Rapid-disassembly batching device with telescopic batching roller

A cloth roll and cloth rolling technology, which is applied in the field of textile rolling, can solve unreasonable and cumbersome problems, and achieve the effect of improving work efficiency and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

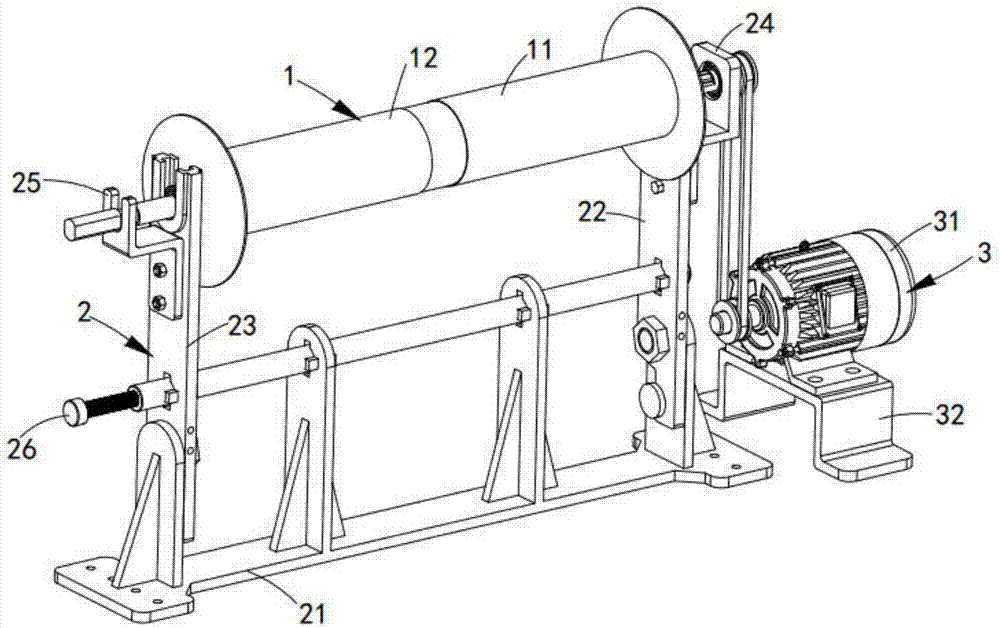

[0047] Such as figure 1 and figure 2 As shown, a retractable and quick-release cloth rolling device for the cloth rolling roller, including:

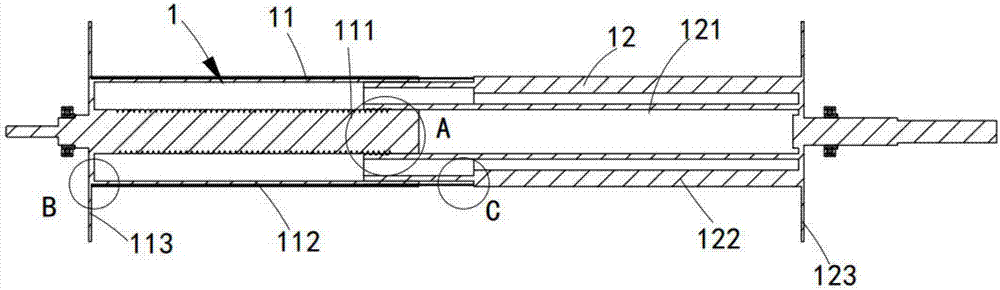

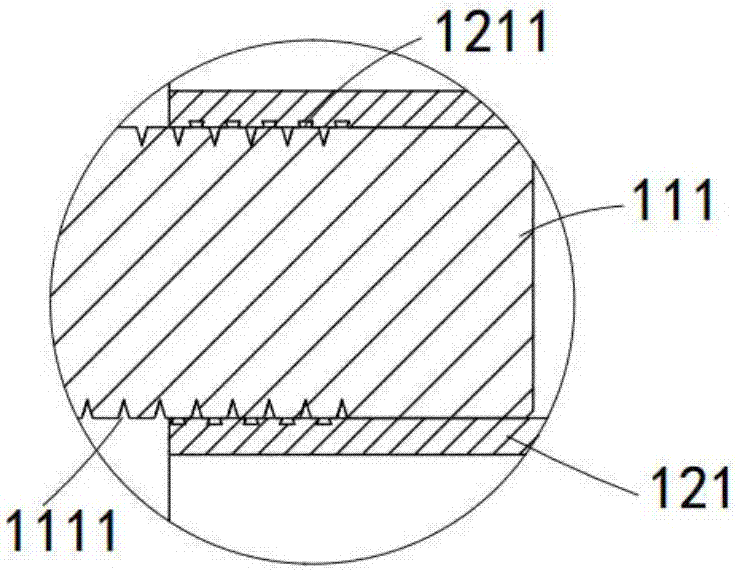

[0048] Cloth rolling roller 1, the cloth rolling roller 1 includes a first roller 11 and a second roller 12, and the first roller 11 and the second roller 12 respectively pass through the first main shaft 111 and the second main shaft 121 Concentric sliding socket;

[0049] Frame 2, the frame 2 is used to support the cloth rolling roller 1, it includes a base 21, and a first bracket 22 and a second bracket 23 respectively symmetrically hinged on both sides of the base 21, and it also includes a The driving mounting plate 24 fixedly connected to the first bracket 22 and the limiting plate 25 fixedly connected to the second bracket 23;

[0050] The driving assembly 3, the driving assembly 3 is arranged on one side of the frame 2, which is located on one side of the first roller 11, and drives the first roller 11 to rotate, and drives th...

Embodiment 2

[0074] Figure 11 It is a structural schematic diagram of Embodiment 2 of a retractable and quick-release cloth rolling device of the present invention; Figure 11 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. This embodiment two and figure 1 The difference of the shown embodiment one is:

[0075] like Figure 11 As shown, a retractable and quick-release cloth roll device also includes a transfer trolley 4, which is arranged parallel to the length direction of the frame 2, and is used to transfer rolled textiles.

[0076] It should be noted that after the cloth roll 1 has finished winding the cloth, the positioning roller 26 is pulled out, the first bracket 22 and the second bracket 23 are rotated so that the cloth roll 1 is placed on the transfer tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com