High-precision controllable mechanism type welding robot with multiple degrees of freedom

A welding robot, high-precision technology, applied in the field of machinery, can solve the problems of easy to generate large vibration, poor dynamic performance of the robot, large mass and volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

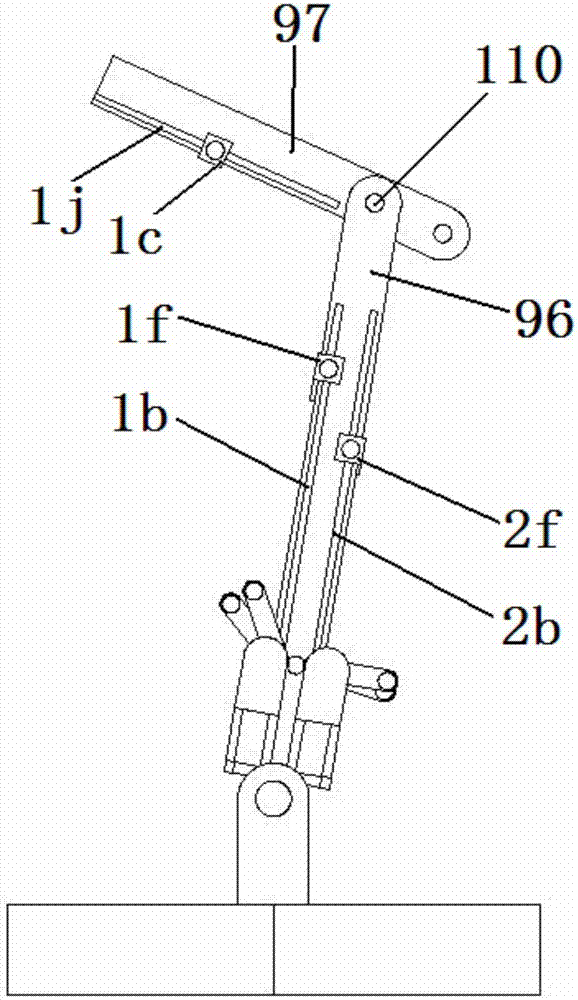

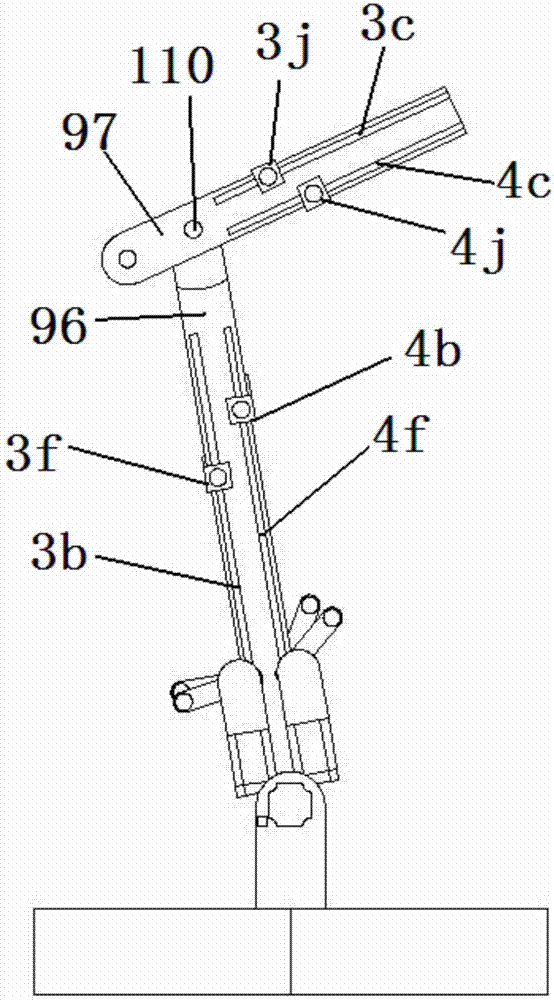

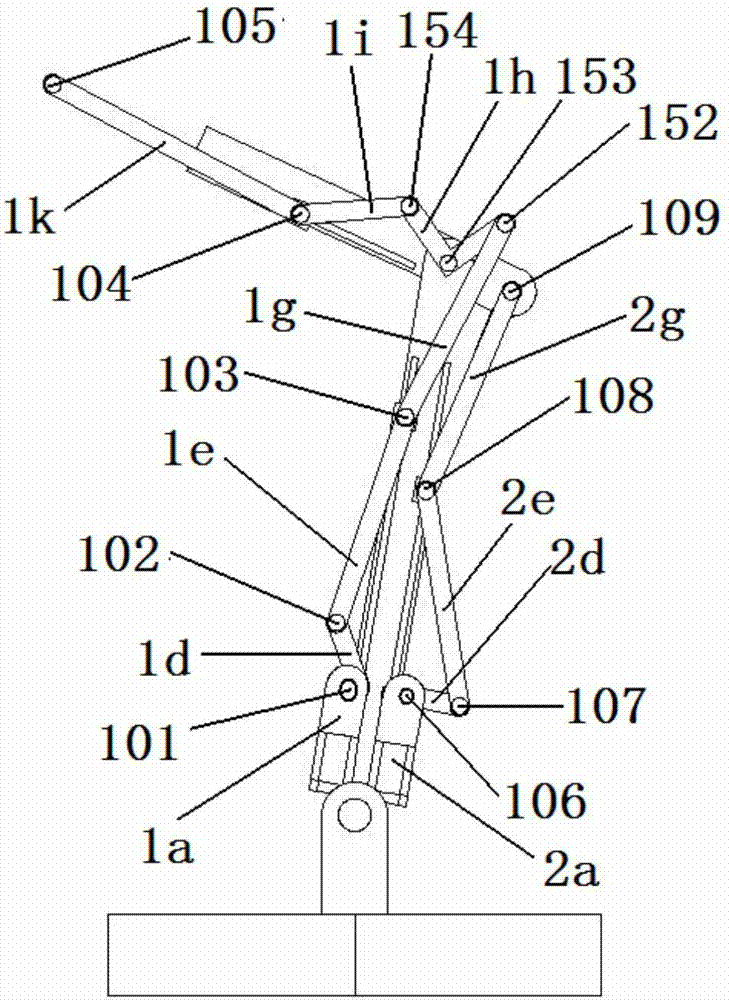

[0143] A multi-degree-of-freedom high-precision controllable mechanism welding robot, the first primary chute 1b, the second primary chute 2b, the third primary chute 3b, the fourth primary chute 4b, the first active rod 1d, the second Active lever 2d, third active lever 3d, fourth active lever 4d, first primary driven lever 1e, second primary driven lever 2e, third primary driven lever 3e, fourth primary driven lever 4e, first Primary slider 1f, second primary slider 2f, third primary slider 3f, fourth primary slider 4f, first secondary driven lever 1g, second secondary driven lever 2g, third secondary driven Rod 3g, 4th secondary follower rod 4g, 1st secondary chute 1c, 3rd secondary chute 3c, 4th secondary chute 4c, 1st secondary slider 1j, 3rd secondary slider 3j, the fourth secondary slider 4j, the first final driven rod 1k, the third final driven rod 3k, the fourth final driven rod 4k, the first and third driven rod 1i, the third and third Driven rod 3i, fourth and thir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com