Rebar spacing adjuster

A technology of steel bar spacing and adjuster, which is applied in construction, building structure, construction material processing and other directions, can solve problems such as affecting construction progress, unsatisfactory results, and missed work and time, and achieves easy operation, simple structure, and easy manufacturing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing:

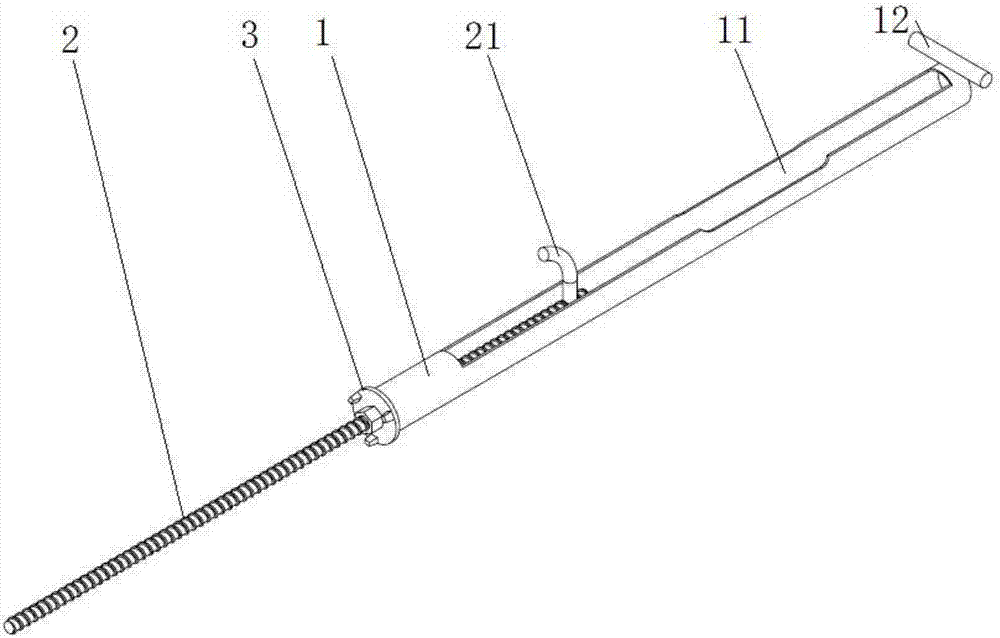

[0018] refer to figure 1 A steel bar spacing adjuster shown includes a sleeve 1 and a screw 2 .

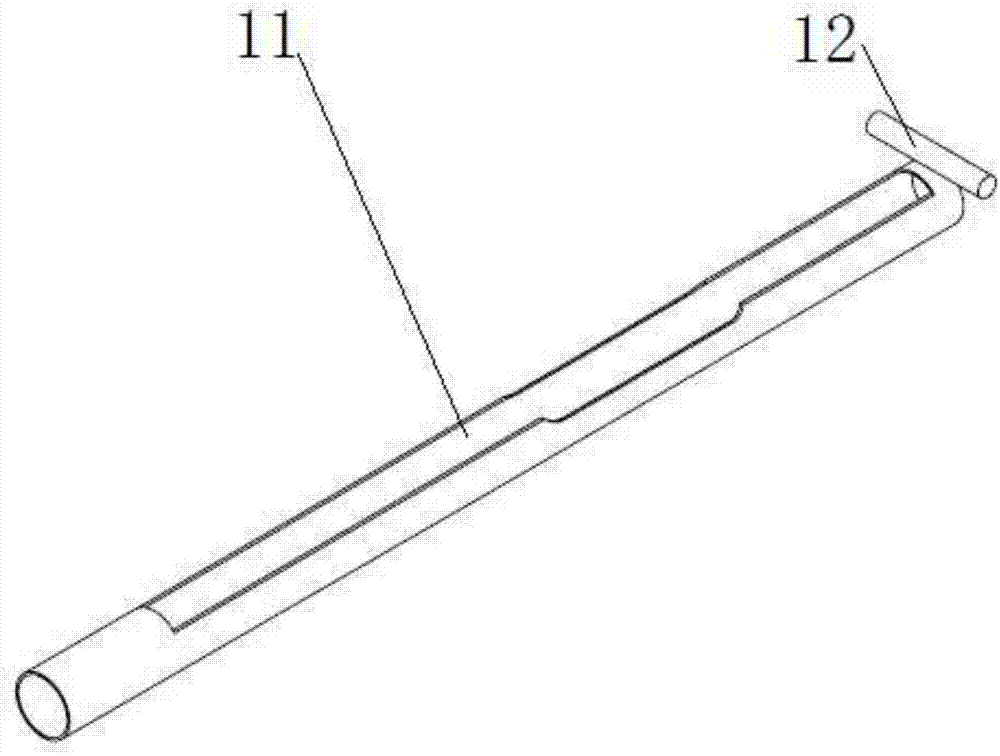

[0019] refer to figure 2 As shown, the sleeve 1 is provided with a strip-shaped hole 11 along the length direction of the sleeve, and one end of the sleeve is horizontally welded with a steel bar 12 on the same side of the strip-shaped hole 11 as a stop for adjusting the distance between the steel bars.

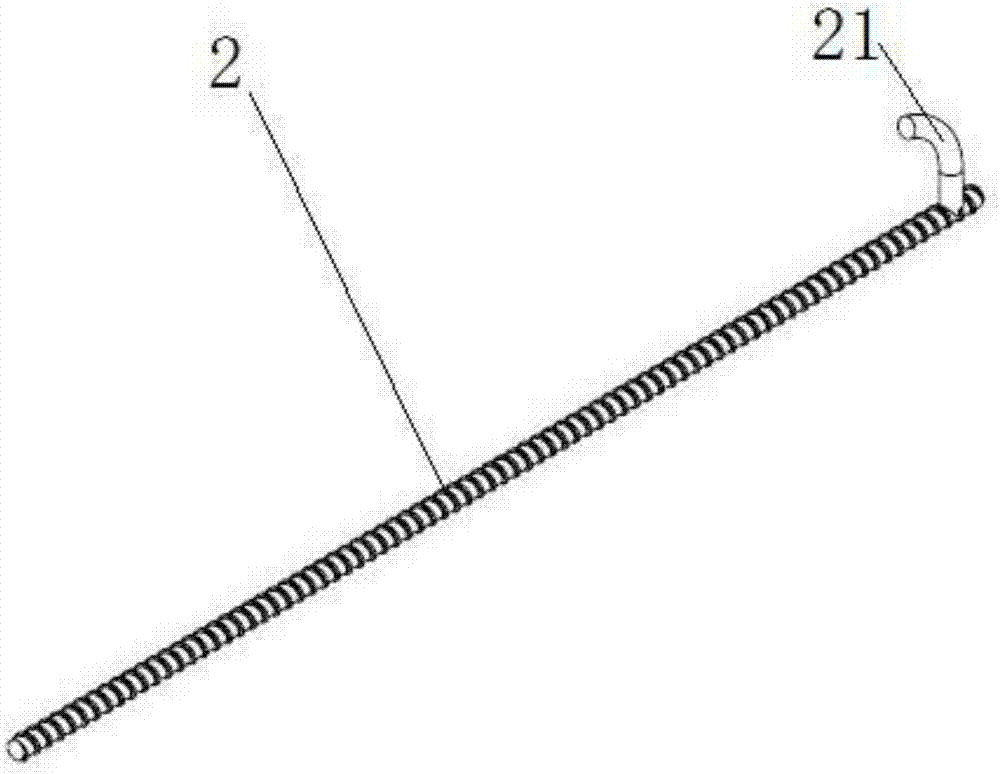

[0020] refer to image 3 As shown, one end of the screw 2 extends into the casing 1 and a hook-shaped steel bar 21 is vertically welded at this end. The bending direction of the steel bar 21 is opposite to the steel bar 12, and always extends out of the strip-shaped hole groove. 11 above, this serves as another limiter for adjusting the spacing between steel bars.

[0021] A nut 3 is mounted on the shaft where the screw 2 does not enter the bushing 1, refer to Figure 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com