Liquid separation structure used for tubular centrifuging machine

A technology of tubular centrifuge and inclined structure, applied in centrifuges and other directions, can solve the problems of small drum volume, low separation efficiency, intermittent operation, etc., and achieve the effects of saving energy consumption, efficient liquid separation, and improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

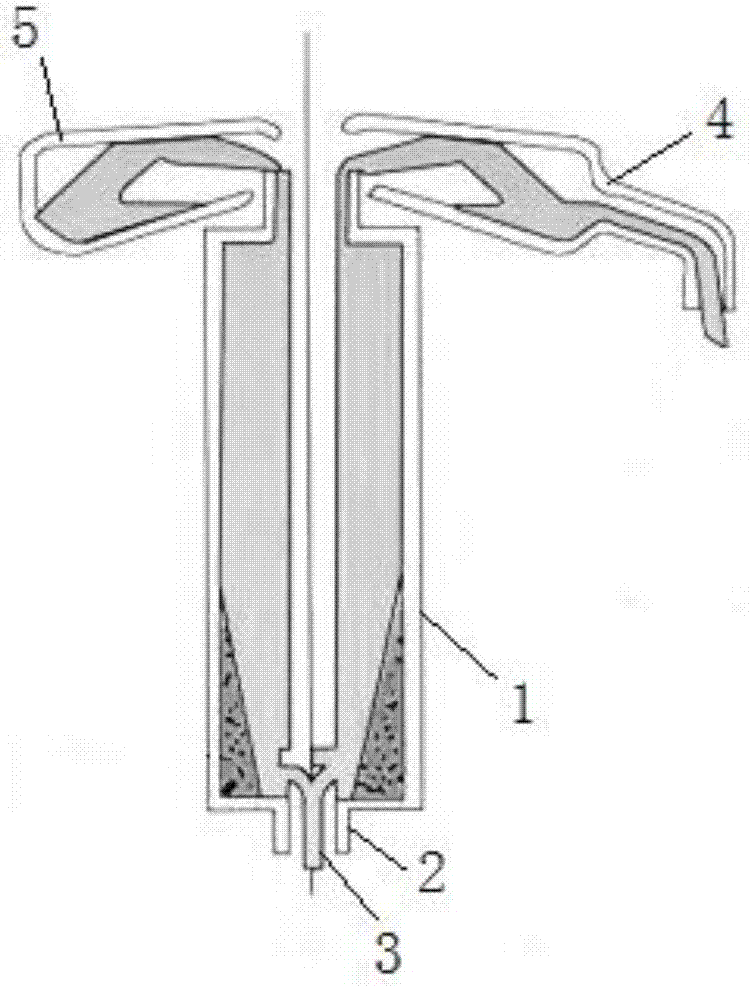

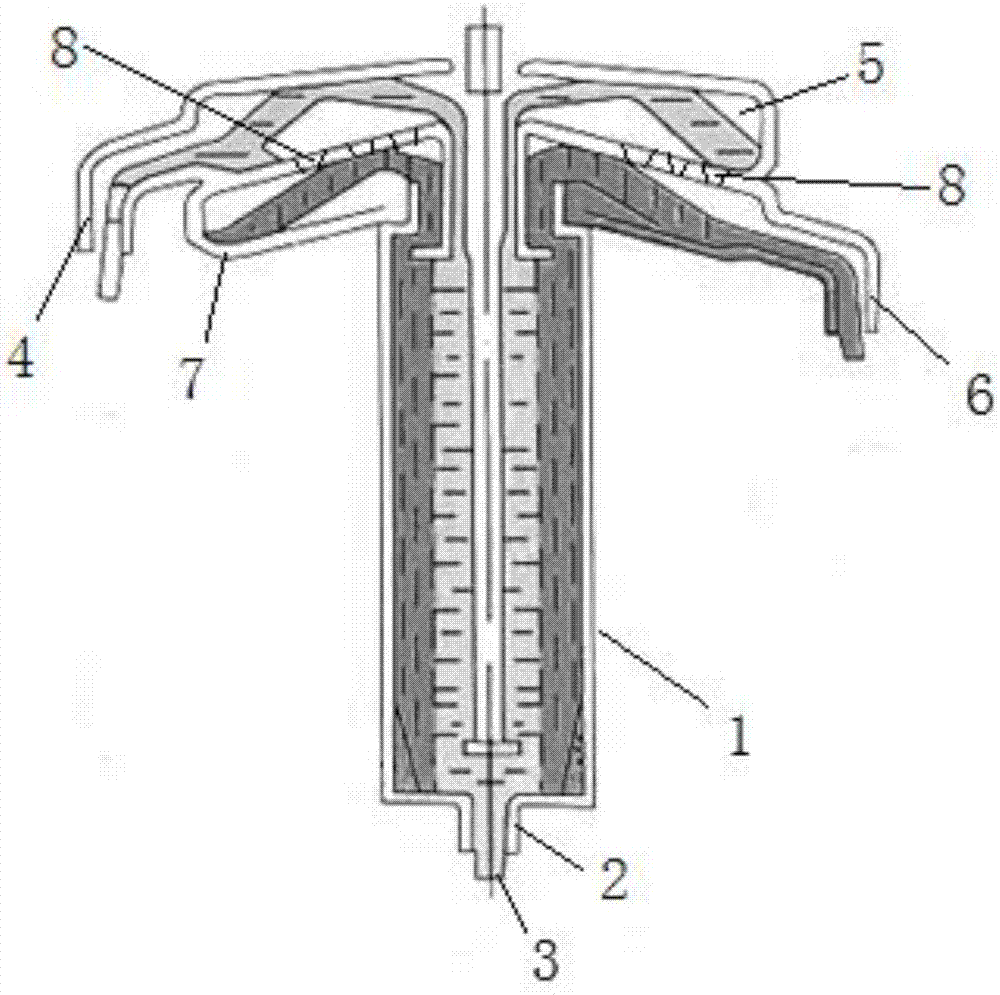

[0016] Such as figure 1 and figure 2 The shown liquid separation structure for a tubular centrifuge includes a liquid collection tray 1, a support sleeve 2 arranged under the liquid collection tray 1, a liquid inlet 3 arranged in the support sleeve 2, and a set The light liquid outlet 4 on the liquid collection tray 1 and connected to the liquid collection tray 1, and the light liquid return cavity 5 arranged on the liquid collection tray 1 and connected to the liquid collection tray 1, wherein the light liquid outlet 4. Between the light liquid return chamber 5 and the liquid collecting tray 1 is a downwardly inclined structure.

[0017] Further preferably, the liquid separation structure for the tubular centrifuge also includes a heavy liquid outlet 6 arranged on the liquid collection tray 1, and a heavy liquid outlet 6 arranged on the liquid collection tray 1 and connected to the liquid collection tray 1. The return chamber 7, wherein the light liquid outlet 4 and the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com