., and achieve the effect of fast rooting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

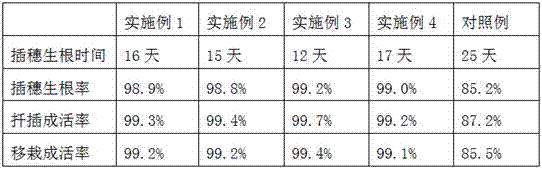

Examples

Embodiment 1

[0030] Example 1 A kind of antiseptic cutting substrate

[0031] Weigh the following antiseptic cutting matrix components: 10 parts by weight of perlite, 5 parts by weight of vermiculite, 3 parts by weight of jute, 2 parts by weight of raw land, 2 parts by weight of cork, 2 parts by weight of oyster shells, 30 parts by weight of peat soil, elm bark 20 parts by weight of powder, stirred and mixed, sprayed with an appropriate amount of water, and stirred while spraying, so that the water content of the substrate was 32%, and the antiseptic cutting substrate can be obtained.

Embodiment 2

[0032] Embodiment 2 A kind of antiseptic cutting matrix

[0033] Weigh the following anti-corrosion cutting matrix components: 15 parts by weight of perlite, 9 parts by weight of vermiculite, 4 parts by weight of jute, 4 parts by weight of raw land, 3 parts by weight of cork, 5 parts by weight of oyster shells, 40 parts by weight of peat soil, elm bark 30 parts by weight of powder, stir and mix, spray appropriate amount of water, and stir while spraying, so that the water content of the substrate is 35%, and the antiseptic cutting substrate can be obtained.

Embodiment 3

[0034] Embodiment 3 A kind of antisepsis cuttage matrix

[0035] Weigh the following anti-corrosion cutting matrix components: 12 parts by weight of perlite, 6 parts by weight of vermiculite, 3.5 parts by weight of jute, 3 parts by weight of raw land, 2.5 parts by weight of cork, 4 parts by weight of oyster shells, 36 parts by weight of peat soil, elm bark Powder 27 parts by weight, stir and mix, spray appropriate amount of water, and stir while spraying, so that the water content of the substrate is 33%, and the antiseptic cutting substrate can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com